Polymer hydrogel and preparation method thereof

A polymer hydrogel and polymer technology, applied in the field of polymer hydrogel, can solve the problems of cumbersome preparation process, poor comprehensive performance and high mechanical strength, and achieve a wide range of applications, high tensile strength, and easy availability of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

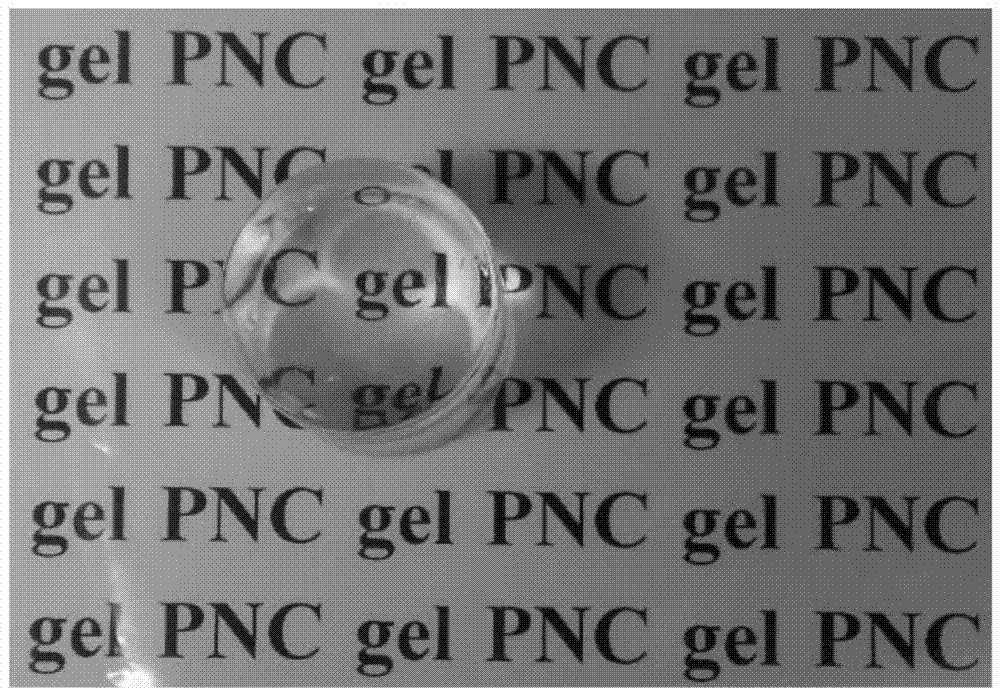

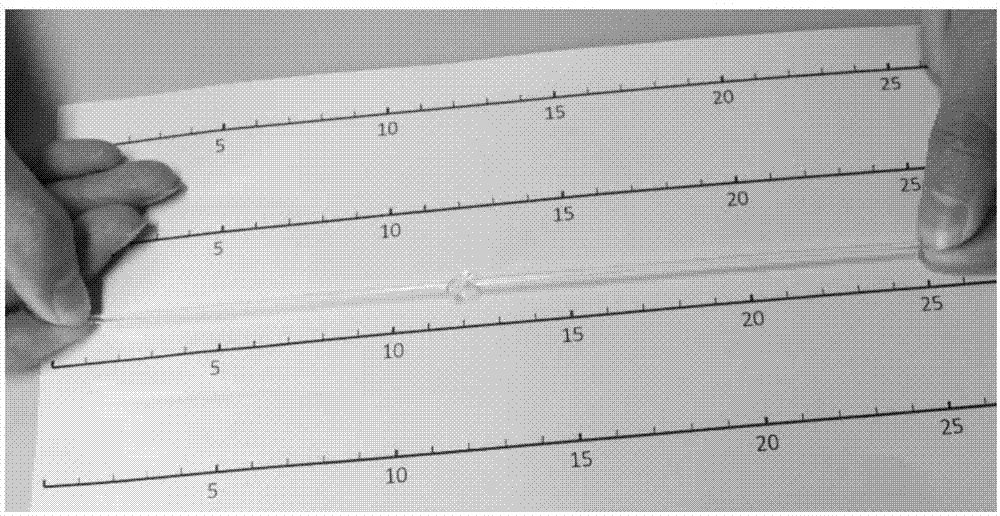

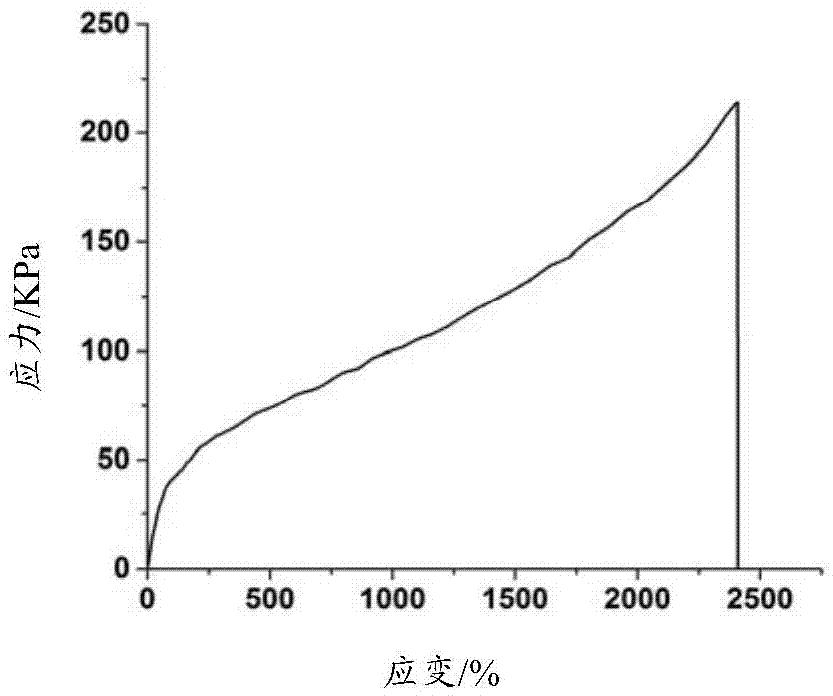

Embodiment 1

[0068] (1) Dissolve vinyl-functionalized silica particles with a particle size of 3nm in deionized water, disperse them uniformly by ultrasonication for 30 minutes, then add acrylamide monomer, stir for 10 minutes, and add the initiator after it dissolves Ammonium persulfate was dissolved by stirring for 10 minutes to obtain a mixed solution containing vinyl-functionalized silica particles, acrylamide and ammonium persulfate. Wherein, the mass fraction of vinyl-functionalized silica particles with a particle diameter of 3 nm is 0.14%, the mass fraction of acrylamide is 25%, the mass fraction of ammonium persulfate is 0.1%, and the balance is deionized water.

[0069] (2) Into the mixed solution obtained in step (1), feed nitrogen to drive oxygen for 30 minutes to 60 minutes, then pour the mixed solution into a cylindrical mold with a diameter of 5 mm, initiate free radical polymerization for 24 hours at 35° C., and pass The hydrogen bonds between the amide groups on the polyme...

Embodiment 2

