A kind of regeneration method of denitrification catalyst

A denitration catalyst and catalyst technology, which are applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of reduced mechanical strength of catalysts, reduced denitration efficiency, etc., and achieve low cost, short working cycle, and increased specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

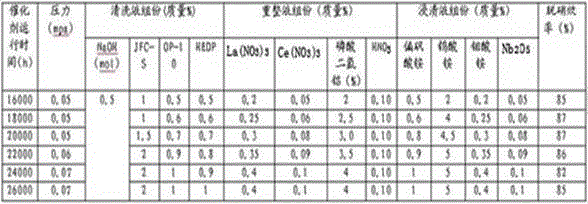

Embodiment 1

[0026] For the denitrification catalyst running for 16000h, the negative pressure used in step (1) is 0.05MPa, and the ash on the surface of the catalyst is vacuumed and cleaned with a brush with a diameter of 3-5mm. Step (2) Use a cleaning solution to clean the catalyst surface and pores. The volume ratio of the cleaning solution to the catalyst volume is 7:1. The cleaning solution is composed of 0.5 mole NaOH, 1% penetrant JFC-S, and 0.5% emulsifier OP -10, 0.5% metal chelating agent HEDP, ultrasonic power of 6KW, frequency of 40HZ, cleaning temperature of 30°C, cleaning time of 30min, and drying temperature of 90°C after cleaning. Step (3) impregnate the catalyst with a nitric acid solution containing 0.1 mole of 0.2% lanthanum nitrate, 0.05% cerium nitrate, and 2% aluminum dihydrogen phosphate. The impregnation temperature is 30°C, and the impregnation time is 3 hours. Calcined for 4 hours. Step (4) Use 2% oxalic acid solution to dissolve 0.5% ammonium metavanadate, 2% am...

Embodiment 2

[0028] For the denitrification catalyst running for 18,000 hours, while repeating Example 1, the difference is that in step (2), the surface and pores of the catalyst are cleaned with an ultrasonic cleaning solution. The volume ratio of the cleaning solution to the catalyst volume is 7:1, and the cleaning solution consists of 0.5 mole NaOH, 1% penetrant JFC-S, 0.6% emulsifier OP-10, 0.6% metal chelating agent HEDP, ultrasonic power 6KW, frequency 40HZ, cleaning temperature 30°C, cleaning time 30min, post-baking Dry. Step (3) impregnate the catalyst with a nitric acid solution containing 0.1 mole of 0.25% lanthanum nitrate, 0.06% cerium nitrate, and 2.5% aluminum dihydrogen phosphate. The impregnation temperature is 30°C, and the impregnation time is 3 hours. °C for 4 hours. Step (4) Use 2% oxalic acid solution to dissolve 0.6% ammonium metavanadate, 4% ammonium tungstate, 0.25% ammonium molybdate, and 0.06% niobium pentoxide solution. After immersing at 30°C for 3 hours, and...

Embodiment 3

[0030] For the denitrification catalyst running for 20,000 hours, while repeating Example 2, the difference is that in step (2), the surface and pores of the catalyst are cleaned with a cleaning solution. The volume ratio of the cleaning solution to the catalyst volume is 7:1, and the cleaning solution is composed of 0.5 mole NaOH, 1.5% penetrant JFC-S, 0.7% emulsifier OP-10, 0.7% metal chelating agent HEDP, ultrasonic power 6KW, frequency 40HZ, cleaning temperature 30°C, cleaning time 30min, and post-drying . Step (3) Use 0.1 mole nitric acid solution containing 0.30% lanthanum nitrate, 0.08% cerium nitrate, and 3% aluminum dihydrogen phosphate to impregnate the catalyst. The impregnation temperature is 30°C, and the impregnation time is 3 hours. °C for 4 hours. Step (4) Use 2.5% oxalic acid solution to dissolve 0.8% ammonium metavanadate, 4.5% ammonium tungstate, 0.30% ammonium molybdate, and 0.08% niobium pentoxide solution. 3 hours, immersion temperature 30 ℃, and then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com