Construction and application of shuttle vector between Escherichia coli and Lactobacilli

A technology of Escherichia coli and shuttle vector, applied in the field of microbial genetic engineering, can solve the problems of great impact on human health, teratogenicity, food poisoning, etc., and achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, Extraction and Identification of Lactobacillus plantarum Zhang-LL Endogenous Plasmid

[0034] 1. Extraction of Lactobacillus plantarum Zhang-LL endogenous plasmid

[0035] A single colony of Lactobacillus plantarum Zhang-LL was picked, inoculated in 5 mL of MRS medium, and cultured at 37°C for 16 hours. Centrifuge the bacterial solution at 5,000rpm for 5min, discard the supernatant, resuspend the bacterial solution in 250μl buffer I (20mg / mL lysozyme, 50mM glucose, 25mM Tris-Cl, 10mM EDTA, pH 8.0), and place at 37°C for 1h , add 250 μl of buffer II (0.2N NaOH, 1% SDS), mix well, leave at room temperature for 5 minutes, add 350 μl of buffer III (3M potassium acetate, 2M acetic acid), mix well, and leave at room temperature for 10 minutes. Centrifuge at 12,000 rpm for 10 min, pipette 700 μl of the supernatant into a new centrifuge tube, add 700 μl of phenol:chloroform:isoamyl alcohol (25:24:1) solution, shake vigorously and mix well. Centrifuge at 12,000 rpm ...

