Analysis method for determining copper in tin-silver-copper solder through iodometry

An analytical method, tin-silver-copper technology, applied in the analysis by chemical reaction of the material, the material analysis by observing the effect on the chemical indicator, the preparation of the test sample, etc., can solve the distortion, affect the result accurately and Authenticity, solution splashing, etc., to achieve the effect of easy operation, shortening detection time, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

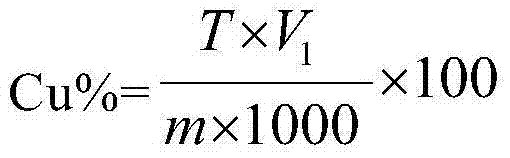

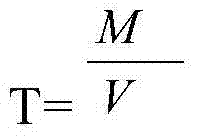

[0041] In this example, tin 50 silver 42 copper 8 For example, to measure the content of copper wherein, the specific determination method steps are as follows:

[0042] 1. Standard substance analysis

[0043] 1) Weigh the standard substance

[0044] Weigh the standard substance pure copper which is similar to the copper content in the sample, and its purity and weight are as follows:

[0045] Table 1

[0046] Standard substance name

Copper content (%)

Sample weight (g)

pure copper

99.99

0.4016

pure copper

99.99

0.4046

[0047] 2) Dissolution of standard substances

[0048] Put the weighed standard substance in a 250ml beaker, add 10ml of concentrated nitric acid, cover with a watch glass, heat to 80-100°C to dissolve the sample, continue to heat to 600°C to drive out nitrogen oxides, and cool. Transfer to a 200ml volumetric flask, make up to the mark with deionized water, and shake well;

[0049] 3) Fractionation a...

Embodiment 2

[0074] In this example, tin 30 silver 30 copper 40 For example, to measure the content of copper wherein, the specific determination method steps are as follows:

[0075] 1. Standard substance analysis

[0076] The same method as in Example 1 was adopted to obtain the titer of sodium copper thiosulfate.

[0077] 2. Sample analysis

[0078] 1) Weigh about 0.5000g tin 30 silver 30 copper 40 Sample, accurate to 0.0001g.

[0079] 2) Dissolution of the sample

[0080] Put the sample in a 250ml beaker bottle, add 10ml of concentrated sulfuric acid and heat to dissolve, take it down and cool to room temperature, add 30ml of perchloric acid, after the sample is completely dissolved, heat until white smoke of perchloric acid is emitted, divide 20 times Add 50ml of concentrated hydrochloric acid to remove tin until the solution turns from turbid to clear; Concentrate the solution to 5ml, remove it and cool it to room temperature, add 40ml of deionized water, shake well, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com