Cobalt-manganese-based spinel nano material as well as preparation method and application thereof

A technology of nanomaterials and spinel, which is applied in the field of preparation of spinel nanomaterials, can solve problems such as the inability to independently control the structure and chemical composition of cobalt manganese spinel, achieve rich defect active sites, low energy consumption, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of cobalt-manganese spinel nanomaterial, wherein the cobalt-manganese spinel nanomaterial is cubic phase CoMn 2 O 4 Nanoparticles, with an average particle size of 11nm and a molar ratio of Co to Mn of 1:2.12, including the following steps;

[0028] 1) Add 4mL of 14mol / L ammonia droplets to 5mL of 0.2mol / L Co(NO 3 ) 2 In the solution, stir for 120 min at room temperature under an air atmosphere to obtain a mixed solution a;

[0029] 2) Under magnetic stirring, add dropwise 10 mL of 0.2mol / L Mn(NO 3 ) 2 After the addition of the solution, continue to stir for 120 minutes to obtain a mixed solution b;

[0030] 3) Raise the temperature of the above-mentioned mixed liquid b to 180°C and keep it for 40 minutes, and then evaporate the solvent to completely decompose and crystallize the metal salts a and b, and prepare the cubic phase CoMn of the cobalt-manganese spinel nanomaterial 2 O 4 .

Embodiment 2

[0032] A method for preparing cobalt-manganese spinel nanomaterials, wherein the cobalt-manganese spinel nanomaterials are cubic phase Co 1.5 Mn 1.5 O 4 Nanoparticles, with an average particle size of 10nm, and a molar ratio of Co to Mn of 1.02:1. The preparation steps are basically the same as those in Example 1), except that: in step 1) Co(NO 3 ) 2 The concentration of the solution is 0.3mol / L, in step 2) Mn(NO 3 ) 2 The concentration of the solution is 0.15 mol / L.

Embodiment 3

[0034] A method for preparing cobalt-manganese spinel nanomaterials, wherein the cobalt-manganese spinel nanomaterials are cubic phase Co 2 MnO 4 Nanoparticles, with an average particle size of 9nm, and a molar ratio of Co to Mn of 2.03:1, and the preparation steps are basically the same as in Example 1), except that: in step 1) Co(NO 3 ) 2 The concentration of the solution is 0.4mol / L, in step 2) Mn(NO 3 ) 2 The concentration of the solution is 0.1 mol / L.

