System and method for preparing pulverized coal fuel of pulverized-coal boiler by using coal washing tailings

A boiler fuel and coal washing technology, applied in the field of fuel pulverized coal system, can solve the problems of large power consumption, unfavorable energy saving and emission reduction, environmental protection, large dust, etc., to reduce consumption, promote energy saving and consumption reduction, and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

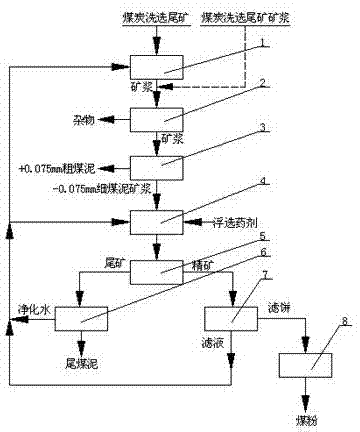

[0030] Example 1 A system for preparing pulverized coal boiler fuel pulverized coal by using coal washing tailings.

[0031] See figure 1 , the equipment used are: slurry mixing equipment 1, impurity removal and coarse cutting equipment 2, classification recovery equipment 3, pulp pretreatment equipment 4, slime separation equipment 5, slime water purification equipment 6, concentrate dehydration equipment 7, heat Drying equipment 8. In this embodiment: TJQ2500 type pulping machine is selected as the pulping equipment 1, the barrel diameter is 2500mm, the impeller speed is 400r / min, the processing capacity is 50t / h, the impurity removal and coarse cutting equipment 2 is VOSB122060 type vibrating arc screen, sieve plate The sieving size is 2.0mm, the coarse particle size is 1.0mm, the graded recovery equipment 3 adopts the LWZ1400×1800 horizontal sedimentation filter centrifugal dehydrator, and the processing capacity is 40-70t / h, and the pulp pretreatment equipment 4 adopts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com