Gas barrier film and method for manufacturing gas barrier film

A gas barrier film and gas barrier technology, which are used in the manufacture of semiconductor/solid state devices, electrical components, and electric solid state devices, etc., to achieve the effect of suppressing the reduction of gas barrier properties and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

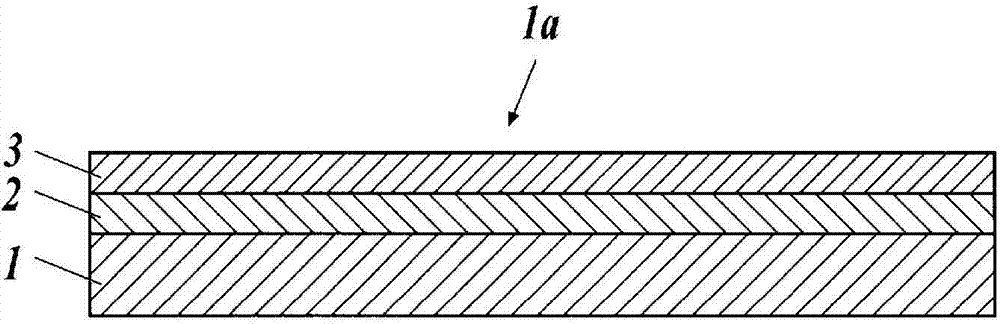

[0348] (Substrate)

[0349] As a substrate, a biaxially stretched polyethylene naphthalate film (PEN film, thickness: 100 μm, width: 350 mm, manufactured by Teijin DuPont Films Co., Ltd., trade name “TEONEX Q65FA”) was used.

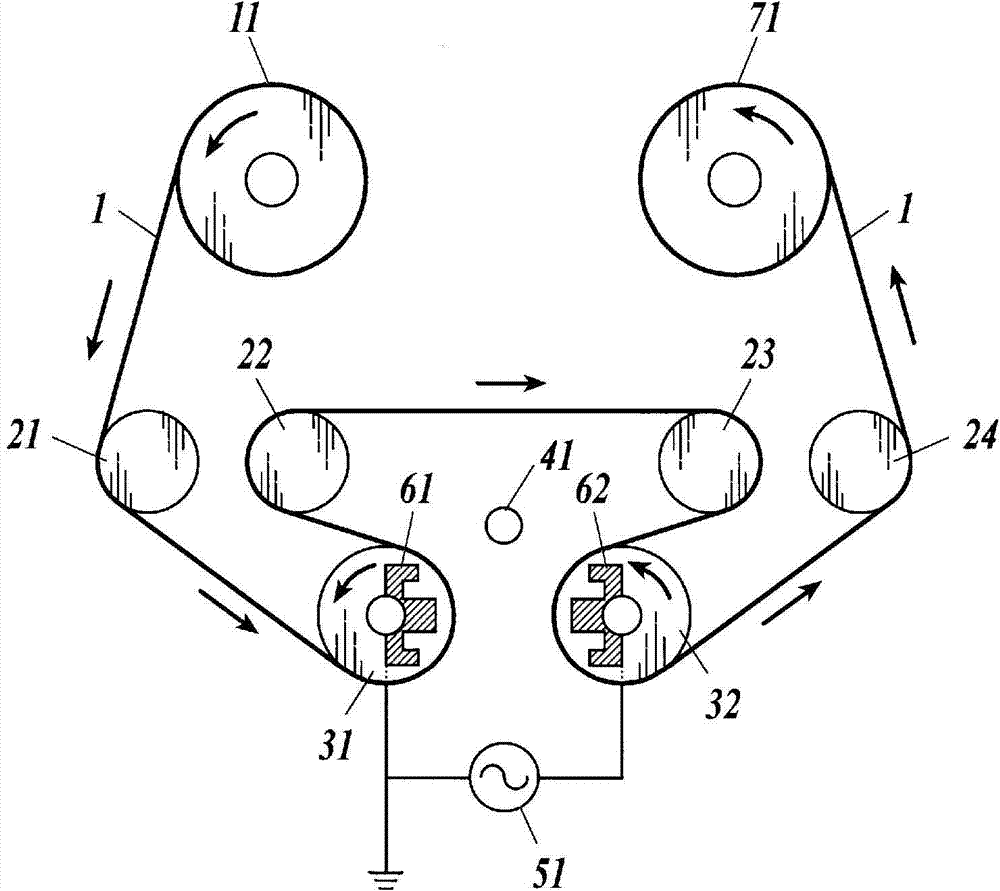

[0350] (Production of gas barrier layer)

