Preparation process of animal placenta extract

A preparation process, animal placenta technology, applied in the field of animal placenta extract preparation process, can solve the problems of low extraction efficiency, lack of extract refining process, high fat content, etc., to improve purity and quality, improve extraction efficiency, and improve activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a preparation process of an animal placenta extract, and those skilled in the art can refer to the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0027] The animal placenta and reagents used in the preparation process of the animal placenta extract provided by the present invention can be purchased from the market. Among the animal ...

Embodiment 1

[0030] Freshly frozen porcine placenta was taken, fascia and umbilical cord were removed and rinsed. After milling with a colloid mill, add 1:1 water and adjust the pH to 1.8.

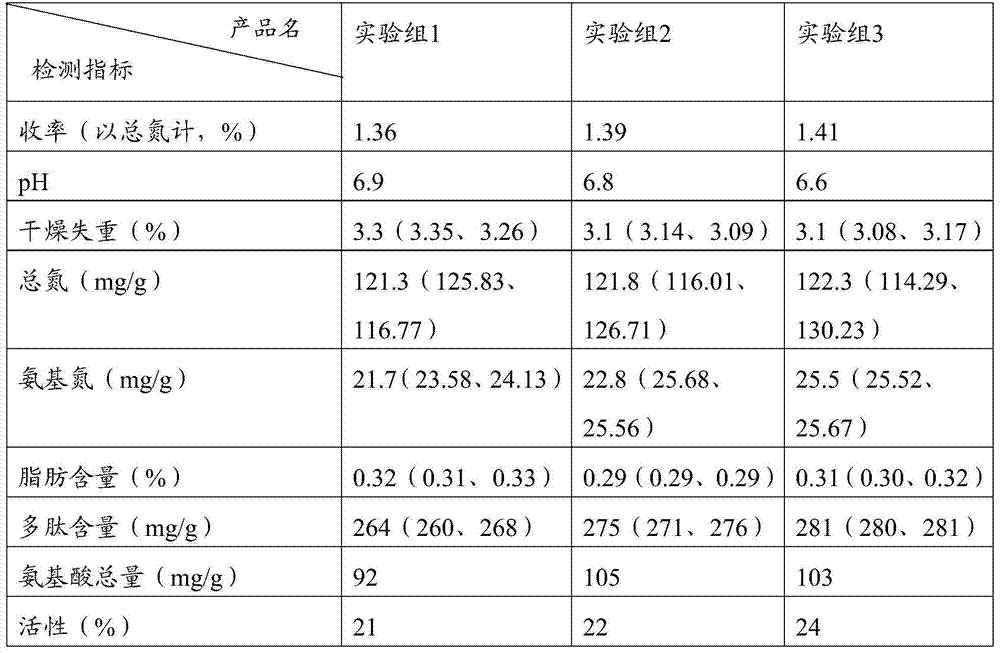

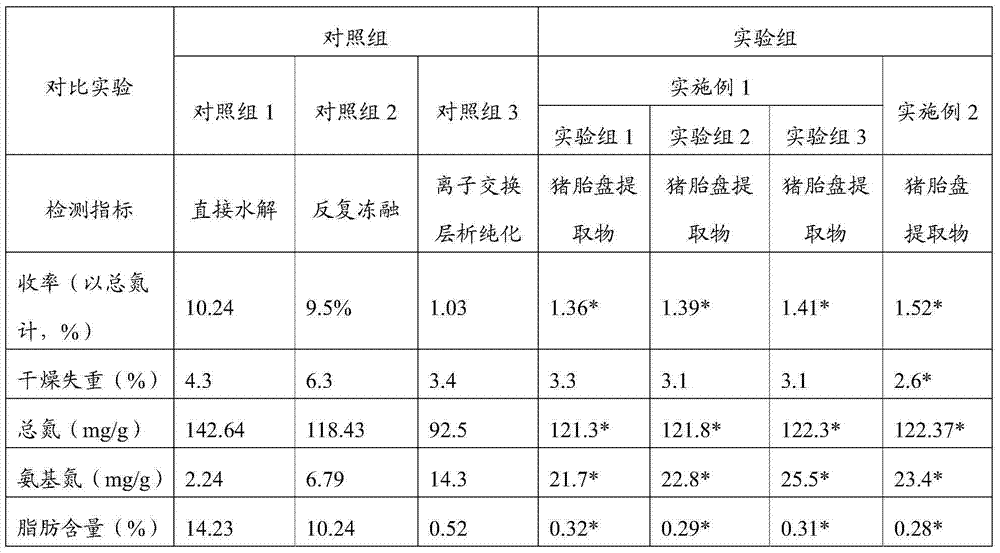

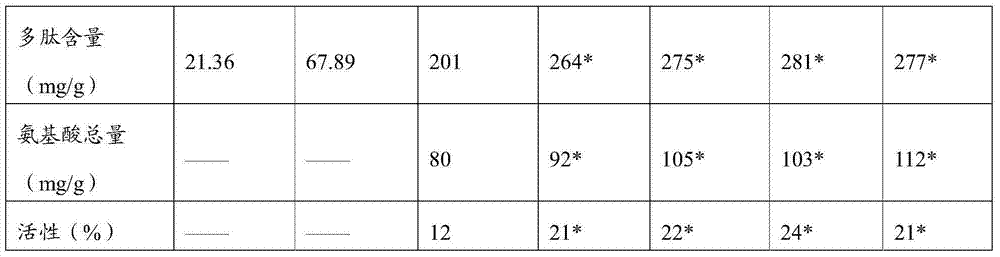

[0031] 0.4%, 0.8%, and 1.2% of pig placenta mass were added with high-activity pepsin (enzyme activity not less than 10,000 IU / g), and reacted at 40° C. for 6 hours. During the reaction, stir occasionally and keep the pH at 1.8. After the reaction, heat to 100°C for denaturation for 15 minutes to terminate the enzymatic hydrolysis reaction. After denaturation, pass through a 300-mesh non-woven fabric to filter, and collect the filtrate.

[0032] Adjust the pH of the filtrate to 7.0, add 0.04%, 0.08%, and 0.12% of the weight of pig placenta respectively to trypsin (enzyme activity not less than 3800IU / g), and react at 40°C for 4h. During the reaction, stir occasionally and keep the pH at 7.0. After the reaction, denature at 100°C for 15 minutes to terminate the enzymatic hydrolysis reaction. After ...

Embodiment 2

[0047] Take 6 kg of freshly frozen pig placenta, remove the fascia and umbilical cord, and rinse. After milling with a colloid mill, add 1:1 water and adjust the pH to 1.8.

[0048] Add 0.8% high-activity pepsin by weight of pig placenta, and react at 40° C. for 6 hours. During the reaction, stir occasionally and keep the pH at 1.8. After the reaction, heat to 100°C for denaturation for 15 minutes to terminate the enzymatic hydrolysis reaction. After denaturation, pass through a 300-mesh non-woven fabric to filter, and collect the filtrate.

[0049] Adjust the pH of the above filtrate to 7.0, add 0.08% of the weight of pig placenta trypsin, and react at 40° C. for 4 hours. During the reaction, stir occasionally and keep the pH at 7.0. After the reaction, denature at 100°C for 15 minutes to terminate the enzymatic hydrolysis reaction. After denaturation, cool to room temperature for ultrafiltration to obtain ultrafiltrate. The ultrafiltrate is a light yellow clear solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com