Prepreg And Uses Of The Same

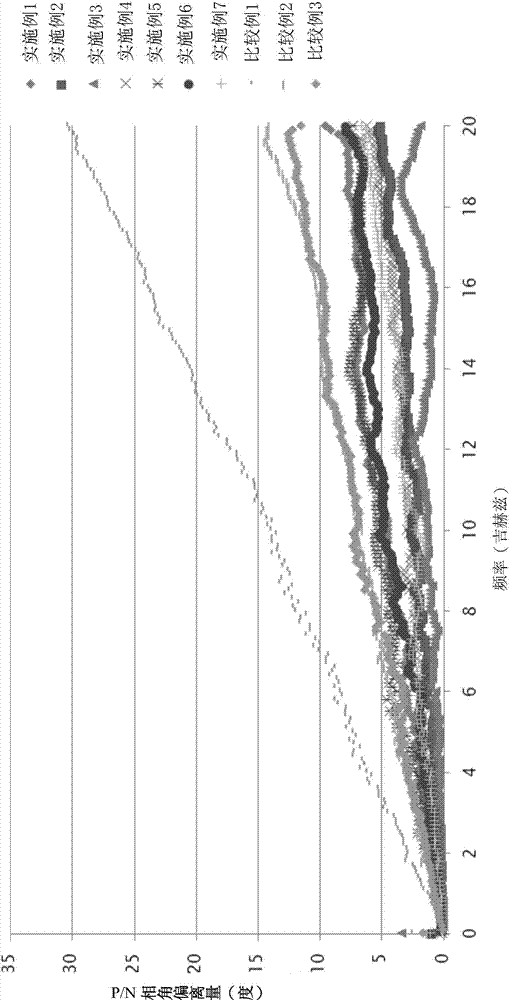

A prepreg and thermosetting technology, applied in the field of laminates, can solve the problems of signal delay or offset signal asynchronous, large influence, difference in physical properties, etc., and achieve the effect of solving signal skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

