A method for recovering anatase-type titanium-tungsten powder from waste vanadium-tungsten-titanium catalyst

An anatase-type catalyst technology, which is applied in the direction of improving process efficiency, can solve the problems that vanadium-tungsten-titanium catalyst cannot be used again, and the specific surface area is low, so as to shorten the holding time, reduce the roasting temperature, and have strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

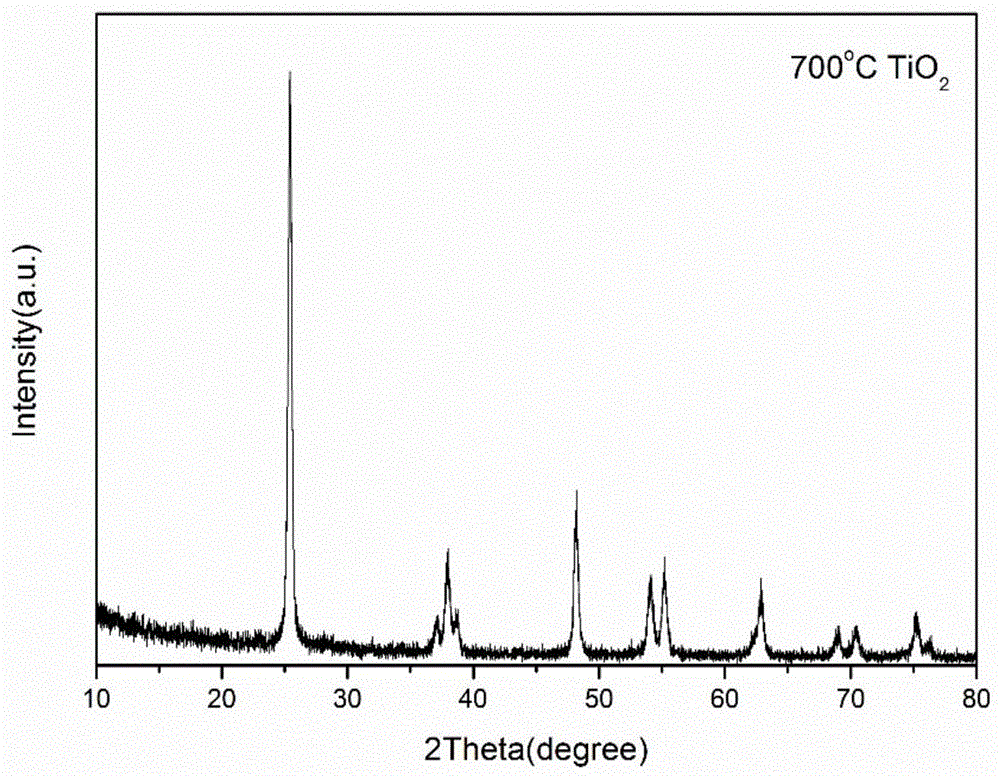

[0022] (1) Put the waste vanadium-tungsten-titanium catalyst into an ultrasonic oscillator, add a foaming agent at the same time for ultrasonic oscillation, use ultrasonic waves to remove dust and other substances adsorbed on the surface of the catalyst, and dry after cleaning; (2) After drying, The waste vanadium-tungsten-titanium catalyst is ground, and Na 2 CO 3 and NaClO 3 , mixed evenly and ground to 100-150 mesh, of which Na 2 CO 3 The mass ratio to the spent vanadium-tungsten-titanium catalyst is 1.5:1, NaClO 3 The mass ratio of the spent vanadium-tungsten-titanium catalyst is 1:100. (3) Put the mixed powder into a microwave roasting furnace, heat it to 700 °C with a heating rate of 100 °C / min, keep it warm for 30 minutes, and then cool it to room temperature with the furnace; (4) Microwave roasting and digestion to obtain The powder is ground and added to warm water at about 90°C, the mass ratio of powder to ...

Embodiment 2

[0027] This embodiment includes the following steps:

[0028] (1) Put the waste vanadium-tungsten-titanium catalyst into an ultrasonic oscillator, add a foaming agent at the same time for ultrasonic oscillation, use ultrasonic waves to remove dust and other substances adsorbed on the surface of the catalyst, and dry after cleaning; (2) After drying, The waste vanadium-tungsten-titanium catalyst is ground, and Na 2 CO 3and NaClO 3 , mix well and grind to 100-150 mesh. where Na 2 CO 3 The mass ratio with spent vanadium tungsten titanium catalyst is 1.3:1, NaClO 3 The mass ratio of spent vanadium-tungsten-titanium catalyst is 1:100. (3) Put the mixed powder into a microwave roasting furnace, heat it up to 600°C with a microwave at a heating rate of 100°C / min, keep it warm for 30 minutes, and then cool it down to room temperature with the furnace. (4) Grind the powder obtained by microwave roasting and digestion, add it into warm water at about 90°C, the mass ratio of powde...

Embodiment 3

[0033] This embodiment includes the following steps:

[0034] (1) Put the waste vanadium-tungsten-titanium catalyst into an ultrasonic oscillator, add a foaming agent at the same time for ultrasonic oscillation, use ultrasonic waves to remove dust and other substances adsorbed on the surface of the catalyst, and dry after cleaning; (2) After drying, The waste vanadium-tungsten-titanium catalyst is ground, and Na 2 CO 3 and NaClO 3 , mix well and grind to 100-150 mesh. where Na 2 CO 3 The mass ratio to the spent vanadium-tungsten-titanium catalyst is 1.5:1, NaClO 3 The mass ratio of the spent vanadium-tungsten-titanium catalyst is 5:100. (3) Put the mixed powder into a microwave roasting furnace, heat it up to 500°C with a microwave at a heating rate of 100°C / min, keep it warm for 30 minutes, and then cool it down to room temperature with the furnace. (4) Grind the powder obtained by microwave roasting and digestion, add it into warm water at about 90°C, the mass ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com