Preparation method of suspended graphene

A technology of graphene and high-temperature thermal decomposition method, which is applied in the field of semiconductors, can solve the problems of cumbersome preparation process and chemical pollution affecting the potential performance of suspended graphene, and achieve the effect of simple preparation method, strong effect and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of preparation method of circular suspended graphene, comprising:

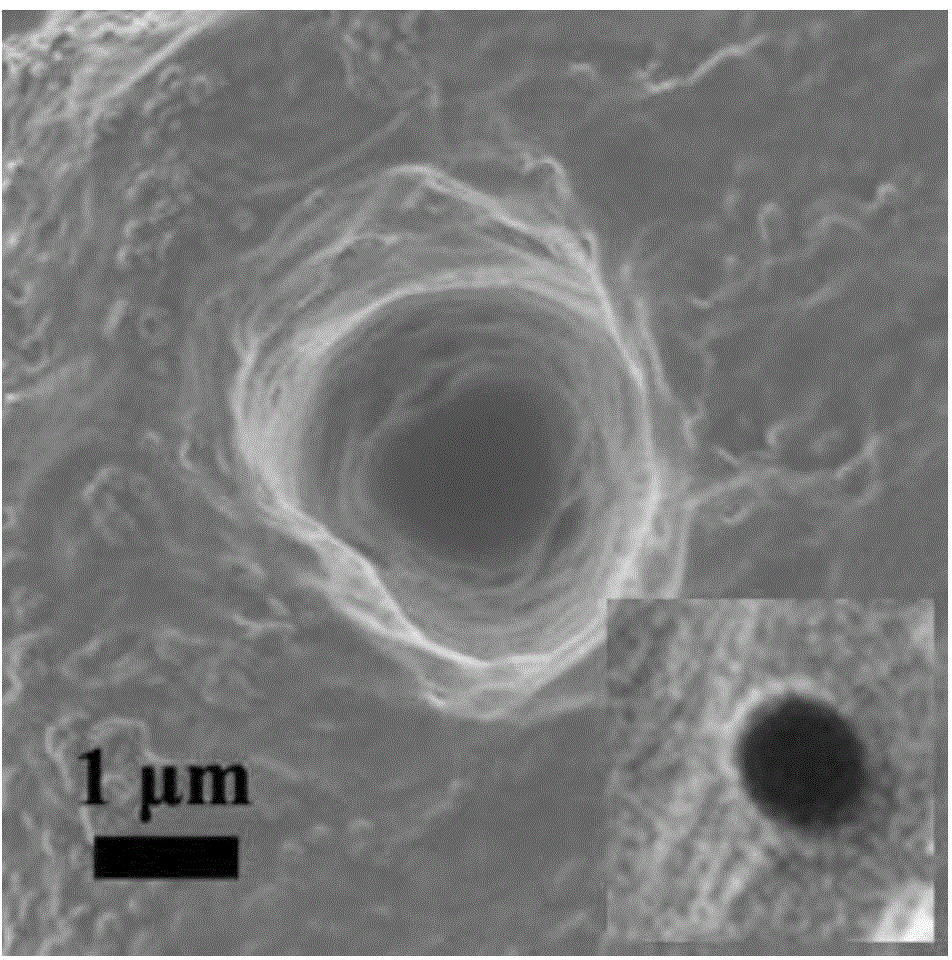

[0034] Step A: transfer a circle with a diameter of 1 μm to a 6H-silicon carbide single crystal substrate by photolithographic pattern transfer method, and then use reactive ion etching (RIE) to etch through the substrate ( >10μm) corresponding circular hole structure;

[0035] Step B: annealing in an atmosphere of 9 Pascal partial pressure of argon gas and 1 Pascal partial pressure of hydrogen gas to remove defects on the surface of the silicon carbide substrate;

