Use of solid acid catalyst in synthesis of isobornyl acrylate

A technology of isobornyl acrylate and solid acid catalyst, which is applied in the preparation of organic compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low yield of isobornyl acrylate, The problems of dissolution and poor selectivity of solid acid catalysts can achieve the effect of simple and easy synthesis method, good recycling performance and strong acidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

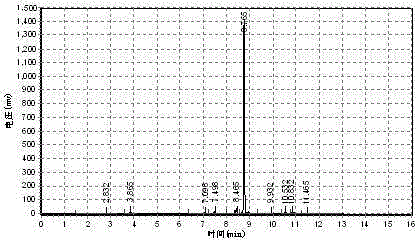

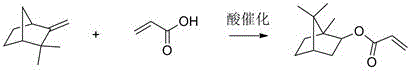

[0021] In order to overcome the problems that side reactions easily occur in the existing solid acid catalyzed synthesis of isobornyl acrylate, the yield of isobornyl acrylate is low, the selectivity is poor, and the solid acid catalyst is prone to partial dissolution, swelling and fragmentation. This embodiment provides a kind of like figure 1 The application of the solid acid catalyst shown in the synthesis of isobornyl acrylate, the solid acid catalyst is 30 ~ 90 at the reaction temperature o Catalyzing the reaction of acrylic acid and amphene for 2 to 10 hours under C conditions to prepare isobornyl acrylate, the molar ratio of acrylic acid and amphene is 1.2:1 to 3:1, and the mass of the solid acid catalyst is 1% to 25% of the mass of amphene.

[0022] Among them, the solid acid catalyst is mixed and dissolved with metal halide and water at a mass ratio of 1:5 to 1:100, and then the metal halide solution is adjusted to pH = 8 to 10 with lye with a concentration of 5 to 20...

Embodiment 2

[0025] Weigh 3.506 g SnCl 4 ·5H 2 O, 13.280 g TiCl 4 , 2.703 g FeCl 3 ·6H 2 O, 2.252 g ZnBr 2 (The molar percentage of the metal is 10%:70%:10%:10%), dissolve it in 500 mL of water, stir well to dissolve, and add 10% ammonia water to the solution to adjust the pH to 8. After standing and aging the neutralized solution for 20 hours, it was washed 5 times with deionized water. The washed solid is placed in an oven at 120 o C drying for 20 hours. The dried solid powder is fully ground and passed through a 200-mesh sieve, and a certain amount of ammonium phosphate is weighed (the mass ratio of its mass to the solid powder mass is 1:4), and it is fully mixed with the ground solid powder after sieving. Put the mixed solid powder in the muffle furnace, 450 o C was calcined for 5 h to obtain a solid acid catalyst.

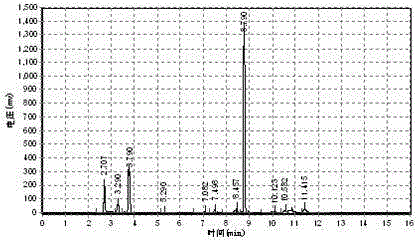

[0026] Weigh 21.618 g of acrylic acid, 27.246 g of amphene (the molar ratio of acrylic acid to amphene is 1.5:1), 4.087 g of synthesized solid acid catalyst and 2...

Embodiment 3

[0030] Weigh 5.25 g SnCl 4 ·5H 2 O, 18.656 g ZrCl 4 , 1.352 g FeCl 3 ·6H 2 O (the molar percentage of metal is 15%:80%:5%), dissolve it in 1000 mL water, stir well to dissolve, add 20% sodium hydroxide to the solution to adjust the pH to 10; neutralize After the solution was left to age for 30 hours, it was washed 10 times with deionized water; the washed solid was placed in an oven for 120 oC Dry for 30 hours; the dried solid powder is fully ground and passed through a 100-mesh sieve, and a certain amount of ammonium sulfate and ammonium bisulfate mixture is weighed. The mass ratio of the mixture to the solid powder is 1:20. The solid sieved powder is fully mixed; the mixed solid powder is placed in a muffle furnace, 600 o C was calcined for 15 h to obtain a solid acid catalyst.

[0031] Weigh 21.618 g of acrylic acid, 13.623 g of amphene (the molar ratio of acrylic acid to amphene is 3:1), 0.1362 g of synthesized solid acid catalyst and 2 g of hydroquinone inhibitor, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com