Embodiment 2

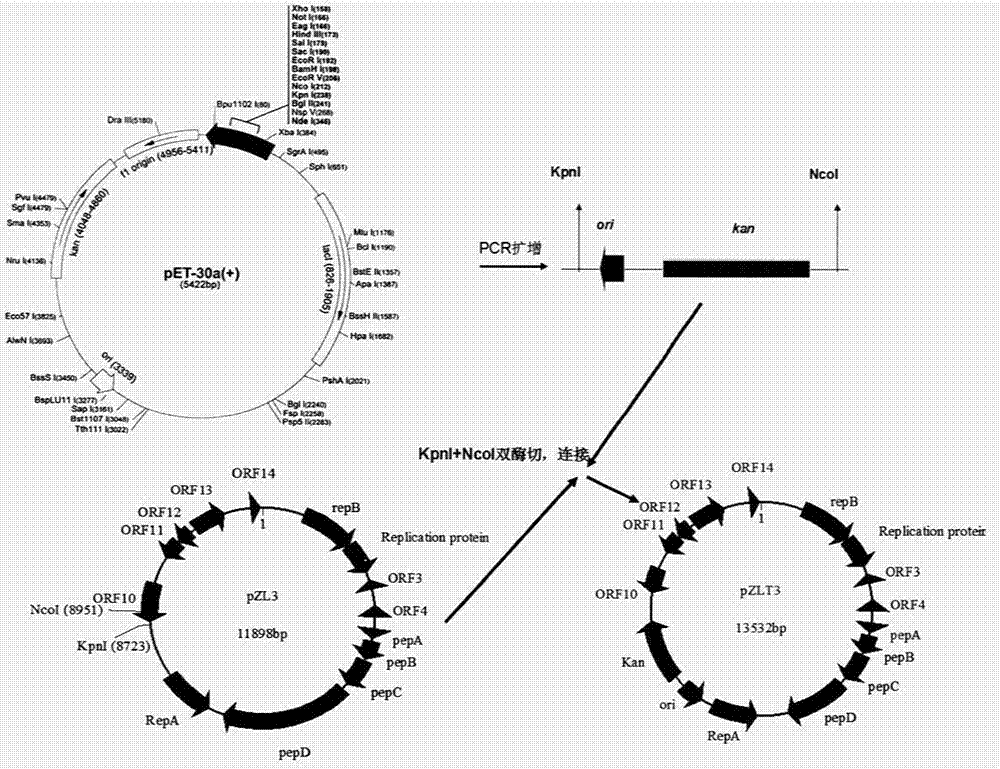

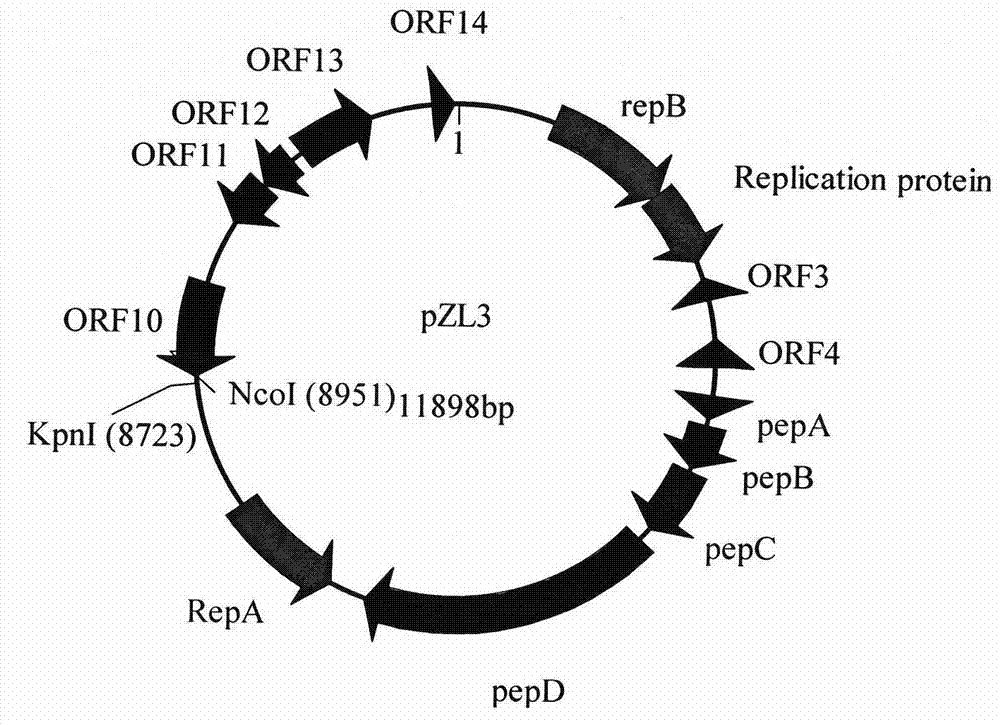

[0038] Embodiment 2, construction of Escherichia coli and Lactobacillus shuttle vector pZLT3

[0039] The construction process of the shuttle vector pZLT3 is shown in the attached figure 2 Shown:

[0040] 1. Double digestion of pZL3 plasmid

[0041] Plasmid pZL3 uses KpnI (NEB Company) and NcoI (NEB Company) for double enzyme digestion reaction, the system is as follows:

[0042] 10*Buffer 2μl KpnI 1μl NCOI 1μl pZL3 plasmid 5μl Deionized water 11μl

[0043] React at 37°C for 1 hour, and react at 65°C for 5 minutes to terminate the reaction.

[0044] 2. PCR amplification of E. coli replicon

[0045] Using the prokaryotic expression vector pET30a(+) as a template, the E. coli replicon and the kanamycin resistance cassette were amplified. The upstream primer sequence: 5'AGGTACCCCCCAGTCAC 3', the downstream primer sequence: 5'CCATGGCGCTCATGAATTAATT 3', and the reaction conditions were as follows:

[0046] 10*Buffer 2.5μ...

Embodiment 3

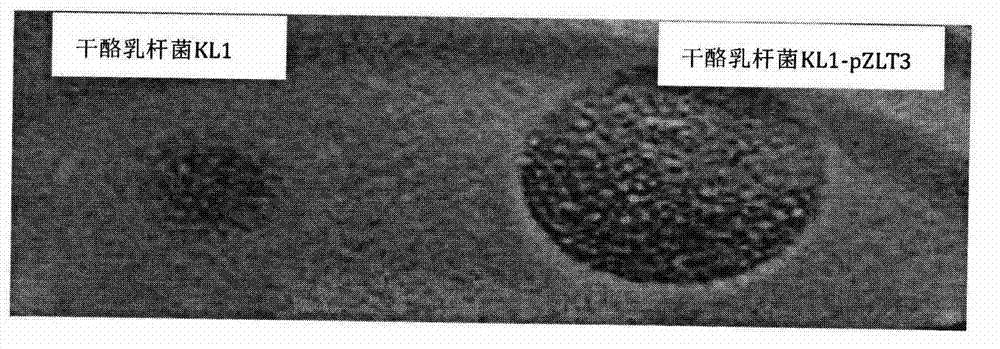

[0057] Example 3, the application of Escherichia coli and Lactobacillus shuttle vector pZLT3 expressing lactobacillus

[0058] 1. Escherichia coli-Lactobacillus shuttle vector pZLT3 transformed into Lactobacillus casei KL1

[0059] The constructed Escherichia coli-Lactobacillus shuttle vector pZLT3 is transformed into Lactobacillus casei (Lactobacillus casei) KL1 (CGMCC No.1809), and the method steps are as follows:

[0060] (1) Pick a single colony of Lactobacillus casei KL1 freshly cultivated, inoculate it in 5 mL MRS liquid medium, and culture it statically at 37° C. for 12 hours.

[0061] (2) Inoculate into MRS culture medium at a ratio of 1:20, and continue to cultivate at 37°C until the OD600 is about 0.6; transfer the culture medium to a pre-cooled 500mL centrifuge tube, place on ice for 10min; 4°C, 5,000r / m Centrifuge for 5min, and use 50mL ice-cold EPWB buffer (6mmol / L NaH 2 PO 4 (pH8.0), 1mmol / LMgCl 2 ) washed 3 times; with 50mL ice-cold EPB solution (6mmol / L NaH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com