Fischer-Tropsch synthesis catalyst prepared by using composite sol as silicon source, and preparation method and application thereof

A technology of Fischer-Tropsch synthesis and composite sol, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. It can solve the problems of unsuitable iron-based catalysts for Fischer-Tropsch synthesis, and the final effect is not particularly significant. , to achieve excellent reaction stability, easy large-scale production, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

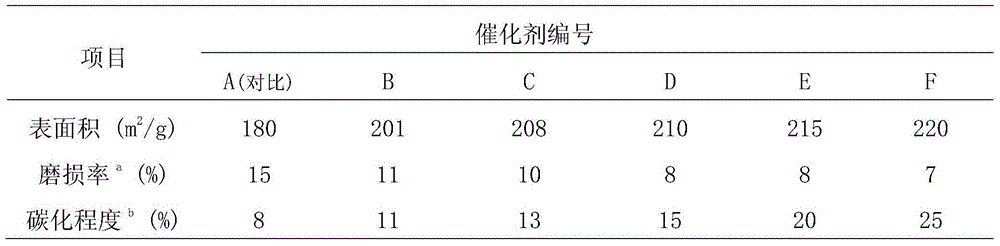

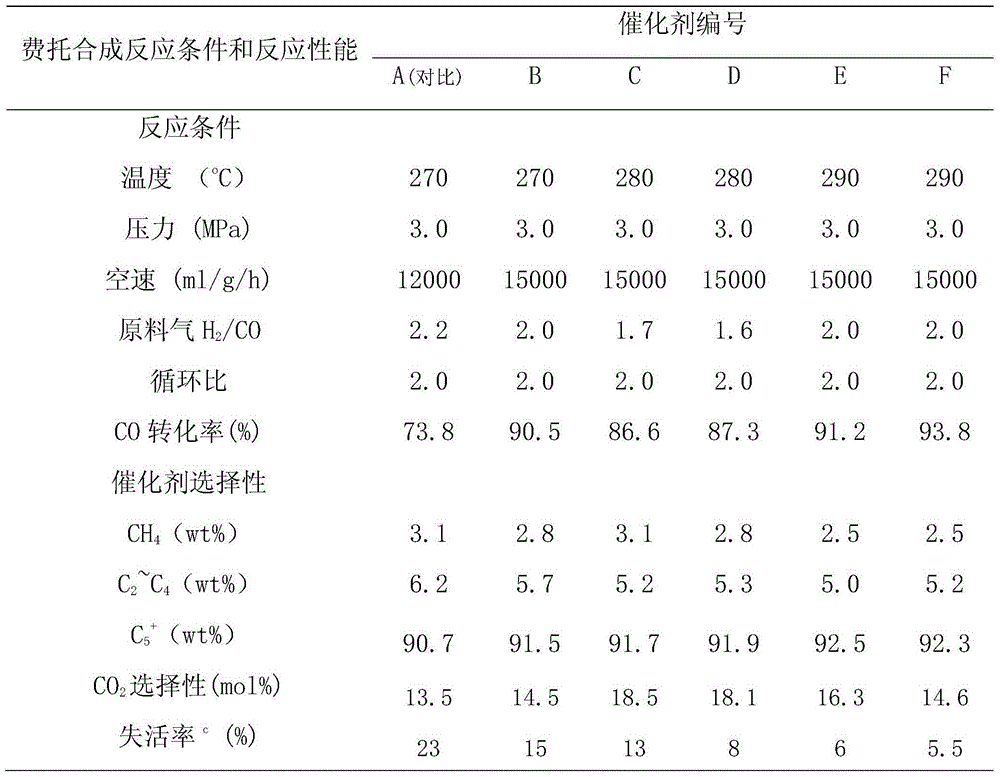

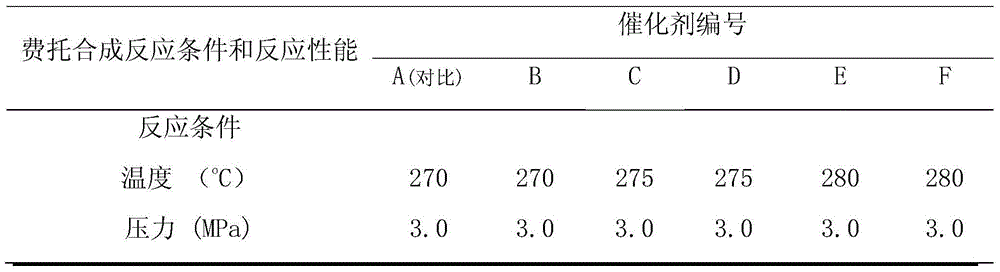

Examples

Embodiment 1

[0073] Take by weighing 212.6 kilograms of ferric nitrate nonahydrate, 5.7 kilograms of copper nitrate trihydrate, and 35.8 kilograms of 50wt% manganese nitrate solution and dissolve them in deionized water to prepare a 25.92wt% mixed nitrate solution for subsequent use. It consists of: Fe: Mn: Cu=100:19.6:5.3; 19.8 kg of sodium silicate was weighed to prepare a 10wt% sodium silicate solution, which was passed through 001×7 strongly acidic styrene system with a pH value of 6-7 at a flow rate of 25mL / min. Cation exchange resin column, the silicic acid solution is passed through 201×7 strong basic styrene-based anion exchange resin with a pH value of 7-8 under the condition of a flow rate of 25mL / min to obtain purified Silicic acid solution, take 7.8 kg of zirconium nitrate and prepare a 10wt% solution, add this solution to the above-mentioned purified silicic acid solution, stir and mix evenly, and age at 35°C for 10 hours to obtain a transparent composite sol, which consists of...

Embodiment 2

