Aviation lamination material variable-parameter adaptive hole drilling system and method

A technology of laminated materials and adaptive controllers, applied in the direction of automatic control devices, manufacturing tools, boring/drilling, etc., to achieve the effects of ensuring continuity, saving time, avoiding delamination defects and large exit burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

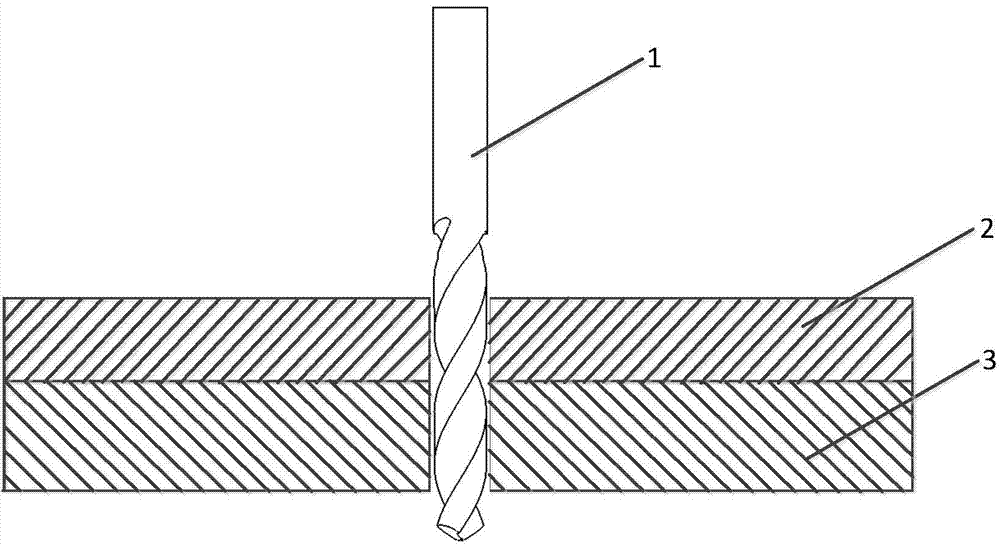

[0033] The present invention is described in further detail in conjunction with the accompanying drawings, taking the carbon fiber composite material 2 as the upper layer material, and the metal material 3 as the lower layer material as an example, as figure 1 The schematic diagram of the hole making is shown.

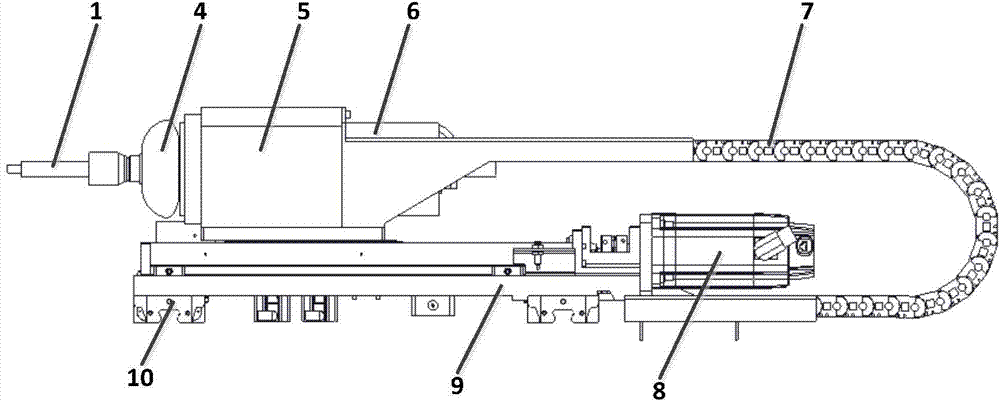

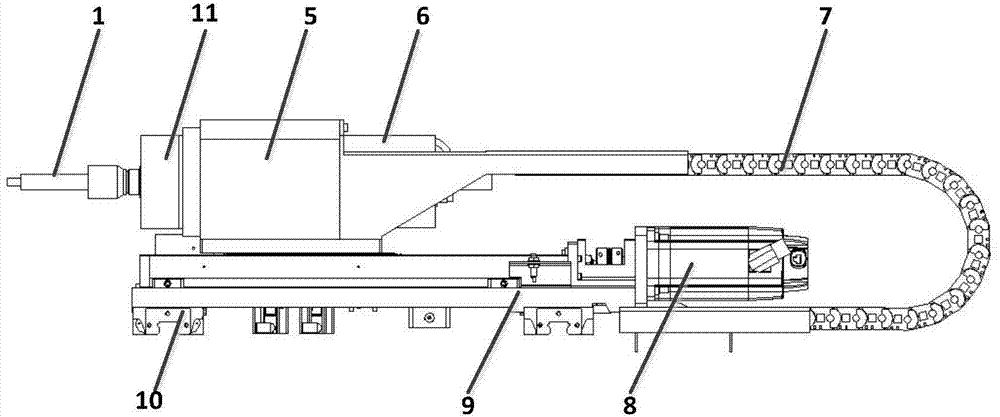

[0034] figure 2 , 3 The shown end effector is mounted on an industrial robot and is mainly used for hole making in robot automation assembly. figure 2The load cell 4 has the function of the tool handle 11, the drilling tool 1 is clamped on the load cell 4, the load cell 4 is installed on the electric spindle 6, the spindle sleeve 5 is set on the electric spindle 6, and the electric spindle The main shaft 6 is driven by a driving motor 8, and there are two vertical linear guide rails 10 under the base 9, through which the electric main shaft 6 can move freely in the plane of the base 9 through the linear guide rails 10. The encoder of the drive motor 8 can also mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com