A kind of preparation method of zirconia

A technology of zirconium oxide and zirconium oxychloride, applied in zirconium oxide and other directions, can solve the problems of easy agglomeration of zirconium oxide, and achieve the effects of easy operation, overcoming serious agglomeration and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of zirconia provided by the invention comprises:

[0029] Add zirconium oxychloride and sodium hydroxide to ionic liquid-sodium trifluoromethanesulfonate for reaction, the reaction temperature is controlled at 260-300°C, the operating pressure is normal pressure, and the reaction time is 4-20 hours, preferably 6-20 hours. After 14 hours, after the reaction, the reaction product was washed with deionized water and centrifuged, and the obtained solid was treated at high temperature to obtain zirconia powder.

[0030] Wherein, the mass ratio of zirconium oxychloride to sodium hydroxide is 5-20:1. Sodium trifluoromethanesulfonate only acts as a solvent, and its consumption is determined according to actual production needs, and it is advisable to make the reaction go smoothly.

[0031] The particle size of the zirconia separated after the reaction is generally about 10nm. After high-temperature calcination, the physical indicators such as particle si...

Embodiment 1

[0039] Add 1 kg of sodium trifluoromethanesulfonate to the reactor, control the temperature of the oil bath at 300° C., and keep it warm for 2 hours, add 300 g of zirconium oxychloride and 30 g of sodium hydroxide, and keep it warm for 5 hours. The material in the reactor was poured into deionized water, centrifuged after stirring, and the solid was calcined at high temperature to control physical indicators such as particle size and specific surface area to obtain 107g of zirconia powder. Sodium trifluoromethanesulfonate is recovered from the mother liquor after recrystallization.

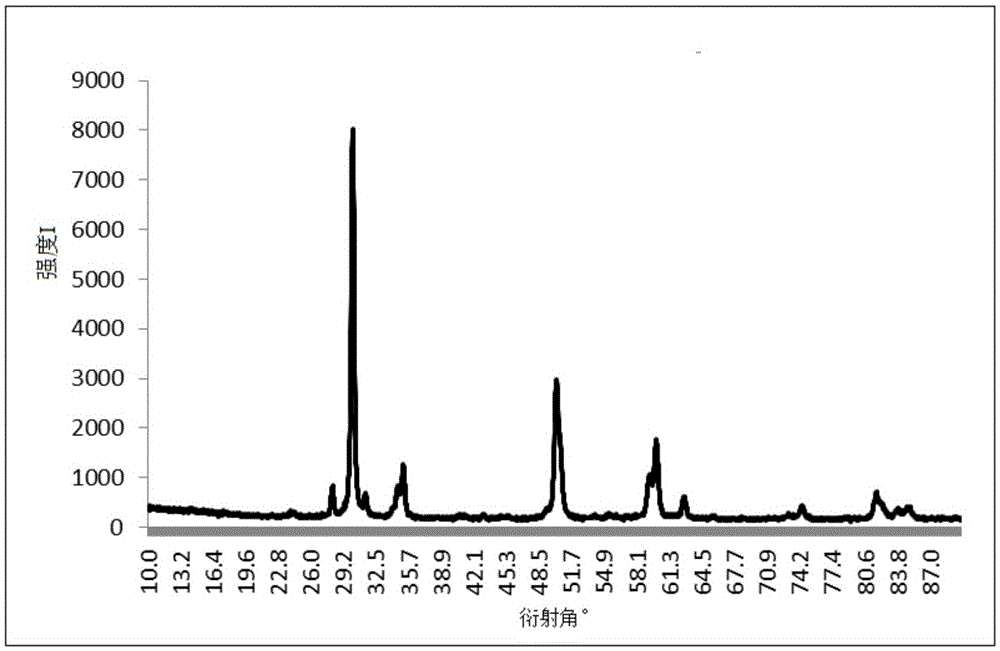

[0040] figure 1 The XRD spectrum of the product prepared in Example 1 is confirmed to be zirconia after comparing with the standard spectrum.

