Sugar-free compound meal-replacement enzyme solution and preparation process thereof

An enzyme stock solution and enzyme technology, which is applied in the field of sugar-free compound meal replacement enzyme solution and its preparation technology, can solve the problems of not having the health care function of enzymes, loss of gastrointestinal tract, loss of interest in eating, etc., so as to increase the time of meal replacement, Extend satiety and reduce hunger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

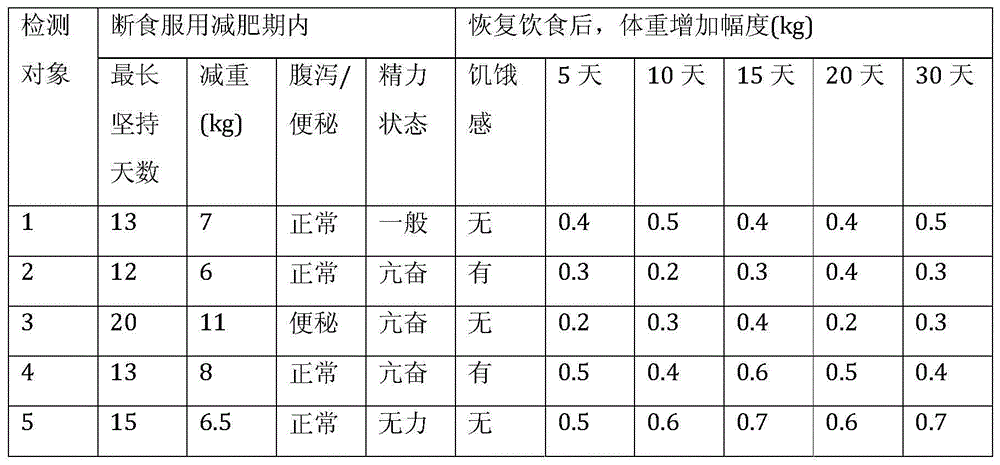

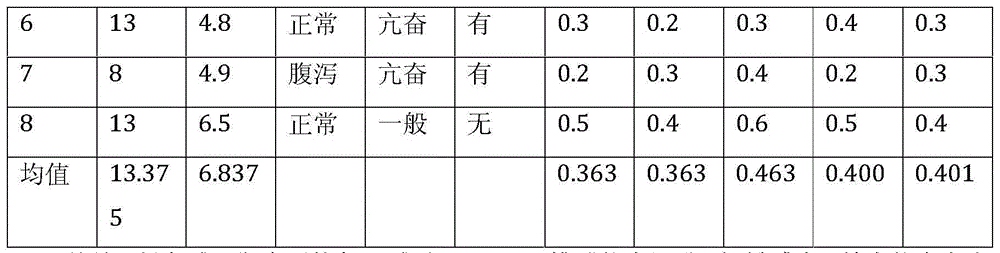

Image

Examples

Embodiment 1

[0033] The preparation method of the compound meal replacement enzyme liquid of this embodiment is as follows:

[0034] 1) Primary fermentation: mix and seal 100 parts of water, 1 part of Trichoderma reesei, 2 parts of Lactobacillus plantarum, 15 parts of glycerin, 5 parts of nicotinic acid, 10 parts of calcium hydrogen phosphate and 10 parts of bile salt, cultivate and activate and anaerobically Fermentation, the fermentation temperature is 38.5 ° C ~ 39 ° C, fermented for 10 days to obtain the enzyme stock solution;

[0035] Described Trichoderma reesei adopts commercially available Trichoderma reesei.

[0036] The plant Lactobacillus adopts commercially available Lactobacillus plantarum powder.

[0037] 2) Add additives to the original enzyme solution and carry out secondary fermentation at a temperature of 38.5°C to 40°C. After 15 to 30 days of fermentation, take the supernatant, which is the optimized enzyme solution.

[0038] The content of the additive is in parts by ...

Embodiment 2

[0046] The preparation method of the compound meal replacement enzyme liquid of this embodiment is as follows:

[0047]1) Primary fermentation: mix and seal 100 parts of water, 1 part of Trichoderma reesei, 2 parts of Lactobacillus plantarum, 5 parts of glycerin, 5 parts of nicotinic acid, 1 part of calcium hydrogen phosphate and 1 part of bile salt, cultivate and activate and anaerobically Fermentation, the fermentation temperature is 38.5 ° C ~ 39 ° C, fermented for 10 days to obtain the enzyme stock solution;

[0048] 2) Add additives to the original enzyme solution and carry out secondary fermentation at a temperature of 38.5°C to 40°C. After 15 to 30 days of fermentation, take the supernatant, which is the optimized enzyme solution.

[0049] The content of the additive is in parts by mass, and it consists of: 1 part of tartary buckwheat straw powder, 1 part of green tea powder, 1 part of horsetail powder, 1 part of white grass powder, 1 part of Artemisia annua powder, 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com