Method for preparing modified mesoporous alumina adsorbent for desulfurization and denitration

A mesoporous alumina, desulfurization and denitrification technology, applied in the field of adsorption, can solve the problems of removal that have not been reported, and achieve the effects of low cost, prolonged adsorption rate retention time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The preparation method of the modified mesoporous alumina adsorbent for desulfurization and denitrification is as follows:

[0025] Dissolve 2g of P123 in 40ml of absolute ethanol, stir well to dissolve; add 2.8ml of concentrated nitric acid, 0.76g of aluminum isopropoxide, 0.16g of Cu(NO 3 ) 3 ·3H 2 O, fully stirred for 12h; the obtained solution was evaporated to dryness in an oven at 40°C; the obtained solid was roasted in a muffle furnace, raised to 600°C at a rate of 1°C / min and kept at a constant temperature for 6h; the obtained modified mesoporous oxidation The aluminum is sieved to 40-60 mesh; put 2g of sieved modified mesoporous alumina (40-60 mesh) in a beaker, add 4ml of 0.1M potassium hydroxide solution to the beaker, and ultrasonically impregnate for 0.5h; then place Dry in an oven at 100°C for 15h; put the dried sample in a tube furnace under nitrogen protection, and roast at 400°C for 6h; a modified mesoporous alumina adsorbent for desulfuriz...

Embodiment 2

[0027] Example 2: The preparation method of the modified mesoporous alumina adsorbent for desulfurization and denitrification is as follows:

[0028] Dissolve 2g of P123 in 80ml of absolute ethanol, stir well to dissolve; add 3ml of concentrated nitric acid, 1g of aluminum isopropoxide, 0.2g of Cu(NO 3 ) 3 ·3H 2 O, continue to stir for 14h; evaporate the obtained solution to dryness in a 50°C oven; place the obtained solid in a muffle furnace for roasting, and raise it to 700°C at a constant temperature of 5h at a rate of 2°C / min; Alumina is sieved to 40-60 mesh; put 2g of sieved modified mesoporous alumina (40-60 mesh) in a beaker, add 5ml 0.2M potassium carbonate solution into the beaker, and ultrasonically impregnate for 0.75h; then Dry in an oven at 110°C for 13 hours; put the dried sample in a tube furnace under nitrogen protection, and roast at 500°C for 5 hours; prepare a modified mesoporous alumina adsorbent for desulfurization and denitrification;

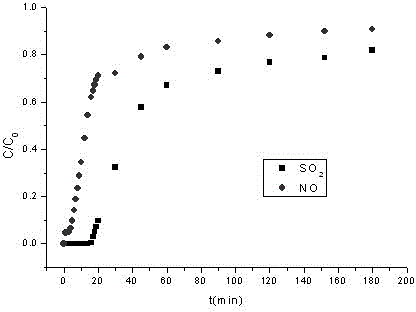

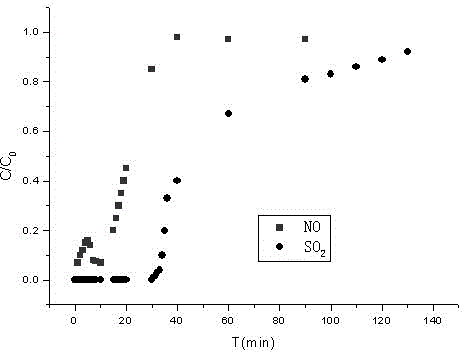

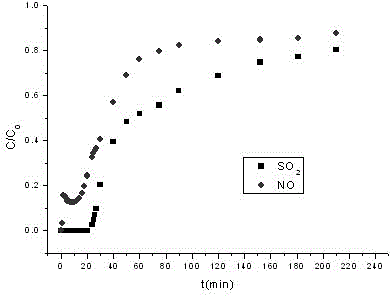

[0029] SO in th...

Embodiment 3

[0030] Example 3: The preparation method of the modified mesoporous alumina adsorbent for desulfurization and denitrification is as follows:

[0031] Dissolve 2g of P123 in 120ml of absolute ethanol, stir well to dissolve; add 3.2ml of concentrated hydrochloric acid, 1.18g of aluminum sec-butoxide, and 0.26g of copper chloride in sequence, and continue stirring for 15h; place the resulting solution in an oven at 60°C and evaporate to dryness ; The obtained solid was roasted in a muffle furnace, and the rate was raised to 800 degrees for 4 hours at a rate of 1.5 ° C / min; the obtained modified mesoporous alumina was sieved into 40-60 mesh; The mesoporous alumina (40-60 mesh) is placed in a beaker, and 6ml of 0.4M potassium chloride solution is added to the beaker, ultrasonically impregnated for 1h; then placed in an oven at 120°C for 12h; the dried sample is placed in a tube Under the protection of nitrogen in a type furnace, roast at 600°C for 4 hours; prepare a modified mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com