Flue gas desulfurization wastewater treatment process for coal-fired boiler

A desulfurization wastewater and treatment process technology, which is applied in gaseous effluent wastewater treatment, water/sewage treatment, special compound water treatment, etc. The process is simple, the operation stability is improved, and the human, material and financial resources are saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

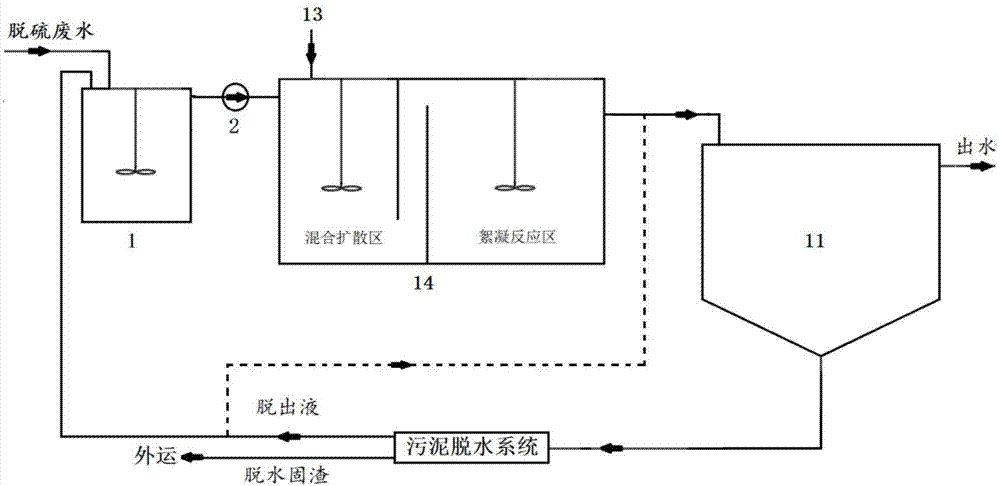

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as figure 2 Shown, coal-fired boiler flue gas desulfurization wastewater treatment process of the present invention comprises the following steps:

[0031] (1) The desulfurization wastewater produced by the limestone-gypsum wet flue gas desulfurization system is treated by the hydrocyclone, and the overflow water and the bottom flow filtration press filtrate are collected in the wastewater buffer tank 1, and the wastewater buffer tank 1 can be added with aeration according to the water quality characteristics system, the agitator is set in the waste water buffer tank 1 to prevent precipitation;

[0032] (2) The desulfurization wastewater is lifted by the wastewater lifting pump 2, and the wastewater enters the mixing and diffusion zone in the flocculation reactor 14 from the buffer tank, and is fully mixed with the added solid powder treatment agent und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com