CoM1M2-based hydrotalcite-like precursor mother liquor, catalyst preparation method, and applications of catalyst

A technology of hydrotalcite and precursor, which is applied in the field of industrial synthesis of mixed alcohol preparation, can solve the problems of difficult control of catalyst process, unsatisfactory catalyst selectivity, yield and stability, etc., and achieves low deactivation and low carbon selectivity. The effect of high and high alcohol selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

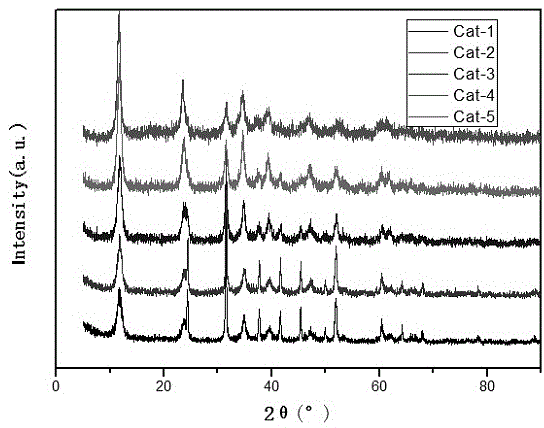

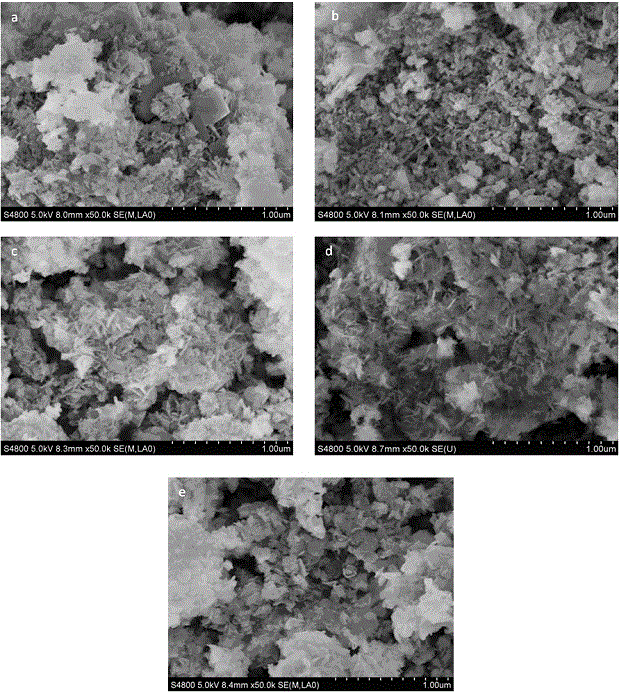

[0026] In this example, see figure 1 , figure 2 (a) and Table 1, a method using CoM 1 m 2 Preparation of CoM from base hydrotalcite precursor mother liquor 1 m 2 The method of base catalyst, comprises the steps:

[0027] a. According to n(Co):n(Mn):n(Al)=1:1:1 (molar ratio), prepare nitrate with a total metal ion concentration of 1.0mol / L [Co(NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 , Al(NO 3 ) 3 9H 2 O] solution, press n(NaOH):n(Na 2 CO 3 ) = 1 (molar ratio) to prepare NaOH and Na 2 CO 3 The total concentration of the mixed lye is 1.0mol / L. Under the condition of room temperature and sufficient stirring, the co-current co-precipitation reaction is carried out, and the pH value of the precipitation mother liquor is kept in the range of 9 ± 0.2;

[0028] b. After the precipitation is over, continue to stir in a constant temperature oil bath at 60°C for 12 hours, then cool to room temperature and filter with suction, wash the filter cake with deionized water until the filt...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, especially in that:

[0036] In this example, see figure 1 , figure 2 (b) and Table 1, a method using CoM 1 m 2 Preparation of CoM from base hydrotalcite precursor mother liquor 1 m 2 The method of base catalyst, comprises the steps:

[0037] a. According to n(Co):n(Mn):n(Mg):n(Al)=1:1:1:1 (molar ratio), prepare nitrate with a total metal ion concentration of 1.0mol / L [Co( NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O] solution, press n(NaOH):n(NaOH 2 CO 3 ) = 2 (molar ratio) to prepare NaOH and Na 2 CO 3 The total concentration of the mixed lye is 2mol / L, at room temperature and under the condition of sufficient stirring, carry out co-current co-precipitation reaction, and the pH value of the precipitation mother liquor is kept in the range of 9 ± 0.2;

[0038] b. This step is identical with embodiment one;

[0039] c. This step is identical with embodiment one;

[...

Embodiment 3

[0044] This embodiment is basically the same as the previous embodiment, and the special features are:

[0045] In this example, see figure 1 , figure 2 (c) and Table 1, a method using CoM 1 m 2 Preparation of CoM from base hydrotalcite precursor mother liquor 1 m 2 The method of base catalyst, comprises the steps:

[0046] a. According to n (Co): n (Mn): n (Zr): n (Al) = 1:1:1:1 (molar ratio) to prepare nitrate with a total metal ion concentration of 1.0mol / L [Co( NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 , Zr(NO 3 ) 4 ·5H 2 O, Al(NO 3 ) 3 9H 2 O] solution, press n(NaOH):n(NaOH 2 CO 3 ) = 2 (molar ratio) to prepare NaOH and Na 2 CO 3 The total concentration of the mixed lye is 2mol / L, at room temperature and under the condition of sufficient stirring, carry out co-current co-precipitation reaction, and the pH value of the precipitation mother liquor is kept in the range of 9 ± 0.2;

[0047] b. This step is identical with embodiment one;

[0048] c. This step is ide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com