Thermal-driving uniaxial drawing/compressive deformation device for scanning/transmission electron microscope

A uniaxial tension and compression deformation technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of complex processing technology and high cost, and achieve the effect of simple control method, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

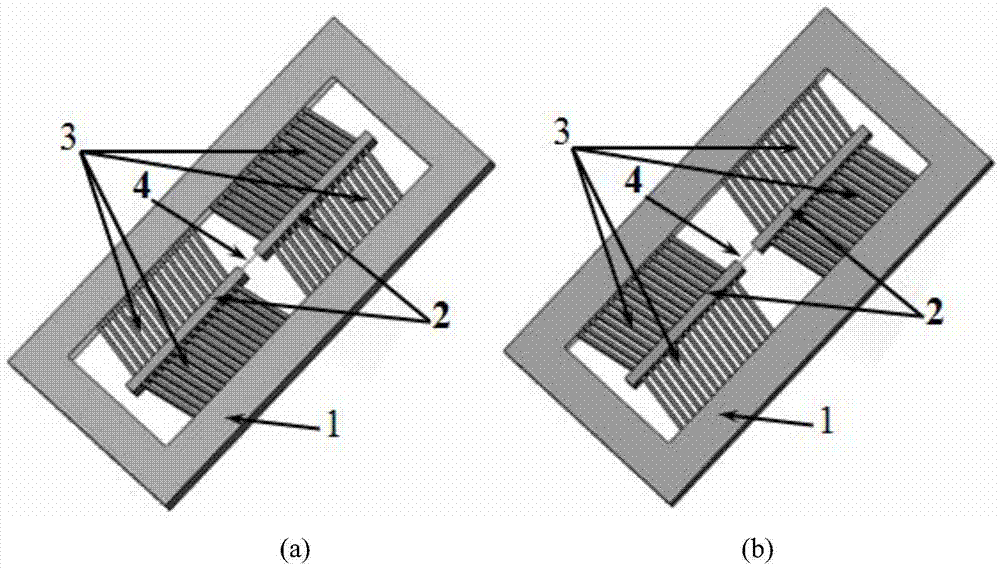

[0042] The present invention will be further described below in conjunction with accompanying drawing:

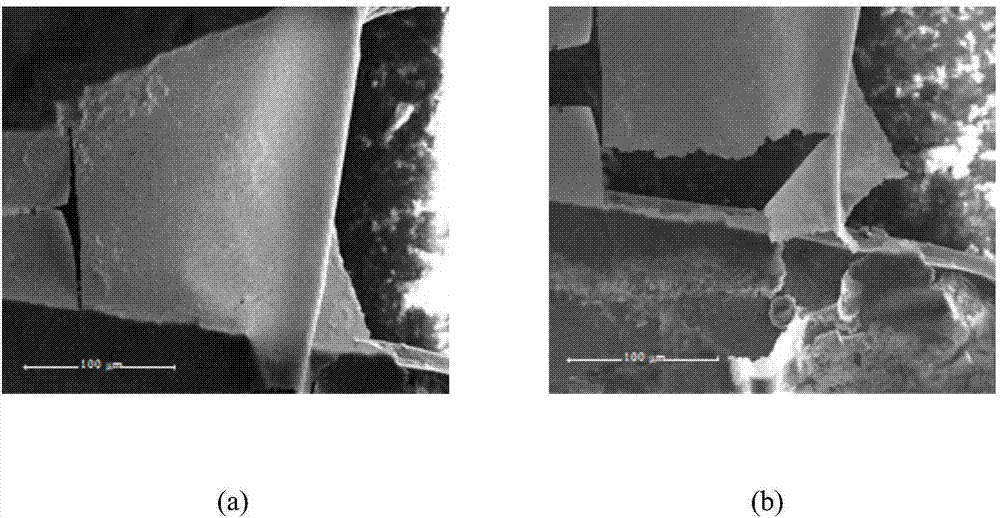

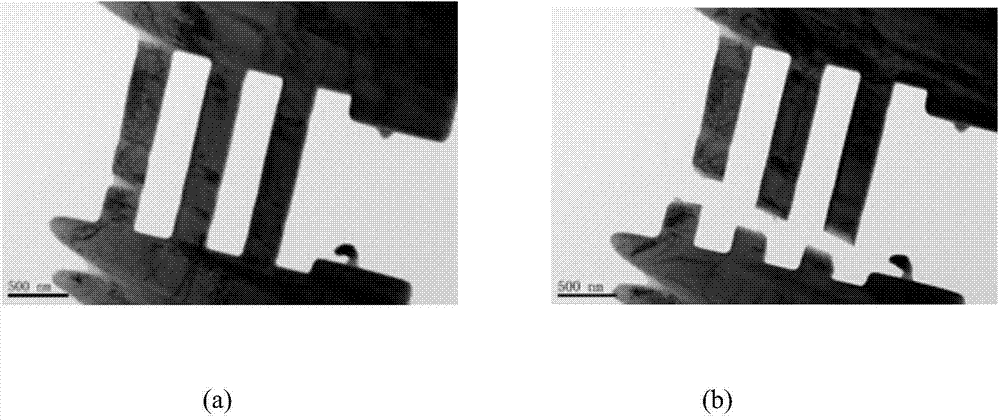

[0043] Choose double-sided polished 100μm thick aluminum foil, copper foil or molybdenum foil, after cleaning and drying, spin-coat photoresist positive resist on the front and back sides, and then bake the glue, and align the prepared photoresist plate with the front side of the copper foil for exposure. After immersing in the developing solution to remove the glue, the driving part pattern is obtained. The V-shaped beam of the driving part 3 has a width of 100 μm, a length of 700 μm, and an angle of 15° to the vertical direction of the stretching. The width of the central support part 2 is 1.5 mm, the length of the central support part 2 along the stretching direction is 500 μm, the width is 200 μm, and the distance between the central support part 2 along the stretching direction is 30 μm. Phosphoric acid, acetic acid and deionized water are prepared as an etching soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com