Method for preparing lindera communis hemesl oil soap powder through spray drying of high tower

A technology of oil soap powder and drying, applied in the direction of preparation of detergent by chemical method, chemical instrument and method, soap detergent composition, etc., can solve the difficulty of increasing the cleaning of dust removal system, reduce the active ingredients of soap powder products, laundry soap The problem of low powder production efficiency is eliminated, and the effect of excellent washing effect, saving social pace and promising application prospect is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

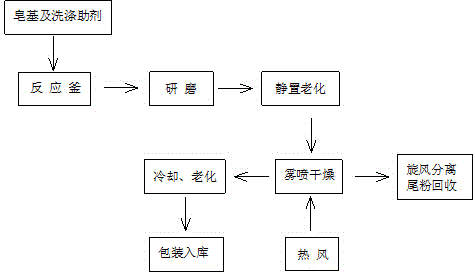

[0026] Such as figure 1 Shown, a kind of method utilizing high tower spray drying to prepare fragrant fruit oil soap powder, step comprises:

[0027] (1) 24.76 parts by weight of wild xiangguo oil was saponified with 7 parts by weight of liquid sodium hydroxide in a reaction pot equipped with a stirrer and open steam, and the wild natural xiangguo oil was removed by saponification and salting out twice. Impurities and pigments, and then through two alkali analysis and one finishing to obtain a pure soap base with a fatty acid content of more than 60%;

[0028] Wherein, the salting-out is to add brine to wash, and stand for 3 hours.

[0029] Wherein, each alkali analysis operation time is 3 hours, and the static time is 3 hours. During the preparation process, precautions should be taken: 1) The requirements for alkali analysis are gradually reduced to ensure the purity of the soap base; 2) After each alkali analysis, the soap particles are required to be boiled before turnin...

Embodiment 2

[0035] Such as figure 1 Shown, a kind of method utilizing high tower spray drying to prepare fragrant fruit oil soap powder, step comprises:

[0036] (1) 24.76 parts by weight of wild xiangguo oil was saponified with 7 parts by weight of liquid sodium hydroxide in a reaction pot equipped with a stirrer and open steam, and the wild natural xiangguo oil was removed by saponification and salting out twice. Impurities and pigments, and then through two alkali analysis and one finishing to obtain a pure soap base with a fatty acid content of more than 60%;

[0037] Wherein, salting-out is to add brine to wash, stand still for 3.5 hours.

[0038] Wherein, each alkali analysis operation time is 3.5 hours, and the static time is 3.5 hours.

[0039] Among them, the finishing operation time is 3.5 hours, and the rest time is 26 hours.

[0040] (2) Put 35 parts by weight of soap base into a reaction kettle containing a stirrer, add appropriate amount of water and 6.2 parts by weight o...

Embodiment 3

[0044] Such as figure 1 Shown, a kind of method utilizing high tower spray drying to prepare fragrant fruit oil soap powder, step comprises:

[0045](1) 24.76 parts by weight of wild xiangguo oil was saponified with 7 parts by weight of liquid sodium hydroxide in a reaction pot equipped with a stirrer and open steam, and the wild natural xiangguo oil was removed by saponification and salting out twice. Impurities and pigments, and then through two alkali analysis and one finishing to obtain a pure soap base with a fatty acid content of more than 60%;

[0046] Wherein, salting-out is to add brine to wash, stand still for 4 hours.

[0047] Wherein, each alkali analysis operation time is 4 hours, and the static time is 4 hours.

[0048] Among them, the finishing operation time is 4 hours, and the rest time is 28 hours.

[0049] (2) Put 35 parts by weight of soap base into a reaction kettle containing a stirrer, add appropriate amount of water and 6.2 parts by weight of liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com