Detection method of food sweetness degree

A detection method and sweetness technology, which are applied in the field of food sweetness detection, can solve the problems of long detection time, no detection method for sweetness, influence on the accuracy of detection results, etc., and achieve the effect of convenient detection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

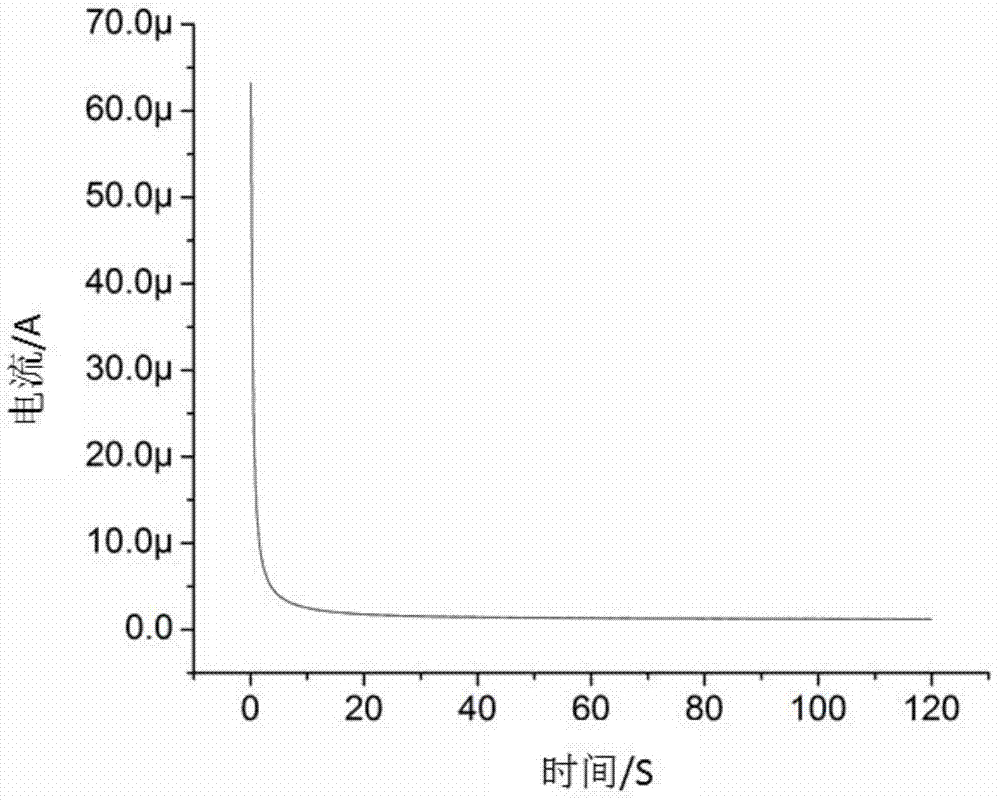

Embodiment 1

[0028] 1. Weigh graphite powder, liquid paraffin and nickel hydroxide in a ratio of 30:15:1 by weight, mix them evenly, and grind them to obtain a uniform paste.

[0029] 2. Pack the paste into a polytetrafluoroethylene casing, one end is flush with the bottom surface of the casing, and the other end is inserted into a copper rod.

[0030] 3. After the paste solidifies for 30 minutes, sand the flat end with fine sandpaper for 15 minutes to make a sweetness sensor.

[0031] 4. Prepare a potassium hydroxide solution with a concentration of 1mol / L.