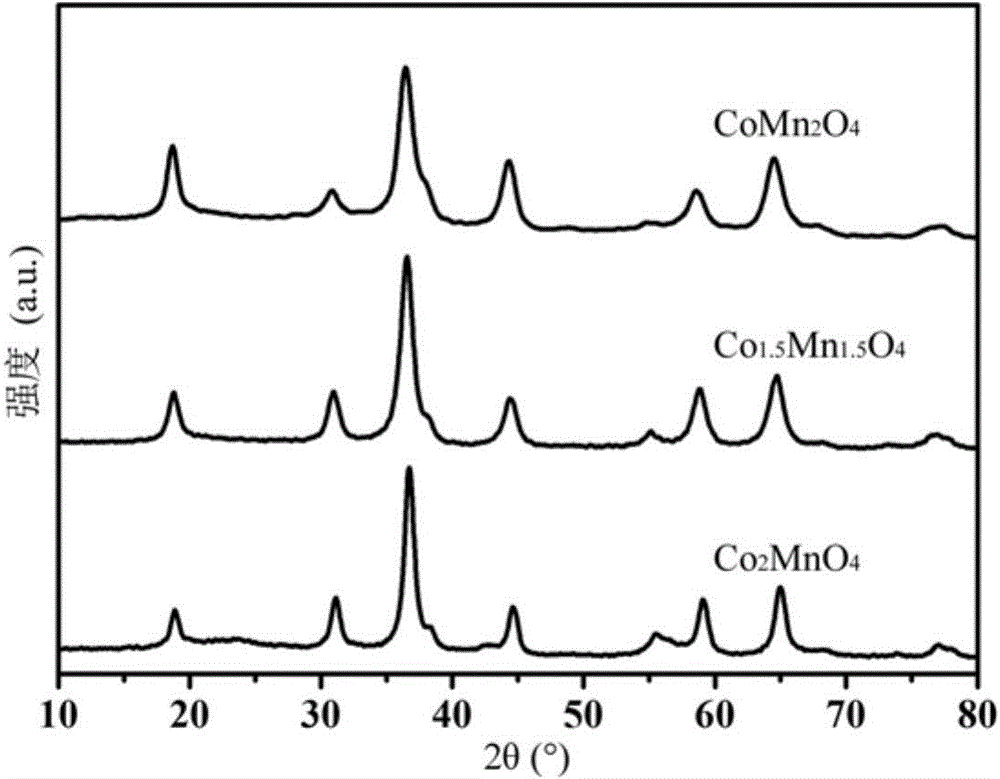

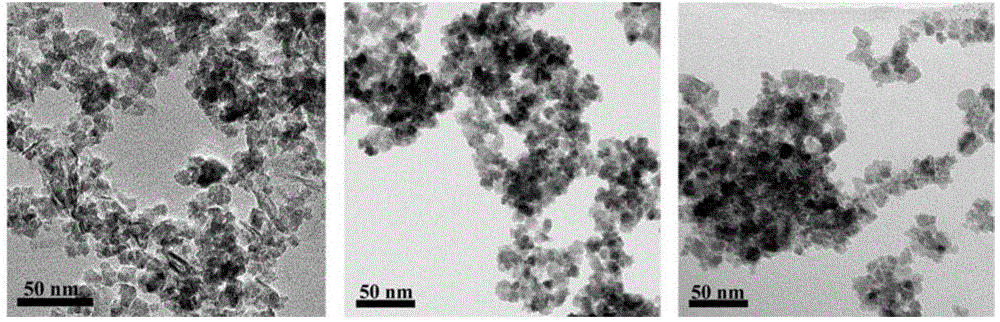

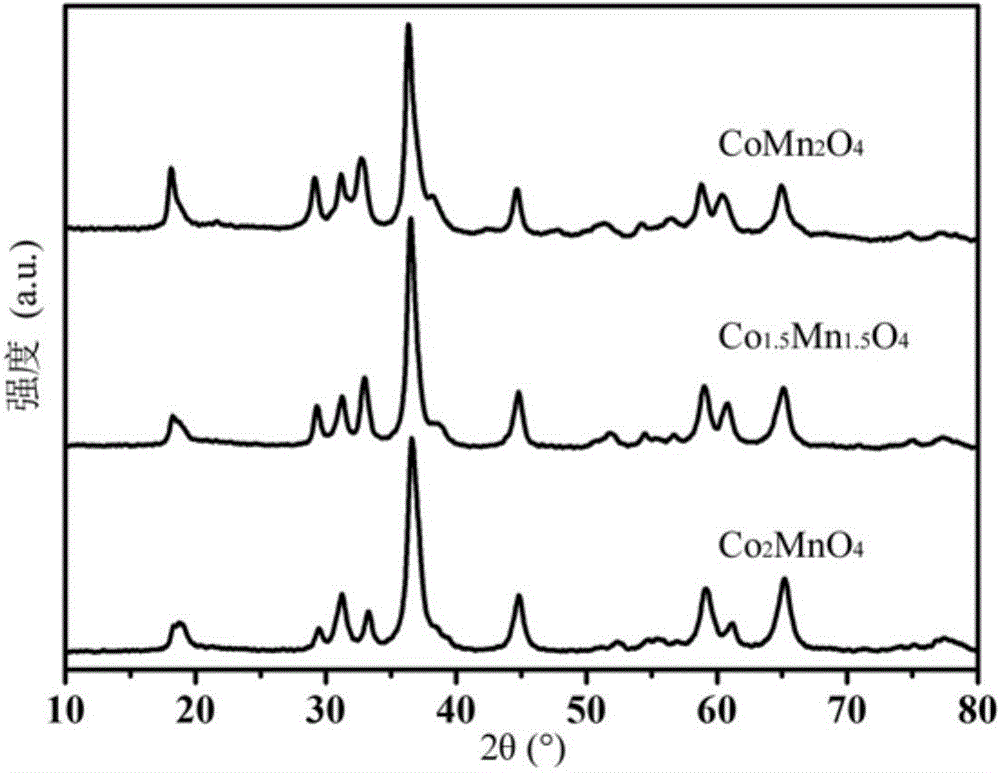

[0035] Co prepared in the above examples 1), 2), and 3) 3-x Mn x O 4 The XRD pattern of the nanoparticles is as figure 1 As shown, the cubic crystal form, the peak position and intensity are consistent with JCPDS standard card No.23-1237, the unit cell parameters calculated from the characteristic peaks in the spectrum are smaller than the standard value, indicating that it contains rich metal ions defect. The broadening of the diffraction peak is caused by the product being ultra-fine nanocrystalline grains. Transmission ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com