A solid fuel additive

An additive and additive preparation technology, applied in the field of fuel additives, can solve the problems of air conditioner loading shaking, unstable idling, and poor acceleration, and achieve the effects of increasing power output, improving performance, and improving response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

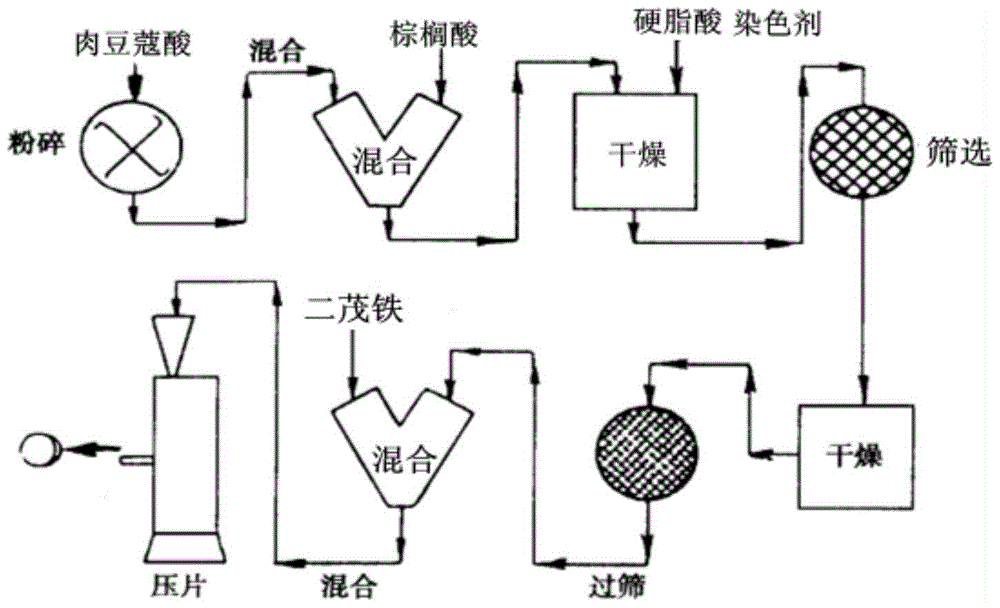

[0044] The above-mentioned solid fuel additive preparation method, such as figure 1 shown, including the following steps:

[0045] 1) Weigh 89.5-90 parts by weight of myristic acid, pulverize, and the particle size range is 4-325 μm;

[0046] 2) Add 2.0-3.0 parts by weight of palmitic acid to the pulverized myristic acid, and mix uniformly in equal increments to obtain mixture I;

[0047] 3) Add 8.0-8.5 parts by weight of stearic acid and 0-0.05 parts by weight of dyeing agent to the mixture I obtained in step 2), and mix uniformly to obtain mixture II;

[0048] 4) The mixture II obtained in step 3) undergoes the first drying (box drying, fluidized bed drying, spray drying, the temperature does not exceed 50°C, the time does not exceed 30min, and the water content does not exceed 5%) in turn. Sieve once, dry for the second time (using box drying, fluidized bed, spray drying, temperature not exceeding 50°C, time not exceeding 30min, water content not exceeding 2%), sieving fo...

Embodiment 1

[0054] A solid fuel additive, containing: 89.5kg of myristic acid, 2.0kg of palmitic acid, 8.0kg of stearic acid, and 0.08kg of ferrocene.

[0055] A method for preparing a solid fuel additive, comprising the steps of:

[0056] 1) Weigh 89.5kg of myristic acid, pulverize, and the particle size is 4 μm;

[0057] 2) Add 2.0kg of palmitic acid to the pulverized myristic acid, and mix uniformly in equal increments to obtain mixture I;

[0058] 3) Add 8.0kg of stearic acid to the mixture I obtained in step 2), and mix well to obtain mixture II;

[0059] 4) Using the box drying method, the mixture II obtained in step 3) was successively subjected to the first drying (temperature 50°C, time 30min, water content 5%), the first sieving, and the second drying (temperature 50°C , time 30min, water content 2%), sieved for the second time to obtain dry mixture II;

[0060] 5) Add 0.08kg of ferrocene to the mixture II obtained in step 4), and mix uniformly in equal increments to obtain m...

Embodiment 2

[0063] A solid fuel additive, containing: 90kg of myristic acid, 3.0kg of palmitic acid, 8.5kg of stearic acid, 0.12kg of ferrocene, and 0.05kg of green pigment.

[0064] A method for preparing a solid fuel additive, comprising the steps of:

[0065] 1) Weigh 90kg myristic acid, pulverize, and the particle size is 325 μm;

[0066] 2) Add 3.0kg of palmitic acid to the pulverized myristic acid, and mix uniformly in equal increments to obtain mixture I;

[0067] 3) Add 8.5kg of stearic acid and 0.05kg of green pigment to the mixture I obtained in step 2), mix well to obtain mixture II;

[0068] 4) Using the fluidized bed drying method, the mixture II obtained in step 3) undergoes the first drying in sequence (the temperature is maintained at 40°C-50°C, the time is controlled between 25-30min, and the sampling test results show that the water content is 0.5%-5 %), sieving for the first time, drying for the second time (the temperature is maintained at 40°C-50°C, and the time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com