Probiotic table salt and preparing method thereof

A technology for prebiotics and edible salt is applied in the field of prebiotic edible salt and its preparation to achieve the effects of preventing human sub-health diseases, promoting growth and reproduction, and maintaining stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

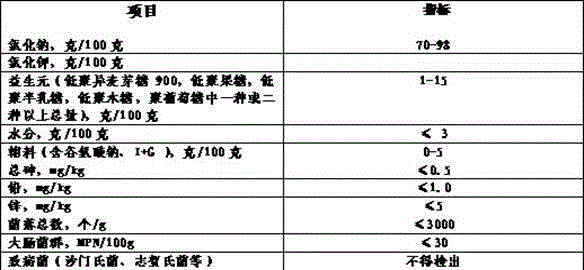

[0036] Combining the action mechanism of prebiotics and the amount of salt ingested by the human body, through experiments, the formula ratio range of the prebiotic edible salt described in this example is 70%-99.99% of sodium chloride and 0.01-30% of prebiotics.

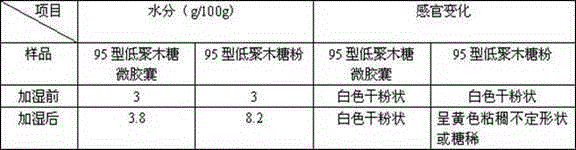

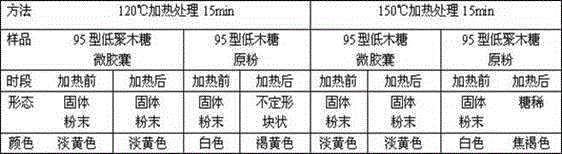

[0037] The prebiotic edible salt described in this embodiment can bind the intake of prebiotics with the intake of edible salt, thereby ensuring a stable and uniform intake of prebiotics. However, because prebiotics are easily absorbed Moisture makes it more difficult to store and transport table salt, especially when eating, after opening the sealed package, because the prebiotics mixed in the salt absorb moisture, it is easy to increase the water content of the prebiotics edible salt, and at least shorten the product During the shelf life, if the plate becomes agglomerated, it will be more difficult to use during cooking; in addition, because oligosaccharide prebiotics are not resistant to high temperatures, they w...

Embodiment 2

[0040] The first step, the colloidal embedding and microencapsulation process of prebiotics:

[0041] (1) Melt the prebiotics: Add the prebiotics into pure water at 45-60°C, stir and dissolve to make the concentration reach 20-60%.

[0042] (2) Add wall material and stir: add sodium carboxymethyl cellulose in an amount of 5-15%, stir and mix at 45-60°C for 30-60 minutes.

[0043] (3) Homogenization treatment: High-pressure homogenization treatment is carried out by a high-pressure homogenizer at a pressure of 25-60mpa, so that the prebiotics and wall materials form a full emulsion.

[0044] (4) Centrifugal spray drying: The uniform emulsion is dried by a centrifugal spray dryer at a drying temperature of 130-180°C and a drying time of 5-20 seconds to obtain prebiotic microcapsules with a moisture content of less than 3%.

[0045] (5) Granulation: The prebiotic microcapsules are made into 20-60 mesh granules with a dry granulator.

[0046] Step 2, Premix

[0047] The relativ...

specific Embodiment 3

[0055] Its finished product is white solid powder.

[0056] Embedding and microencapsulation process of isomaltooligosaccharide:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com