A dry distillation device for solid heat carrier and its dry distillation method

A technology of solid heat carrier and dry distillation, which is applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc. It can solve the problems of increasing the difficulty of gas-solid separation, fine particle size of semi-coke products, and large amount of dust, so as to shorten the high temperature residence time , little mechanical wear and no power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

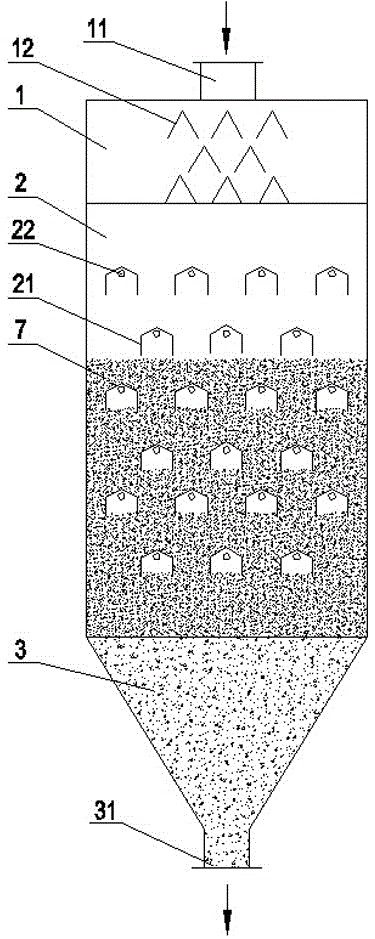

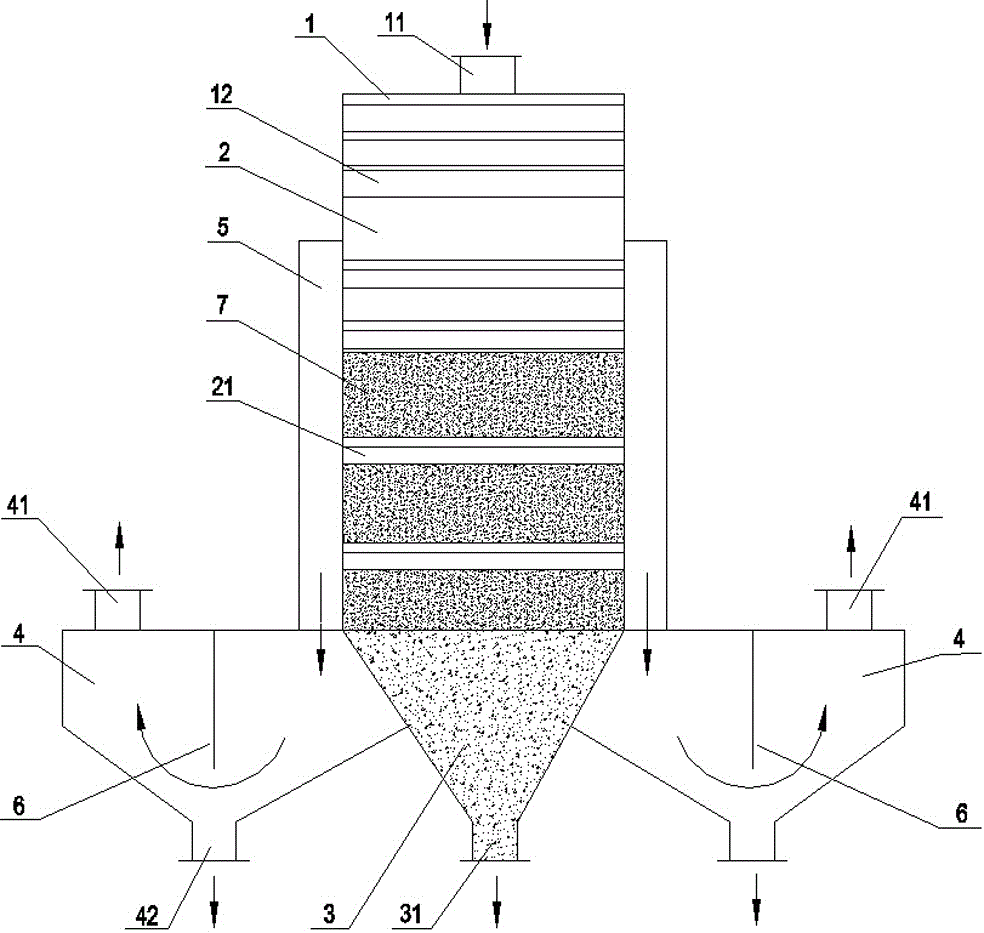

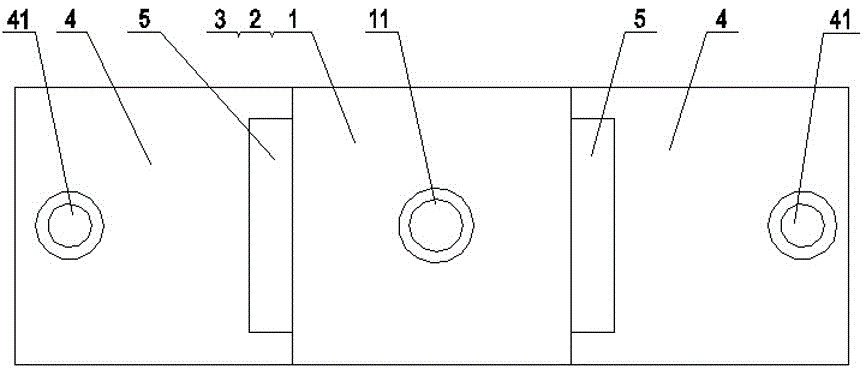

[0037] Such as figure 1 , 2 As shown in and 3, the dry distillation material is lignite particles with a particle size of 5-6mm accounting for 94% and the solid heat carrier is granular hot semi-coke.

[0038] A. The above-mentioned lignite grains and hot semi-coke are fed together from the feeding port on the upper part of the mixing chamber, mixed from top to bottom through the staggered "Λ" shaped triangular mixing plates, and then fall into the carbonization chamber to form a material layer;

[0039] B. The lignite particles in the material layer release volatile matter through pyrolysis of the heated semi-coke in the retort chamber, and the volatile matter passes through the material layer upwards and enters the "Λ"-shaped angular boxes arranged in dislocation from top to bottom, and passes through it The outlet hole is exported, and the dry distillation solid product formed after dry distillation falls down into the dry distillation solid product chamber and is discharg...

Embodiment 2

[0042] The retort material is oil shale particles with a particle size of 13-15mm, accounting for 97%, and the solid heat carrier is hot semi-coke.

