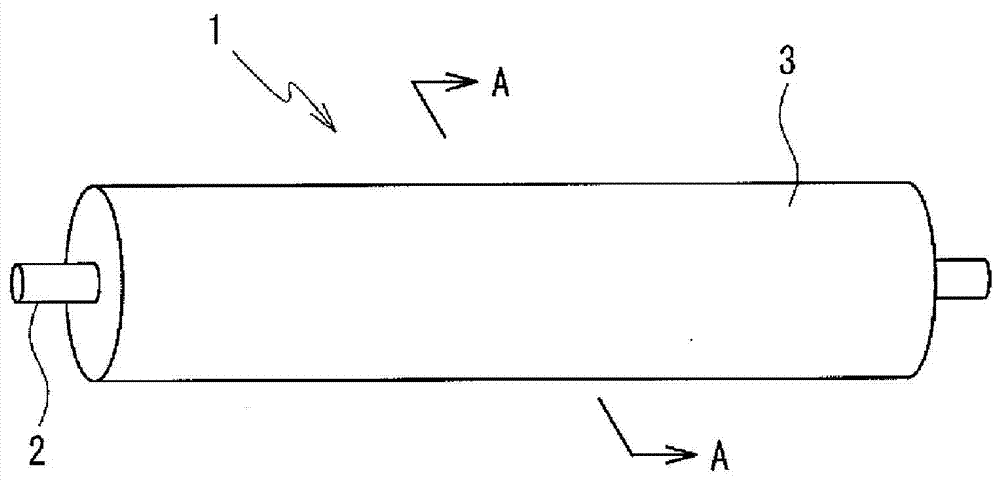

Conductive composition for electrophotographic apparatuses and conductive roll for electrophotographic apparatuses using same

An electrophotography and conductive roller technology, applied in the field of conductive rollers, can solve the problems of easy roughness, slow moving speed, and high viscosity, etc., and achieve the effects of reducing the amount of addition, reducing resistance, and improving cationicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-14

[0101] [Examples 1-1 to 1-14, Comparative Examples 1-1 to 1-4 (toner supply roller)]

[0102] Each component was prepared so that it might become the compounding ratio (unit: mass part) shown in Table 4-Table 6, and it mixed with the mixer, and the composition of the urethane foam of Example and a comparative example was prepared. Details of the materials shown in Tables 4 to 6 are as follows.

[0103] [raw materials of urethane foam]

[0104] (Polyether polyol)

[0105] ・Manufactured by Sanyo Chemical Co., Ltd., trade name "Sannitux FA703", EO content: 10%, OHv: 33 mgKOH / g

[0106] ・Manufactured by Asahi Glass Co., trade name "EXCENOL3021", EO content: 0%, OHv: 34mgKOH / g

[0107] (silicone foam stabilizer)

[0108] ・Manufactured by Toray Dou Corning Co., Ltd., product name "SRX274DL"

[0109] (foaming agent)

[0110] Distilled water: OHv: 6233mgKOH / g

[0111] (Ion Conductive Agent): Refer to Table 1 to Table 3

[0112] (catalyst)

[0113] ・Manufactured by Tosoh Corpo...

