Quasi-zero-polar-distance electrolytic tank for water treatment

An electrolytic cell and water treatment technology, which is applied in the field of electrochemistry, can solve the problems of decreased ion exchange capacity, increased tank pressure, and inability to reduce energy consumption, etc., to achieve reduced energy consumption, reduced tank pressure, and reduced floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Treatment of landfill leachate in a certain landfill

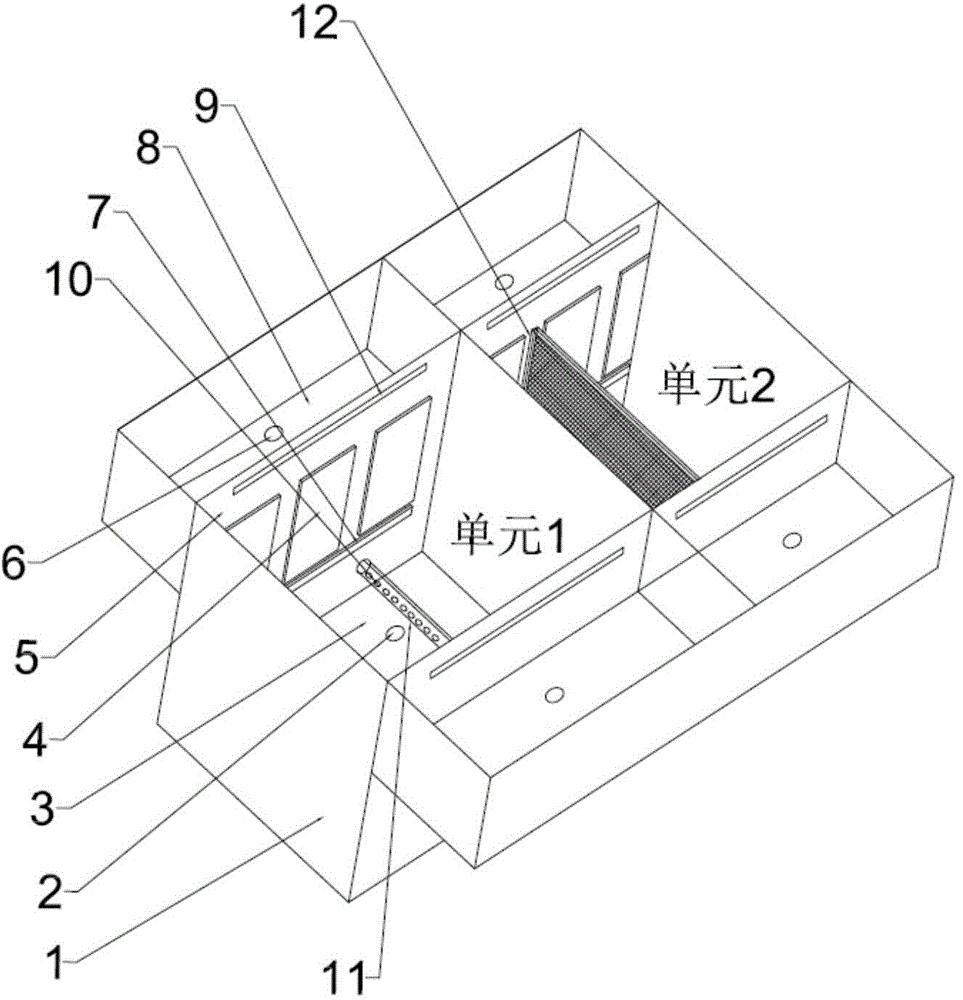

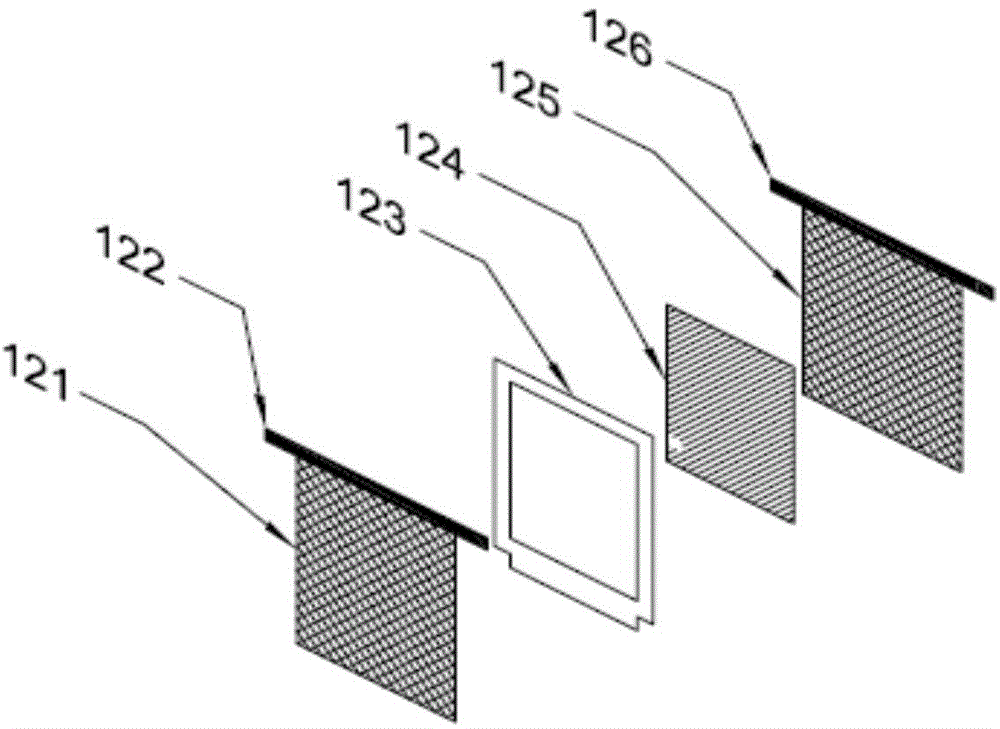

[0047] One unit of quasi-zero pitch electrolytic cell is adopted, and the electrolytic cell contains 2 electrode assemblies. The cathode terminal and the anode terminal of the two electrode assemblies are respectively connected in parallel. Finally, the cathode terminal and the anode terminal connected together in parallel are connected to a pulsed DC power supply.

[0048] Taking the treatment of landfill leachate in a garbage dump as an example, under the same current density, the single-stage (including 1 cathode and 1 anode) cell The pressure data are shown in Table 1.

[0049] Table 1:

[0050]

