Nanometer TiO2/ZnO anti-ultraviolet coating for PC and preparation method thereof

A UV-resistant and nano-technology, applied in coatings, polyurea/polyurethane coatings, polyester coatings, etc., can solve the problems of difficult uniform dispersion of additives and local photoaging of products, and reduce absorption speed and coating adhesion. Good, maintain the effect of transparent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

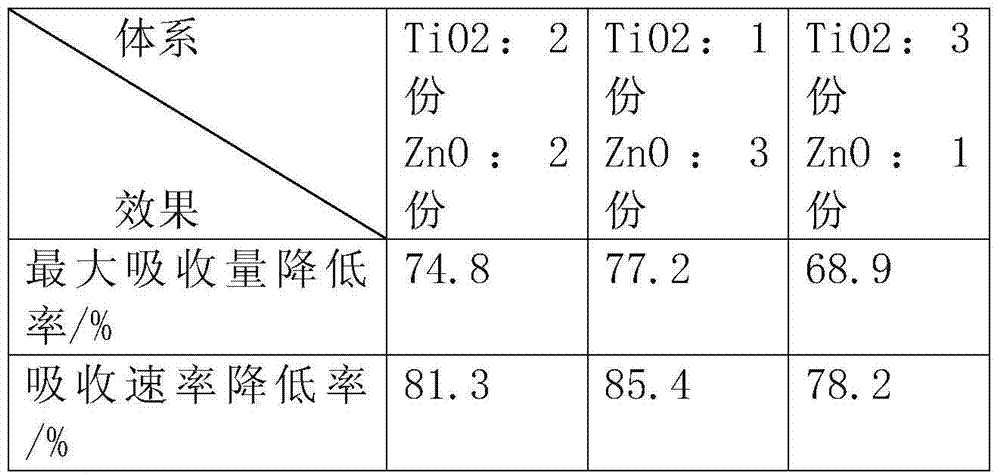

Embodiment 1

[0034] Nano TiO 2 The chelate is prepared by isobutyric acid modification and precipitation method, which are lipophilic nanoparticles with a particle size of 40nm to 100nm; the nano ZnO is coated with a stabilizer dioctyl pyrophosphate titanium, and the particle size is 20nm to 100nm. Treated Nano TiO 2 and nano-ZnO in a vacuum oven, and dried at 40° C. to 60° C. for 24 hours for later use.

[0035] Mix 50kg of polyester acrylate oligomer and 35kg of active monomer in a stirrer, heat up to 40-60°C, stir at a speed of 30r / min for 20min, and adjust the viscosity to 400cps. Then take by weighing the nano-TiO treated with surface-modified nano-ZnO 2kg and stabilizer 2 2kg was added to the above mixed solution, and the temperature was raised to 100-120°C for secondary stirring and mixing at a stirring speed of 50r / min for 2h. After lowering the temperature to 40-60°C, add 10kg of benzophenone or benzoin dimethyl ether and 1kg of N-alkyl aspartic acid-β-alkyl ester or Nβ-acyl-L...

Embodiment 2

[0037] Nano TiO 2 The chelate is prepared by isobutyric acid modification and precipitation method, which are lipophilic nanoparticles with a particle size of 40nm to 100nm; the nano ZnO is coated with a stabilizer dioctyl pyrophosphate titanium, and the particle size is 20nm to 100nm. Treated Nano TiO 2 and nano-ZnO in a vacuum oven, and dried at 40° C. to 60° C. for 24 hours for later use.

[0038] Mix 50kg of polyester acrylate oligomer and 35kg of active monomer in a stirrer, heat up to 40-60°C, stir at a speed of 30r / min for 20min, and adjust the viscosity to 400cps. Then take the nano-ZnO 2kg of the surface modification and the nano-TiO treated by the stabilizer with spare 2 4kg was added to the above mixed solution, and the temperature was raised to 100-120°C for secondary stirring and mixing at a stirring speed of 50r / min for 2h. After lowering the temperature to 40-60°C, add 8kg of benzophenone or benzoin dimethyl ether and 1kg of N-alkyl aspartic acid-β-alkyl est...

Embodiment 3

[0040] Nano TiO 2The chelate is prepared by isobutyric acid modification and precipitation method, which are lipophilic nanoparticles with a particle size of 40nm to 100nm; the nano ZnO is coated with a stabilizer dioctyl pyrophosphate titanium, and the particle size is 20nm to 100nm. Treated Nano TiO 2 and nano-ZnO in a vacuum oven, and dried at 40° C. to 60° C. for 24 hours for later use.

[0041] Mix 35kg of polyester acrylate oligomer and 50kg of active monomer in a stirrer, heat up to 40-60°C, stir at a speed of 30r / min for 20min, and adjust the viscosity to 400cps. Then take the nano-ZnO 2kg of the surface modification and the nano-TiO treated by the stabilizer with spare 2 2kg was added to the above mixed solution, and the temperature was raised to 100-120°C for secondary stirring and mixing at a stirring speed of 50r / min for 2h. After lowering the temperature to 40-60°C, add 10kg of benzophenone or benzoin dimethyl ether and 1kg of N-alkyl aspartic acid-β-alkyl est...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com