Preparation method of zrc coating

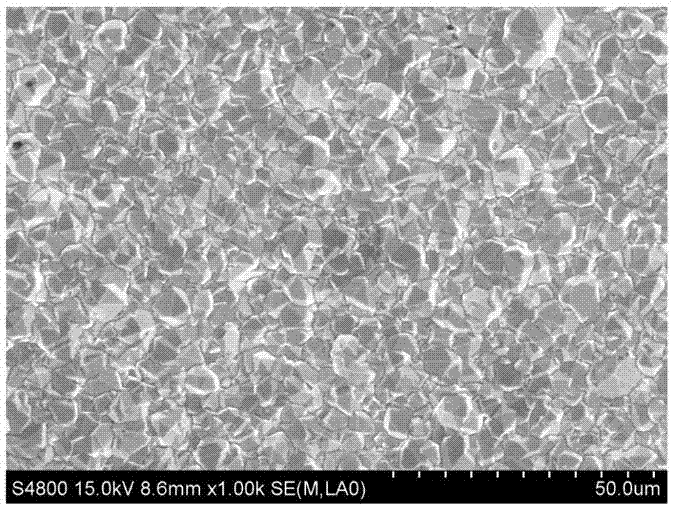

A coating and halogenation reaction technology, which is applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of low utilization rate of raw materials, high requirements for high temperature sealing performance of equipment, easy condensation of pipelines, etc. The effect of improving the utilization rate of raw materials, smooth coating surface and low equipment maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

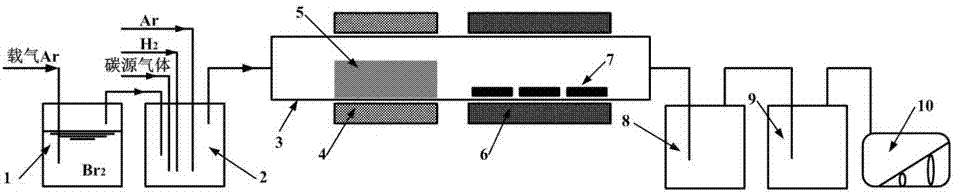

[0036] A kind of preparation method of ZrC coating of the present invention, be specifically the method that chemical vapor deposition method prepares graphite surface ZrC coating, adopt as figure 1 The shown preparation system specifically comprises the following steps:

[0037] (1) Surface treatment of the base material: Polish the graphite surface with 3000-mesh SiC sandpaper, then put the polished graphite into acetone, ultrasonically clean it for 30 minutes, and then put it into a vacuum drying oven for drying at 120°C. The drying time is 120min.

[0038] (2) Sample placement: place the graphite (substrate material 7) after the above surface treatment in the deposition area 6 of the preparation system, and place 200g of metal zirconium 5 in the halogenation reaction area 4 of the preparation system. The particle size of metal zirconium 5 is 3mm ~ 8mm.

[0039] Such as figure 1 As shown, 1 in the preparation system is Br 2 Bubble tank, in which liquid bromine kept at 0...

Embodiment 2

[0045] A kind of preparation method of ZrC coating of the present invention, be specifically the method for preparing ZrC coating on C / C composite material surface by chemical vapor deposition method, adopt as figure 1 The shown preparation system comprises the following steps:

[0046] (1) Surface treatment of the matrix material: Polish the surface of the C / C composite material with 3000-mesh SiC sandpaper, then put the sample in acetone, ultrasonically clean it for 30 minutes, and finally put it in a vacuum drying oven at 120°C for 120 minutes.

[0047] (2) Sample placement: place the surface-treated C / C composite material in the deposition zone 6, and place 200g of metal zirconium 5 in the halogenation reaction zone 4. The particle size of the metal zirconium 5 is 3 mm to 8 mm.

[0048] (3) System temperature rise: first vacuumize the chemical vapor deposition furnace 3 until the pressure in the furnace is lower than 100Pa, then pass in the protective gas argon, turn on th...

Embodiment 3

[0053] A preparation method of a ZrC coating of the present invention, specifically a method for preparing a ZrC coating on the surface of a C / SiC composite material by chemical vapor deposition, adopting such as figure 1 The shown preparation system comprises the following steps:

[0054] (1) Surface treatment of the matrix material: The surface of the C / SiC composite material was polished and polished with 3000-mesh SiC sandpaper, then the sample was placed in acetone, ultrasonically cleaned for 30 minutes, and finally dried in a vacuum oven at 120°C for 120 minutes.

[0055] (2) Sample placement: place the C / SiC composite material that has undergone the above surface treatment in the deposition area 6 . 200g of metal zirconium 5 is placed in the halogenation reaction zone 4, and the particle size of metal zirconium 5 is 3mm-8mm.

[0056] (3) System temperature rise: first vacuumize the chemical vapor deposition furnace 3 until the pressure in the furnace is lower than 100P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com