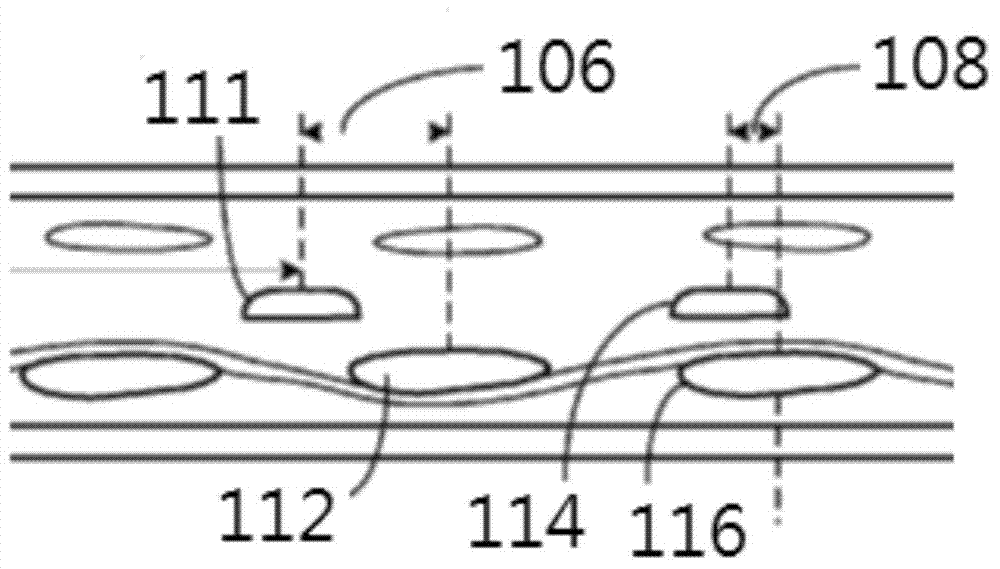

Image

Examples

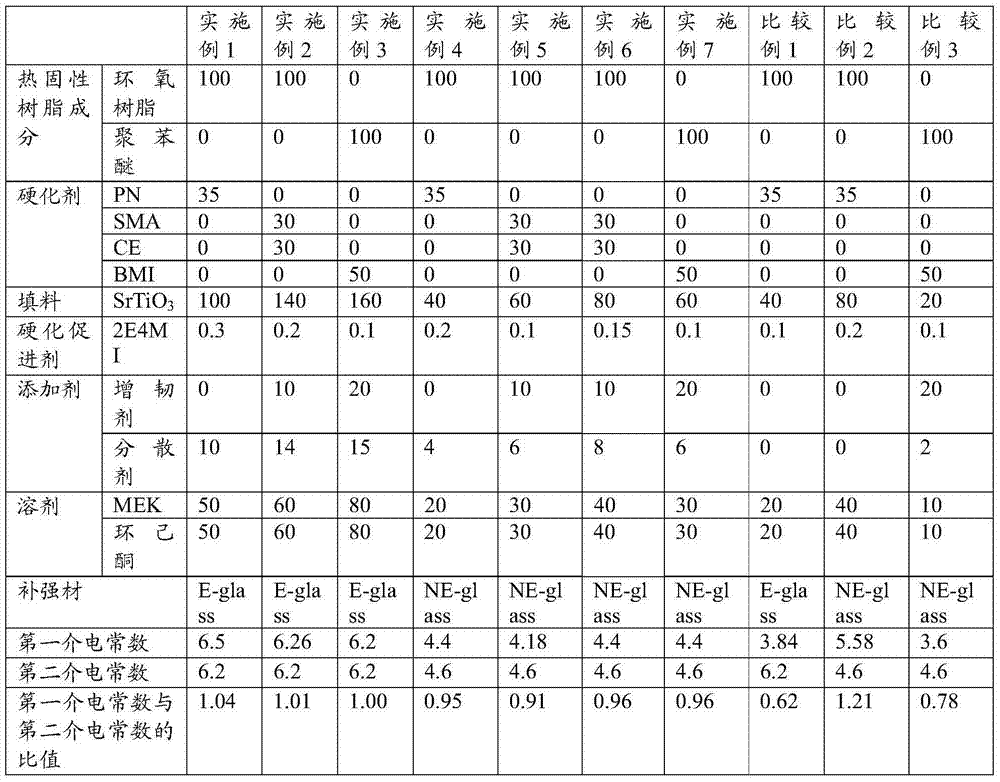

Embodiment 1

[0036] In the ratio shown in Table 2, epoxy resin (purchased from Momentive Company; model: EPON-1134) as a thermosetting resin component, phenolic resin as a hardener (purchased from Changxing Chemical Company; model: CCP8110), as a filler Strontium titanate (SrTiO 3 ) (purchased from Xiubo Electronics Co.), 2-ethyl-4-methylimidazole (2E4MI) (purchased from Shikoku Chemical Co., Ltd.) as a hardening accelerator, and dispersant (purchased from Dow Corning; model: Z-6040 ) at room temperature using a stirrer to mix for 60 minutes, then add solvent methyl ethyl ketone (MEK) (purchased from Chuanqing Chemical Company) and cyclohexanone (purchased from Zichang Company). After the resulting mixture was stirred at room temperature for 120 minutes, resin composition 1 was prepared. Measure the dielectric constant value (first dielectric constant) of the resin composition 1 and record the results in Table 2.

[0037] Take an E-grade glass fiber cloth (hereinafter referred to as "E-g...

Embodiment 2

[0040] Prepare resin composition 2 in the same manner as in Example 1, and make prepreg 2 with resin composition 2; However, change to styrene maleic anhydride copolymer (SMA) (available from Sartomer company; model: EF-40) And hydrogen ester resin (CE) (purchased from Lonza company; model: BA-230S) as hardener, increase the use of toughening agent (purchased from Momentive company; model: EPON 58006), and adjust the amount of each component, as shown in Table 2 shown.

Embodiment 3

[0042] Prepare resin composition 3 in the same manner as in Example 2, and make prepreg 3 with resin composition 3; However, polyphenylene ether (purchased from Sabic company; model: SA-90) is used as the thermosetting resin component instead, and Maleimide resin (purchased from Otsuka Pharmaceutical Company; model: BMI-70) was used as a hardening agent, and the dosage of each component was adjusted, as shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com