Method for doping distribution of solar cell emitter

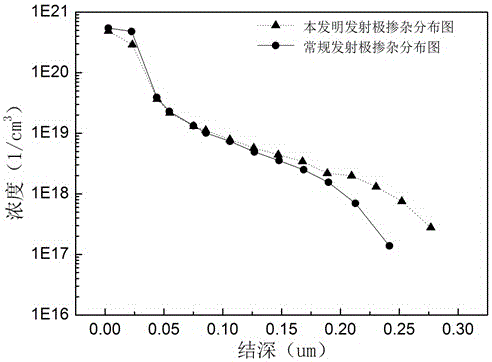

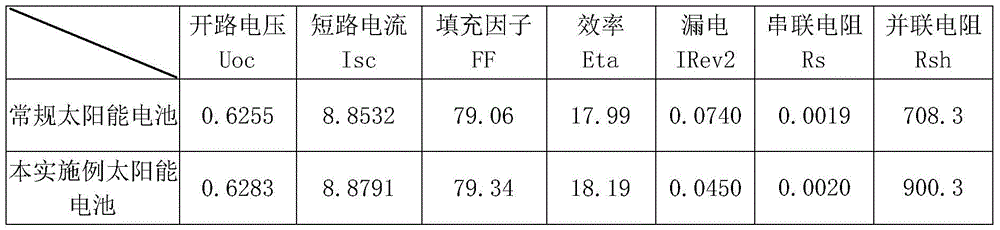

A solar cell and doping distribution technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as uneven doping concentration distribution of silicon wafers, low conversion efficiency of crystalline silicon solar cells, and reduced short-wave response of cells, etc., to achieve Improve short-wave response, improve conversion efficiency, and improve the effect of junction depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A method for doping distribution of a solar cell emitter, the process steps are as follows:

[0020] (1) Entering the boat: Insert the silicon wafer after texturing into the quartz boat and enter the diffusion furnace. The time for entering the boat is 8 minutes; the initial temperature of the diffusion furnace is 750°C. Into large nitrogen;

[0021] (2), heating up: the temperature of the diffusion furnace is raised to 810° C., and the heating time is 15 minutes. During the heating process, the diffusion furnace keeps feeding large amounts of nitrogen;

[0022] (3) Pre-oxidation: maintain the temperature of the diffusion furnace at 810° C., feed nitrogen and oxygen into the diffusion furnace to pre-oxidize the surface of the silicon wafer, and the oxidation time is 10 minutes. Oxygen volume percentage is 10%;

[0023] (4) The first source diffusion: maintain the temperature of the diffusion furnace at 810°C, feed large nitrogen, oxygen, and small nitrog...

Embodiment 2

[0032] Embodiment 2: roughly the same as Example 1, the difference is that the volume percentage of oxygen is 7% during the pre-oxidation, and the volume percentage of the small nitrogen carrying phosphorus source is 17% during the first source diffusion, and the second time source diffusion The volume percentage of phosphorus-carrying source nitrogen is 12%.

Embodiment 3

[0033] Embodiment 3: roughly the same as Example 1, the difference is that the volume percentage of oxygen is 11% during the pre-oxidation, and the volume percentage of nitrogen carrying phosphorus source is 18% during the first source diffusion, and the second time source diffusion The volume percentage of phosphorus-carrying source nitrogen is 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com