[0043] A. The above-mentioned oil shale particles and hot semi-coke are put in together from the feeding port on the upper part of the mixing chamber, mixed from top to bottom through the staggered "Λ" shaped triangular mixing plates, and then fall into the carbonization chamber to form a material layer;

[0044] B. The oil shale particles in the material layer release volatile matter through hot semi-coke heating and pyrolysis in the retort chamber, and the volatile matter passes through the material layer upwards and enters the "Λ" shape arranged in dislocation from top to bottom plus the lower two side baffles In the angular box of plate structure, it is exported through the outlet hole, and the dry distillation solid product formed after dry distillation falls down into the dry distillation solid product chamber and is dischar...

Embodiment 3

[0047] The dry distillation material is lignite particles with a particle size of 8-10mm, accounting for 88%, and the solid heat carrier is hot ash.

[0048] A. Put the above-mentioned lignite particles and hot ash together from the feeding port on the upper part of the mixing chamber, mix them through the staggered "Λ" triangular mixing plates from top to bottom, and then fall into the retort chamber to form a material layer;

[0049] B. The lignite particles in the material layer are heated and pyrolyzed by the hot ash in the retort chamber to release volatile matter, and the volatile matter passes through the material layer upwards and enters the "Λ" shape with baffles on both sides of the lower part arranged in dislocation from top to bottom. In the angular box, it is exported through the outlet hole therein, and the dry distillation solid product formed after dry distillation falls down into the dry distillation solid product chamber and is discharged through the discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com