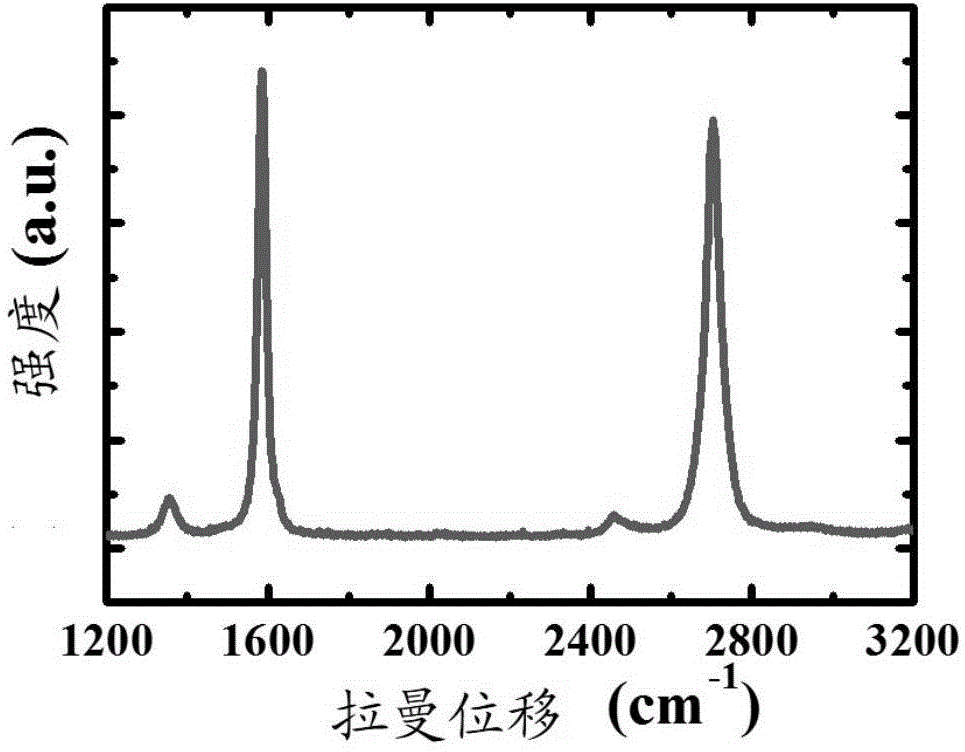

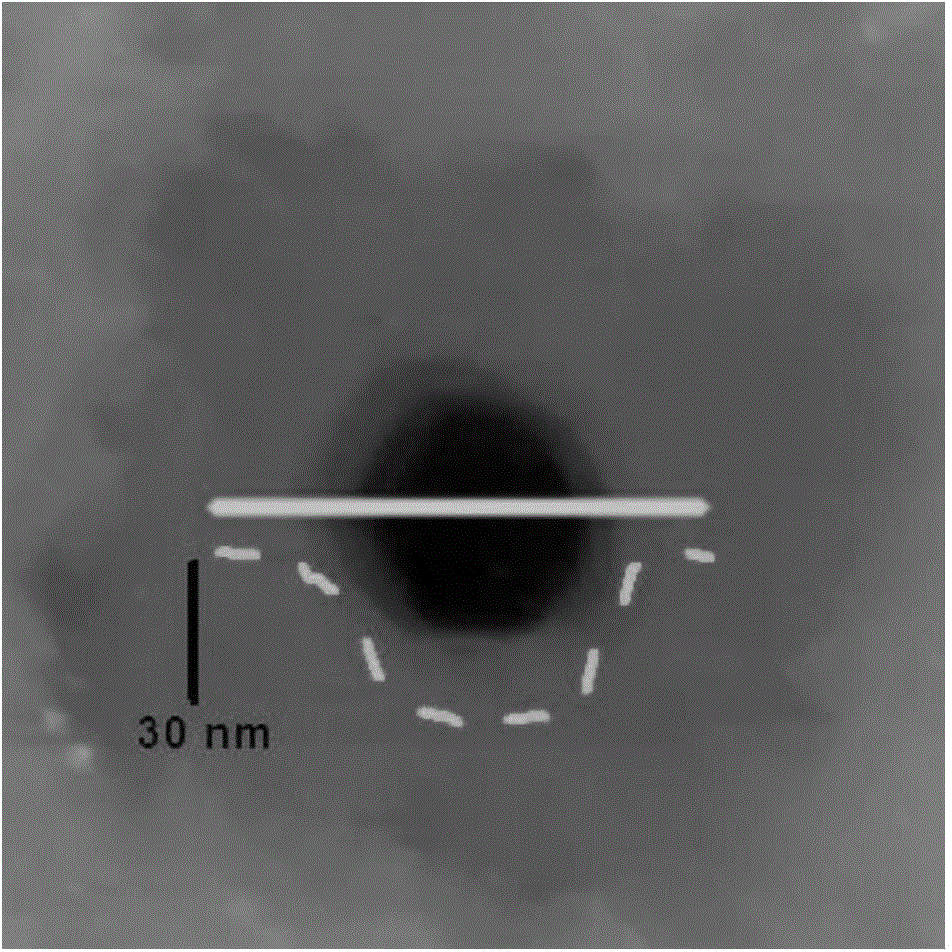

[0036] Step C: using a graphite crucible to provide an additional carbon source, in a carbon-rich environment, keep at 1300° C. for 30 minutes, and thermally decompose 6H-silicon carbide single crystal epitaxial growth of graphene at high temperature. In this process, first, a layer of graphene is grown on the silicon carbide substrate, and then the same carbon atom boundary as the circular hole struct...

Embodiment 2

[0041] This embodiment provides a method for preparing suspended graphene similar to the graphene six-membered ring structure, including:

[0042] Step A: Etch a graphic structure similar to the graphene six-membered ring structure on the 4H-silicon carbide single crystal substrate by focused ion beam etching, in which the diameter of the circular hole is about 2 μm, the line width is about 800 nm, and the depth of the structure is About 3μm;

[0043] Step B: using a graphite crucible to provide an additional carbon source, in a carbon-rich environment, keep at 1600° C. for 20 minutes, and thermally decompose 4H-silicon carbide single crystal epitaxial growth of graphene at high temperature. In this process, first, a layer of graphene is grown on the silicon carbide substrate, and then the same carbon atom boundary as the structure is formed at the edge of the graph structure obtained in step A. Second, excess carbon vapor in the environment combines with the carbon atoms at ...

Embodiment 3

[0046] The present embodiment provides a kind of preparation method of the suspended graphene of English letter " IOP " word, comprising:

[0047] Step A: transfer the English letter "IOP" with a line width of about 800nm to the 6H-silicon carbide single crystal substrate by photolithographic pattern transfer method, and then use reactive ion etching (RIE) on the 6H-silicon carbide single crystal substrate Corresponding structures were etched to a depth of about 3 μm.

[0048] Step B: annealing in an atmosphere of 9 Pascal partial pressure of argon and 1 Pascal partial pressure of hydrogen;

[0049] Step C: Preparing a carbon-rich environment by introducing methane gas, maintaining at 1300° C. for 20 minutes, thermally decomposing 6H-silicon carbide single crystal epitaxially growing graphene at high temperature. In this process, first, a layer of graphene is grown on the silicon carbide substrate, and then the same carbon atom boundary as the structure is formed at the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com