Fucoidan sulfate and preparation method thereof

A technology of polyfucoidan sulfate and conditions, which is applied in the field of preparation of fucoidan sulfate, can solve the problems of increasing the difficulty of separation and purification of degradation products, high degradation temperature, and complicated enzyme screening process, etc. The effect of high content of algalose and sulfate ester groups, high product purity, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] [Example 1] Preparation of Fucoidan Sulfate

[0026] Take 1 kg of dried plum blossom slices (about 1.5 mm in thickness), put them into a reaction tank (25 L), add 8 L of 0.5 mol / L NaOH solution, and stir and extract at 40 ° C for 3 hours. After cooling, adjust the pH value to 6-7 with 6mol / L hydrochloric acid, add 7L papain aqueous solution (containing papain 5g, 8×10 5 U / g), stirred at 50°C for 6 hours, then raised to 100°C for 10 minutes to inactivate the enzyme. Cool, and centrifuge to remove the precipitate. The resulting supernatant was adjusted to pH 2.5 with 6 mol / L hydrochloric acid (precipitated protein), allowed to stand at 4°C for 4 hours, and centrifuged to remove the precipitate. Adjust the supernatant to neutral, add potassium acetate to make the final concentration 1mol / L, and add ethanol to 60% (v / v), let it stand, and centrifuge to collect the precipitate (crude polysaccharide of plum flower ginseng). Dissolve the obtained precipitate in 5L of water,...

Embodiment 2

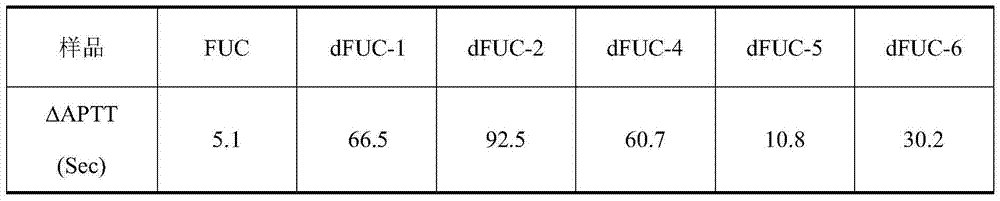

[0027] [Example 2] Preparation of oligomeric fucoidan sulfate

[0028] Hydrogen peroxide oxidative degradation of plum flower ginseng fucoidan sulfate: take 1.0 g of FUC prepared in Example 1, 2.72 g of sodium acetate trihydrate and 1.17 g of sodium chloride and dissolve them in 38 mL of water, add 2 mL of 80 mmol / L Copper acetate solution, stir to mix. Under the condition of stirring in a water bath at 35°C, the pH of the reaction was controlled to 7.5, and 10% (v / v) H 2 o 2The degradation reaction was 3 hours. Add 0.1g Na 2 EDTA terminates the reaction. The reaction solution was concentrated under reduced pressure, and 2.5 times the volume of 95% ethanol was added for precipitation, left to stand, and centrifuged to collect the precipitate. The precipitate was dissolved in water, dialyzed with a dialysis bag with a molecular weight cut-off of 1000Da, and freeze-dried to obtain 0.68 g of oligomeric plum flower ginseng fucoidan sulfate (dFUC-1).

Embodiment 3

[0029] [Example 3] Preparation of oligomeric fucoidan sulfate

[0030] Hydrogen peroxide oxidative degradation of plum flower ginseng fucoidan sulfate: take 1.0 g of FUC prepared in Example 1, and degrade it according to the method of Example 2, H 2 o 2 Degradation reaction 6 hours. The post-treatment method is the same as in Example 2, and finally 0.47 g of oligomeric plum flower ginseng fucoidan sulfate (dFUC-2) is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com