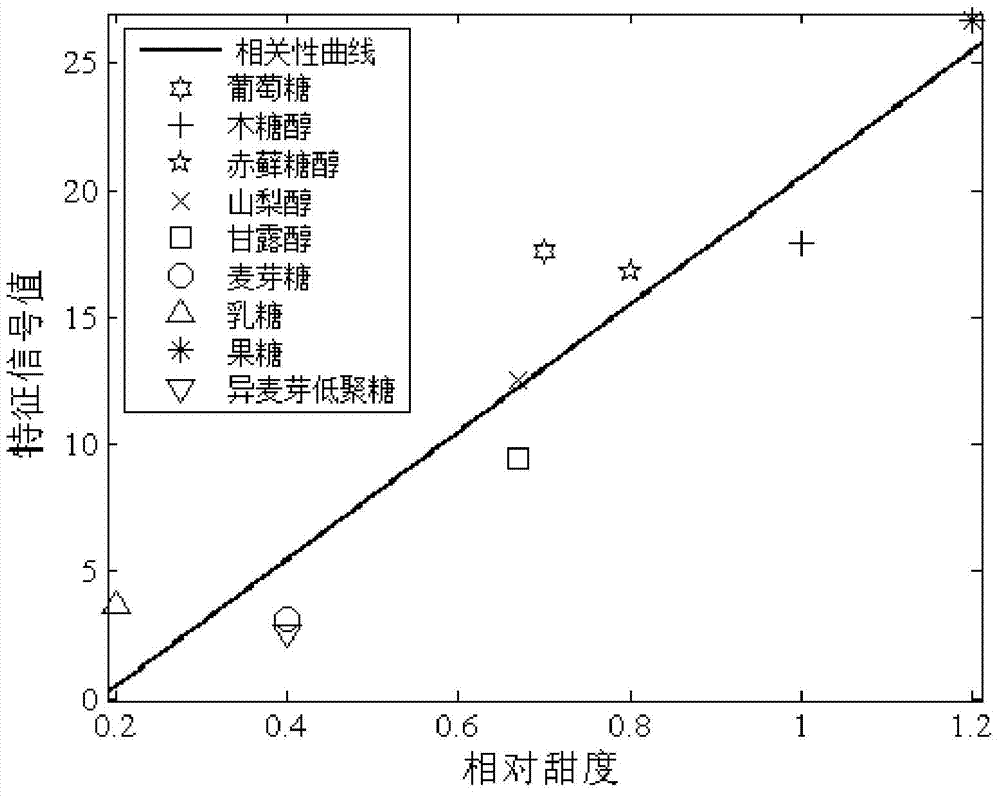

[0032] 5. Glucose, fructose, lactose, maltose, xylitol, erythritol, sorbitol, and mannitol were respectively prepared into aqueous solutions with sweetness of 0.2, 0.4, 0.6, 0.8, and 1.0 as standard products; the concentration of the preparation was 5 % sucrose solution as the sample to be tested. Take 1.5mL of each of the above samples and add them into 50mL of 1mol / L potassium hydroxide solution respectively to prepare the test s...

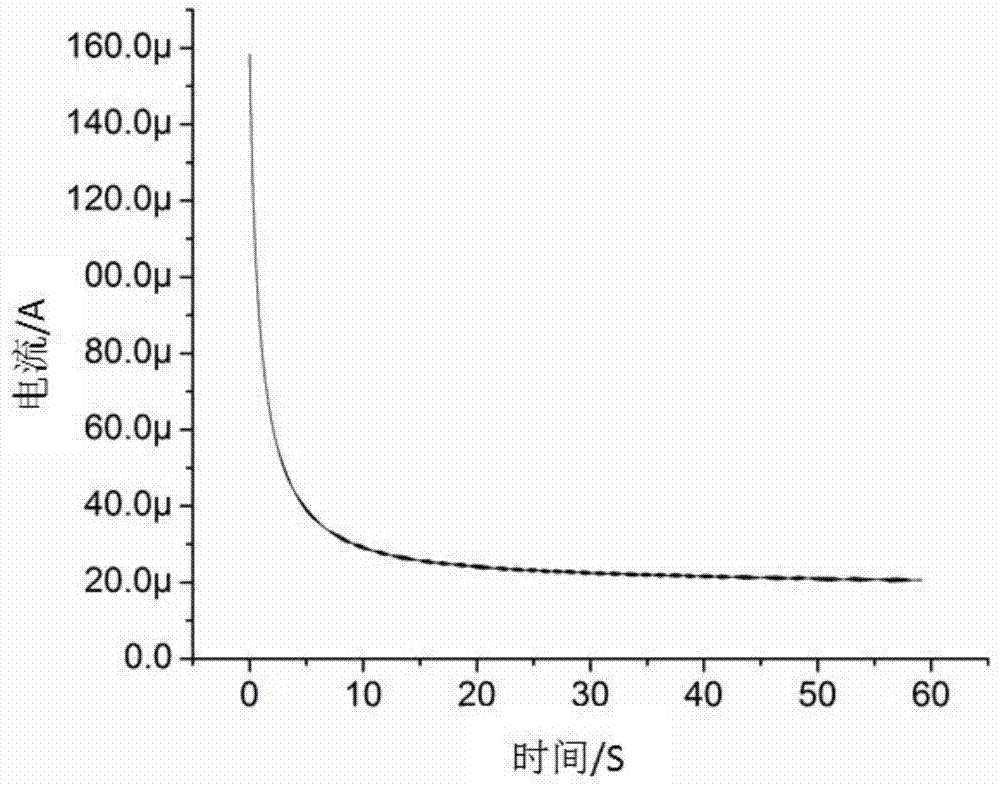

Embodiment 2

[0040] 1. Weigh graphite powder, liquid paraffin and nickel hydroxide in a ratio of 30:15:1 by weight, mix them evenly, and grind them to obtain a uniform paste.

[0041] 2. Pack the paste into a polytetrafluoroethylene casing, one end is flush with the bottom surface of the casing, and the other end is inserted into a copper rod.

[0042] 3. After the paste solidifies for 60 minutes, sand the flat end with fine sandpaper for 30 minutes to make a sweetness sensor.

[0043] 4. Prepare a potassium hydroxide solution with a concentration of 1mol / L.

[0044] 5. Glucose, fructose, lactose, maltose, xylitol, erythritol, sorbitol, and mannitol were respectively prepared into aqueous solutions with sweetness of 0.1, 0.3, 0.5, 0.7, and 0.9 as standard products; watermelon pulp Squeeze the juice, filter and take the clarified liquid as the sample to be tested. Take 1.5mL of each of the above samples and add them into 50mL of 1mol / L potassium hydroxide solution respectively to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com