[0351] use figure 2 In the above-mentioned apparatus, the above-mentioned substrate was mounted on the apparatus, and a gas barrier layer was formed on the substrate to have a thickness of 300 nm under the following film-forming conditions (plasma CVD conditions). At this time, make the following samples: image 3 As shown, the gas supply port moves from the vertical bisector of the line segment between the electrodes of the film-forming roll to the side of the film-forming roll 31 or 32 as shown in Table 1 and moves parallel to the line segment between the electrodes of the film-forming roll by 2%, The distances of 5%, 10% and 20% increase the oxygen atomic ratio at the interface of the gas barrier layer on...

Embodiment 2

[0374] Such as Figure 8 As documented, connect the 2 and 3 above figure 2 The described apparatus is a tandem plasma CVD apparatus.

[0375] Using the above-mentioned device, the positions of the gas supply ports during the preparation of Sample Nos. 1-1, 1-2, 1-3, and 1-4 of Example 1 were set in the same manner, and the gas barriers of Example 1 were prepared. Under the same conditions, CVD was repeated 2 and 3 times to fabricate gas barrier film samples with a gas barrier layer thickness of 600 nm and 900 nm.

[0376]The same as in Example 1, the XPS depth profile was measured for the sample obtained, and the silicon distribution curve, oxygen distribution curve and carbon distribution curve were obtained. As a result, the samples No.2-1, No.2-2, and No. .3-1 and No.3-2's silicon atomic ratio, oxygen atomic ratio and carbon atomic ratio meet the requirements of (i) above; the obtained carbon distribution curve has multiple definite extreme values; the maximum value of t...

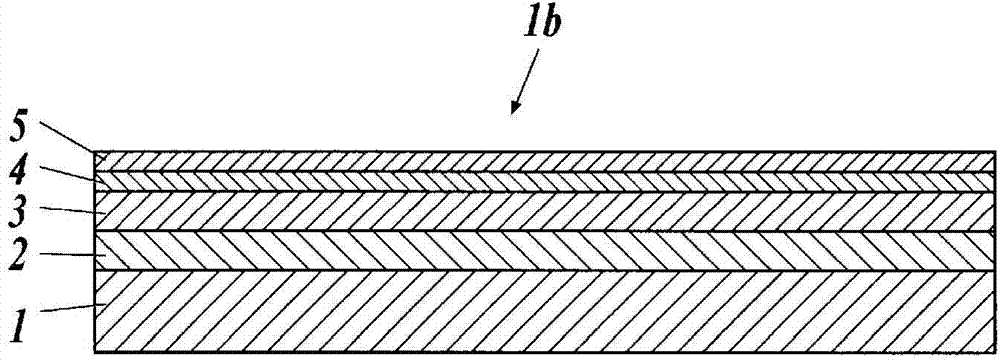

Embodiment 3

[0381] (Substrate)

[0382] As a substrate, a biaxially stretched polyethylene naphthalate film (PEN film, thickness: 100 μm, width: 350 mm, manufactured by Teijin DuPont Films Co., Ltd., trade name “TEONEX Q65FA”) was used.

[0383] (making of base layer)

[0384] After coating the easy-adhesive surface of the above substrate with a wire bar so that the layer thickness after drying is 4 μm, OPSTAR Z7501, a UV-curable organic / inorganic composite hard coating material manufactured by JSR Corporation, was dried under 80°C, 3 After drying for 10 minutes, in the air environment, use a high-pressure mercury lamp, according to the curing condition 1.0J / cm 2 Curing is carried out to form a base layer. The maximum profile height Rt(p) of the roughness curve representing the surface roughness at this time was 16 nm. It should be noted that the roughness curve is calculated using an AFM (atomic force microscope AFM: manufactured by Digital Instruments) using a probe with a stylus hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com