Preparation method of modified ternary cathode material

A positive electrode material and modification technology, which is applied in the field of preparation of modified ternary positive electrode materials, can solve the problems of destroying the interface structure, poor high-temperature cycle performance of ternary positive electrode materials, and capacity fading, so as to achieve uniform coating coating and benefit electronics The effect of transmitting and increasing the discharge power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

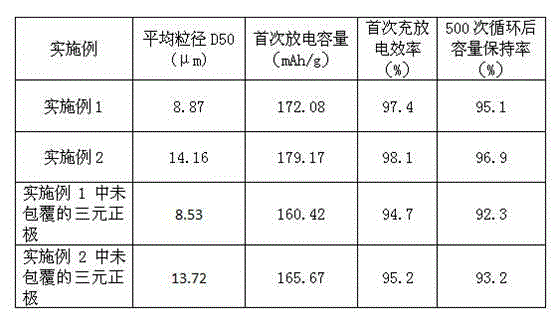

Embodiment 1

[0026] Take 5g of ternary positive electrode material, the average particle size D50 is 8.53 μm, and perform electroless nickel plating treatment. The process of electroless nickel plating is:

[0027] 1. Add the above-mentioned ternary cathode material into the alcohol aqueous solution with a volume ratio of alcohol to water of 1:1 and a total volume of 1L. The temperature is 25° C., the stirring speed is 200 rpm, and the ultrasonic vibration is performed at a frequency of 30 kHz for 5 min.

[0028] The ternary cathode material was centrifuged and washed several times with deionized water.

[0029] 2. Add the cleaned ternary positive electrode material into a solution with the ingredients of stannous chloride (SnCl2 2H2O) 4g / L, 37% HCl 4mL / L, OP-101mL / L, and the solvent is deionized water with a volume of 1L middle. The temperature is 25°C, the stirring speed is 200 revolutions per minute, and the time is 2 minutes. The ternary cathode material was centrifuged and washed w...

Embodiment 2

[0035]Take 20g of ternary positive electrode material, the average particle size D50 is 13.72 μm, and perform electroless nickel plating treatment. The process of electroless nickel plating is:

[0036] 1. Add the above-mentioned ternary cathode material into an alcohol-water solution with a volume ratio of alcohol to water of 1:2 and a total volume of 1L. The temperature is 25° C., the stirring speed is 200 rpm, and the ultrasonic vibration is performed at a frequency of 35 kHz for 8 min. The ternary was centrifuged and washed several times with deionized water.

[0037] 2. Add the cleaned ternary positive electrode material with stannous chloride (SnCl2 2H2O) 7g / L, 37% HCl 5mL / L, 0.5mL / L each of sucrose ester and OP-10, and the solvent is deionized water , in a solution with a volume of 1 L. The temperature is 25° C., the stirring speed is 400 revolutions per minute, and the time is 2 minutes. The ternary cathode material was centrifuged and washed with deionized water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com