[0051] Take 10L of landfill leachate raw water, and use a quasi-zero pole distance electrolytic cell and a traditional electrolytic cell for electrolysis to reduce the COD from 2800mg·L -1 down to 2000mg·L -1 nearby. The effective electrolysis area of both electrolyzers is 400cm 2 ; The curren...

Embodiment 2

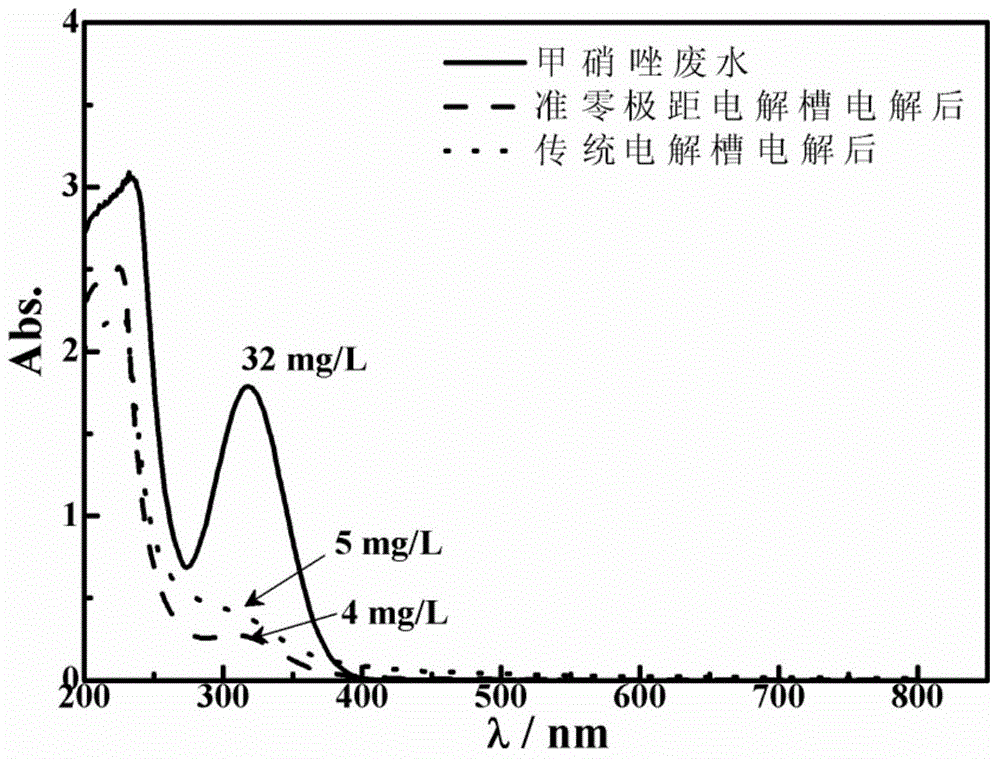

[0055] Example 2: Modification of metronidazole wastewater from a company

[0056] One unit of quasi-zero pitch electrolytic cell is adopted, and the electrolytic cell contains 4 electrode assemblies. Connect the cathode terminals and anode terminals of the four electrode assemblies in parallel respectively. Finally, the cathode terminal and the anode terminal connected together in parallel are connected to a pulsed DC power supply.

[0057] Taking the modification of metronidazole wastewater from a company as an example, under the same current density, the cell pressure of quasi-zero pitch electrolyzer, traditional electrolyzer and ion-exchange membrane electrolyzer single-stage (including 1 cathode and 1 anode) cell The data are shown in Table 3.

[0058] table 3:

[0059]

[0060] Take 10L of metronidazole wastewater, and use a quasi-zero pole distance electrolyzer and a traditional electrolyzer for electrolysis, and the concentration of metronidazole will be changed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com