A 3D printing method for making solar cell electrodes

A technology of solar cells and 3D printing, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficulty in improving ohmic contact, affecting cell fill factor and short-circuit current, etc., achieve low solid content, increase cross-sectional area, The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

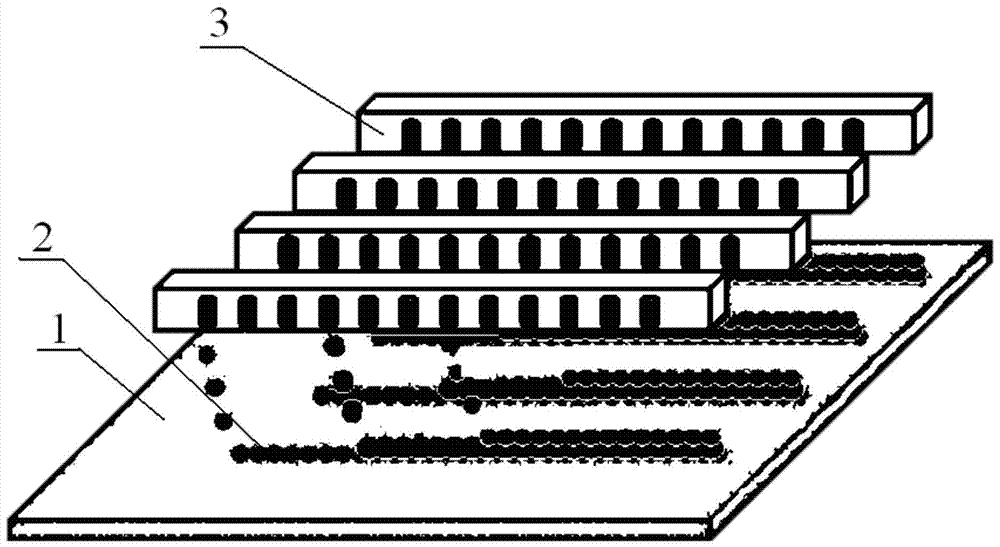

[0025] A kind of 3D printing makes solar cell electrode, its structure is as follows figure 1 As shown, it includes a substrate 1 and a conductive ink line 2. The conductive ink line 2 is a high-resolution ink containing nano-sized particles, which is directly sprayed onto the substrate 1 through a 3D printer through a nozzle 3 to form an electrode grid line to form a solar cell electrode. . 3D printing passes the conductive ink through the small nozzle 3 at high speed according to the set program, and directly sprays it to a specific position on the surface of the substrate to form an electrode pattern. The substrate used can be a silicon wafer with a thickness less than 140 μm. Due to the use of 3D printing technology, the conductive The aspect ratio of the electrode grid lines formed by the ink lines is close to 1.0, and in this embodiment, the aspect ratio of the electrode grid lines is 0.8. The solid content of the conductive ink line used is 40-70wt%, and the solid cont...

Embodiment 2

[0027] A 3D printing method for making solar cell electrodes, including a substrate and conductive ink lines. The conductive ink lines are high-resolution inks containing nano-sized particles, which are directly sprayed onto the substrate through nozzles by a 3D printer to form electrode grid lines to form solar cells. For electrodes, due to the use of 3D printing technology, the substrate used can be a silicon wafer with a thickness of less than 140 μm, the aspect ratio of the electrode grid lines formed by the printed conductive ink lines is 0.3, and the solid content of the conductive ink lines used is 40wt%. . The components of the conductive ink used include Ag, glass powder, glycol ether and Ni / Cu mixed metal, and the weight ratio of the above raw materials is 35:5:40:0.1. Since the conductive ink contains conductive metals such as Ni and Cu, nickel The contact resistance with silicon is low, which can reduce the series resistance. The nanoparticle ablation anti-reflecti...

Embodiment 3

[0029] A 3D printing method for making solar cell electrodes, including a substrate and conductive ink lines. The conductive ink lines are high-resolution inks containing nano-sized particles, which are directly sprayed onto the substrate through nozzles by a 3D printer to form electrode grid lines to form solar cells. For electrodes, due to the use of 3D printing technology, the substrate used can be a silicon wafer with a thickness of less than 140 μm, the aspect ratio of the electrode grid lines formed by the printed conductive ink lines is 1.0, and the solid content of the conductive ink lines used is 70wt%. . The components of the conductive ink used include Ag, glass powder, glycol ether and Ni / Cu mixed metal, and the weight ratio of the above raw materials is 75:25:70:25. Since the conductive ink contains conductive metals such as Ni and Cu, nickel The contact resistance with silicon is low, which can reduce the series resistance. The nanoparticle ablation anti-reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com