[0077] Take by weighing 212.6 kilograms of ferric nitrate nonahydrate, 5.7 kilograms of copper nitrate trihydrate, and 35.8 kilograms of 50wt% manganese nitrate solution and dissolve them in deionized water to prepare a 25.92wt% mixed nitrate solution for subsequent use. It consists of: Fe: Mn: Cu=100:19.6:5.3; Weigh 26.5 kg of sodium silicate to prepare a 10wt% sodium silicate solution, and pass it through the 001×7 strong acidic styrene system with a pH value of 6-7 at a flow rate of 25mL / min. Cation exchange resin column, 201×7 strongly basic styrene-based anion exchange resin column with a pH value of 7-8 to prepare a silicic acid solution with pH=4-5, weigh 3.2 kg of boric acid and prepare a 10wt% solution , add this solution to the above silicic acid solution, stir and mix evenly, and then age at 55°C for 50h to obtain a transparent composite sol, which consists of: SiO 2 : B=100:10; add the composite sol to the above mixed nitrate solution, and stir well; take the ammon...

Embodiment 3

[0079] Take by weighing 212.6 kilograms of ferric nitrate nonahydrate, 5.7 kilograms of copper nitrate trihydrate, and 35.8 kilograms of 50wt% manganese nitrate solution and dissolve them in deionized water to prepare a 25.92wt% mixed nitrate solution for subsequent use. It consists of: Fe: Mn: Cu=100:19.6:5.3; Weigh 1.96 kg of 200-mesh silicon powder, add it to 5.00wt% NaOH solution at 60°C and 100 L, stir and hydrolyze for 5 hours, and adjust the pH value to obtain a silica sol with pH=3-4 , Weigh 6.5 kg of cerium nitrate hexahydrate and prepare a 10wt% solution, add this solution to the above silica sol, stir and mix evenly, and age at 35°C for 10 hours to obtain a transparent composite sol, which consists of: SiO 2: Ce=100:50; Add the composite sol into the above-mentioned mixed nitrate solution, and stir well; take the ammonia solution with a concentration of 19.6wt%, preheat to 20°C, and keep stirring at 50°C and pH value Continuous co-precipitation at 9.0; aging for 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com