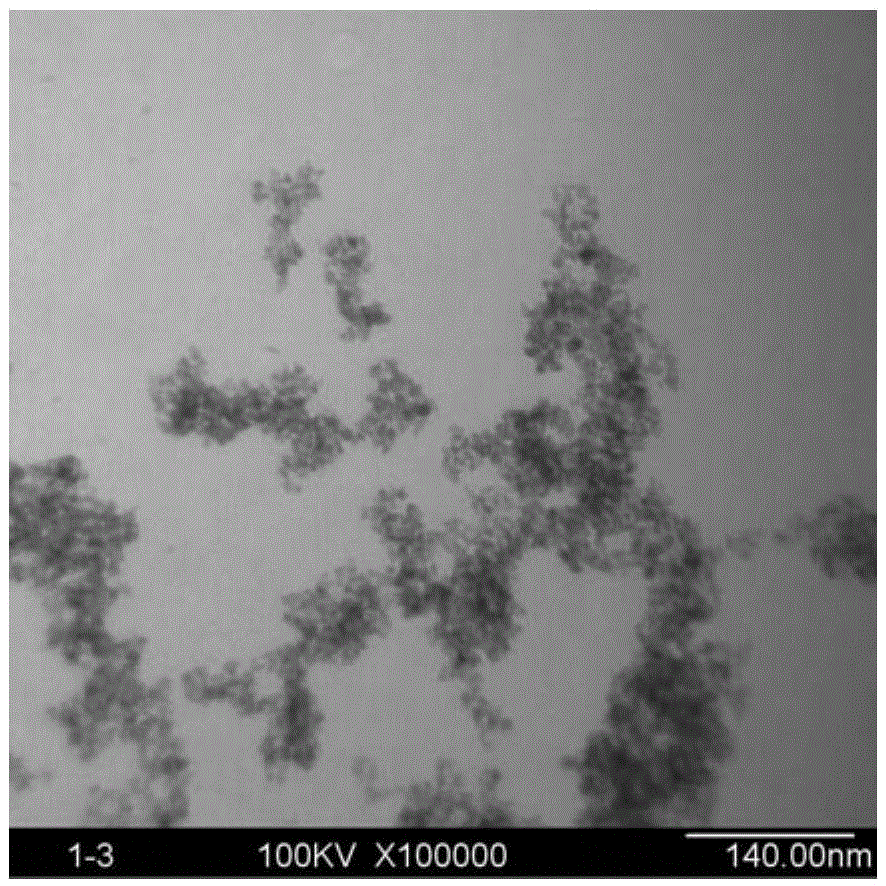

[0041] figure 2 Transmission electron micrograph (overall) of the product prepared for Example 1.

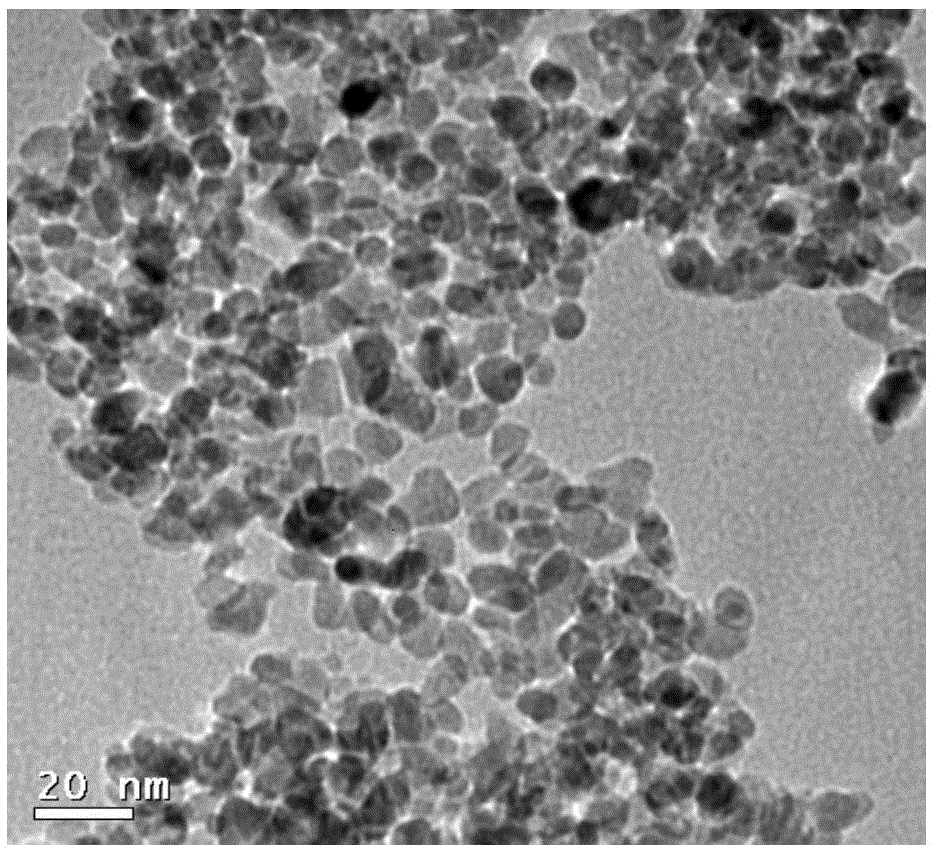

[0042] image 3 Transmission electron micrograph (microdomain) of the product prepared for Example 1.

[0043] From figure 2 and image 3 It can be...

Embodiment 2

[0045]Add 0.5kg of sodium trifluoromethanesulfonate to the reactor, control the temperature of the oil bath at 280°C, and keep it warm for 2 hours, then add 200g of zirconium oxychloride and 30g of sodium hydroxide, and keep it warm for 8 hours. Pour the contents of the reactor into deionized water, centrifuge after stirring, and calcine the solid at high temperature to control physical indicators such as particle size and specific surface area to obtain 71g of zirconia powder. Sodium trifluoromethanesulfonate is recovered from the mother liquor after recrystallization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com