Embodiment 2-1~2-2、 comparative example 2-1

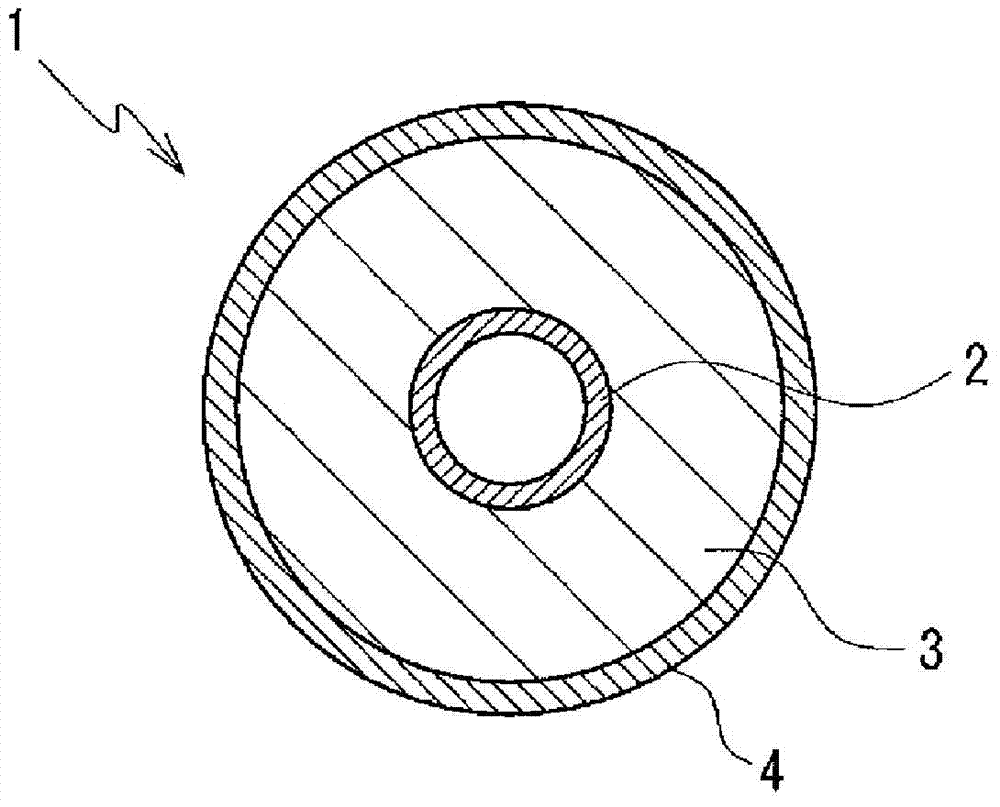

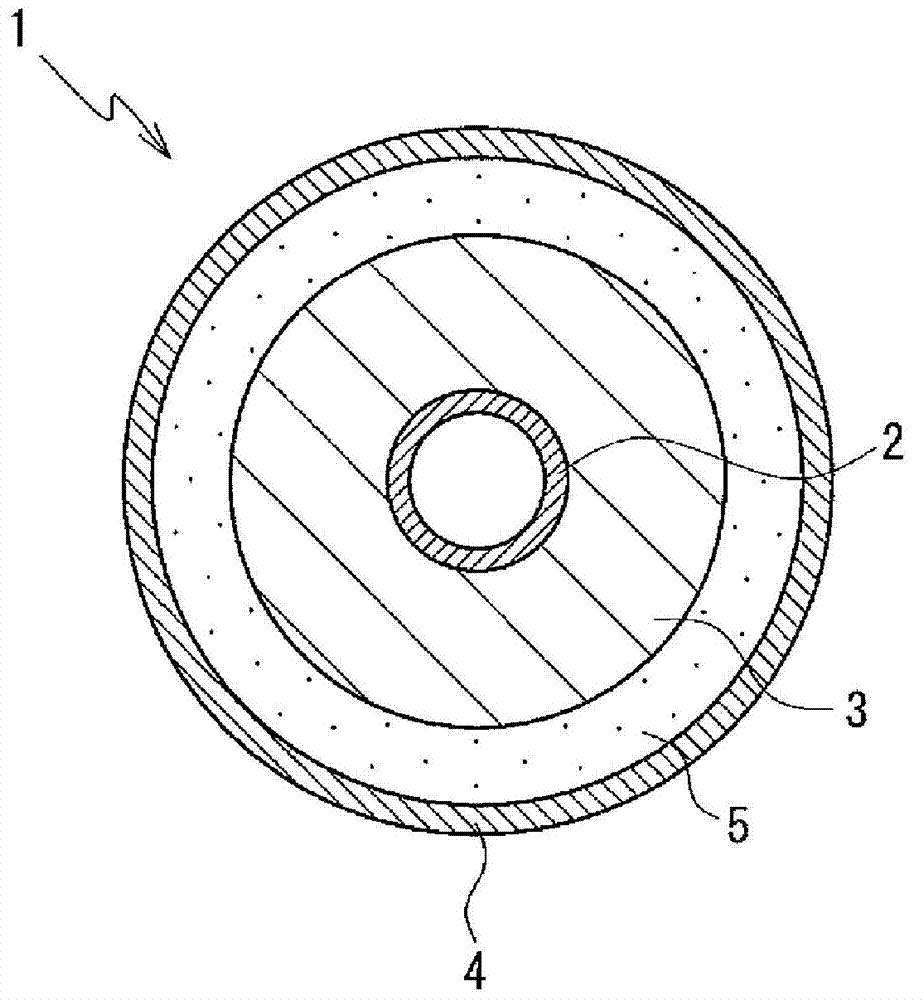

[0137] [Examples 2-1 to 2-2, Comparative Example 2-1 (Charging Roller)]

[0138] Each component was prepared so that it might become the compounding ratio (unit: mass part) shown in Table 7, and it mixed with the mixer, and prepared the composition of the basic compounding and coating film compounding of an Example and a comparative example. The details of the materials shown in Table 7 are as follows.

[0139] [Basic deployment at the grassroots level]

[0140] ・ECO: Manufactured by Daiso Co., Ltd., trade name "Ebitaroma-CG102"

[0141] ・Carbon black: manufactured by Tokai Carbon Co., Ltd., trade name "Shi-St 116"

[0142] · Peroxide: 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane: manufactured by NOF Corporation, brand name "Parhekisa 25B40"

[0143] · Ion conductive agent: refer to Table 1 and Table 3

[0144] [Surface Coating Formulation]

[0145] · N-methoxymethylated nylon

[0146] · Citric acid

[0147] · Methanol

[0148] · Ion conductive agent: refer to Table 1 a...

Embodiment 3-1~3-2、 comparative example 3-1

[0166] [Examples 3-1 to 3-2, Comparative Example 3-1 (developing roller)]

[0167] Each component was prepared so that it might become the compounding ratio (unit: mass part) shown in Table 8, and it mixed with the mixer, and prepared the composition of the basic compounding of an Example and a comparative example, and a coating film compounding. The details of the materials shown in Table 8 are as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com