Novel platelet freeze-drying treating fluid

A technology for platelets and processing liquid, which is applied in the field of platelet freeze-drying and storage, and can solve the problems of product collapse, low mechanical strength, product separation from the wall, shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

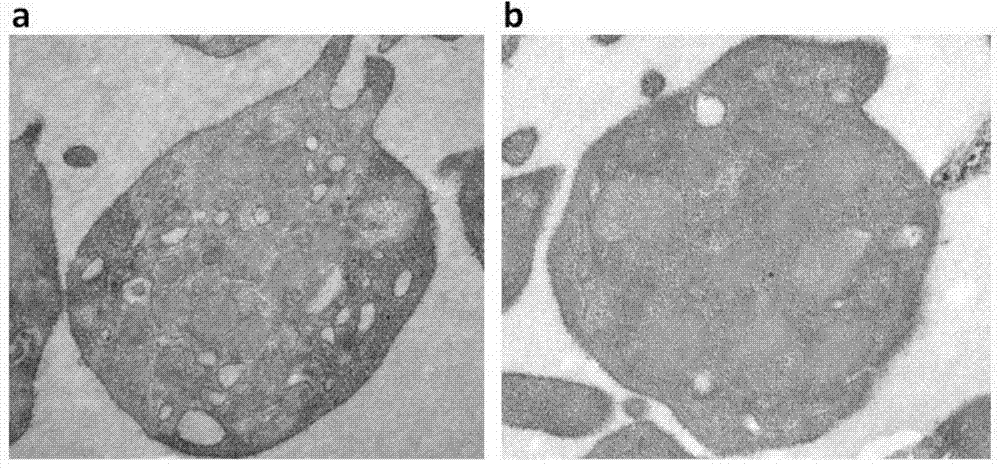

Image

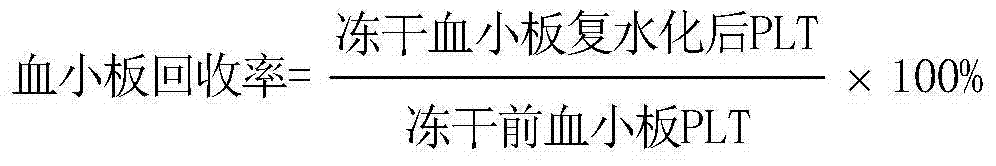

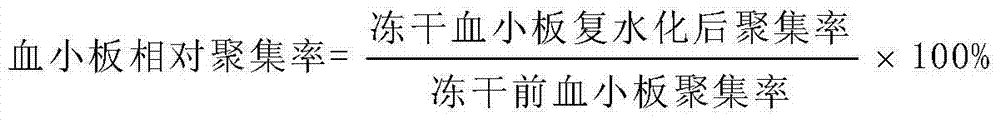

Examples

Embodiment 1

[0061] 1) Prepare the platelet freezing intervention treatment solution: add 50mmol / L trehalose and 1ug / mL PGE1 to the basic buffer solution, adjust the pH to 6.6-6.8, filter through a 0.22um filter and set aside.

[0062] 2) Prepare platelet freeze-drying buffer: add 50mmol / L trehalose, 1ug / mL PGE1 and 30% v / v plasma to the basic buffer, adjust the pH to 6.6-6.8, filter through a 0.22um filter and set aside.

[0063] 3) Intervention of platelet freezing:

[0064] 1 part of pooled platelets was centrifuged at 1500×g for 15 minutes, the supernatant was discarded and the precipitate was retained, the platelets were resuspended with the same volume of the discarded supernatant as the platelet freezing pretreatment solution, and the platelets were kept in a suspended state at 37°C for 4 hours in a shaking water bath. After the water bath, centrifuge the platelet suspension at 1500×g for 15 min, discard the supernatant and save the precipitate, and resuspend the platelets with the ...

Embodiment 2

[0069] 1) Prepare the platelet freezing intervention treatment solution: add 50mmol / L trehalose and 1ug / mL PGE1 to the basic buffer solution, adjust the pH to 6.6-6.8, filter through a 0.22um filter and set aside.

[0070] 2) Prepare platelet freeze-drying buffer: add 50mmol / L trehalose, 1ug / mL PGE1 and 40% v / v plasma to the basic buffer, adjust the pH to 6.6-6.8, filter through a 0.22um filter and set aside.

[0071] 3) Intervention of platelet freezing:

[0072] 1 part of pooled platelets was centrifuged at 1500×g for 15 minutes, the supernatant was discarded and the precipitate was retained, the platelets were resuspended with the same volume of the discarded supernatant as the platelet freezing pretreatment solution, and the platelets were kept in a suspended state at 37°C for 4 hours in a shaking water bath. After the water bath, centrifuge the platelet suspension at 1500×g for 15 min, discard the supernatant and save the precipitate, and resuspend the platelets with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com