[0073] (1) Dissolve silica particles with reactive functional groups with a particle size of 52nm in deionized water, disperse them uniformly by ultrasonication for 50 minutes, then add acrylamide monomer, stir for 10 minutes to dissolve, then add the initiator Potassium sulfate was dissolved by stirring for 10 minutes to obtain a mixed solution containing vinyl-functionalized silica particles, acrylamide and ammonium persulfate. Wherein, the mass fraction of vinyl-functionalized silica particles with a particle diameter of 52 nm is 0.14%, the mass fraction of acrylamide is 25%, the mass fraction of potassium persulfate is 0.2%, and the balance is deionized water.

[0074] (2) Into the mixed solution obtained in step (1), feed nitrogen to drive oxygen for 30 minutes to 60 minutes, then pour the mixed solution into a cylindrical mold with a diameter of 5 mm, initiate free radical polymerization at 30°C for 24 hours, pass The hydrogen bonds between the amide groups on the polyme...

Embodiment 3

[0077] (1) Dissolve vinyl-functionalized silica particles with a particle size of 3nm in deionized water, disperse them uniformly by ultrasonication for 30 minutes, then add acrylamide monomer, stir for 10 minutes to dissolve them, and then add the initiator Ammonium persulfate was dissolved by stirring for 10 minutes to obtain a mixed solution of vinyl-containing silicon dioxide particles, acrylamide and ammonium persulfate. Wherein, the mass fraction of vinyl-functionalized silica particles with a particle diameter of 3 nm is 0.07%, the mass fraction of acrylamide is 25%, the mass fraction of ammonium persulfate is 0.1%, and the balance is deionized water.

[0078] (2) Into the mixed solution obtained in step (1), feed nitrogen to drive oxygen for 30 minutes to 60 minutes, then pour the mixed solution into a cylindrical mold with a diameter of 5 mm, initiate free radical polymerization for 24 hours at 35° C., and pass The hydrogen bonds between the amide groups on the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com