Method for recovering ammonia nitrogen in wastewater

A technology for wastewater and ammonia nitrogen, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high cost of chemicals and reduced removal rate of ammonia nitrogen, and achieves reduction of cost of chemicals, high recovery efficiency, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

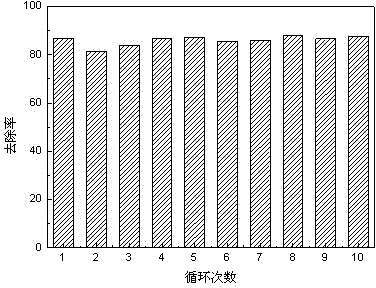

Embodiment 1

[0022] The method for recovering ammonia nitrogen in coal gasification wastewater described in the present embodiment specifically comprises the following steps:

[0023] (1) Put the magnesium ammonium phosphate crystals recovered in the wastewater treatment into the acid solution for acid hydrolysis, acidolysis at 10°C for 3 hours, and prepare a magnesium ammonium phosphate solution with a mass fraction of 20%; inject the magnesium ammonium phosphate solution into In the anode chamber, keep the current density at 20ma / cm 2 Under the conditions of separation for 3 hours, the separated anode chamber and cathode chamber products were obtained.

[0024] (2) Add the anode chamber and cathode chamber products obtained in step (1) to the wastewater, so that mg 2+ : Ammonia nitrogen in wastewater: po 4 3- The molar ratio is 1.4:1:0.6, the anode and cathode products form ammonium magnesium phosphate crystals with the ammonia nitrogen in the wastewater, precipitate and separate from...

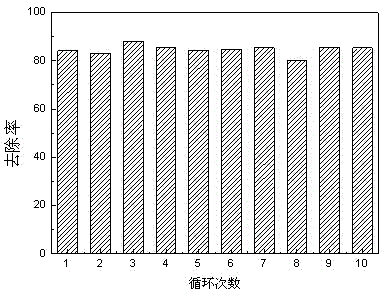

Embodiment 2

[0029] The method for reclaiming ammonia nitrogen in the coking wastewater described in the present embodiment specifically comprises the following steps:

[0030] (1) Put the magnesium ammonium phosphate crystals recovered in wastewater treatment into the acid solution for acid hydrolysis, acidolysis at 60°C for 1 hour, and prepare a magnesium ammonium phosphate solution with a mass fraction of 30%. Inject the magnesium ammonium phosphate solution into the anode chamber and keep the current density at 10ma / cm 2 Under the conditions of separation for 2 hours, the separated anode chamber and cathode chamber products were obtained.

[0031] (2) Add the anode chamber and cathode chamber products obtained in step (1) to the wastewater, so that mg 2+ : Ammonia nitrogen in wastewater: po 4 3- The molar ratio is 0.9:1:1.3, the anode and cathode products form ammonium magnesium phosphate crystals with the ammonia nitrogen in the wastewater, precipitate and separate from the wastewa...

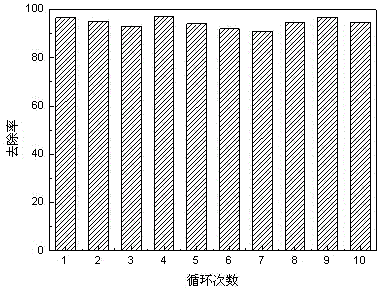

Embodiment 3

[0035] A kind of method of the recovery of ammonia nitrogen in the economical vanadium waste water of the present embodiment, its steps are:

[0036] (1) Dissolve the magnesium ammonium phosphate crystals recovered in wastewater treatment in an acid solution, acidolyze at 30°C for 1 hour, and prepare a magnesium ammonium phosphate solution with a mass fraction of 50%. Inject the magnesium ammonium phosphate solution into the separation pole chamber and keep the current density at 40ma / cm 2 Under the conditions of separation for 2 hours, the separated anode chamber and cathode chamber products were obtained.

[0037] (2) Add the anolyte and cathodic precipitation obtained in step (1) to the wastewater, so that mg 2+ : Ammonia nitrogen in wastewater: po 4 3- The molar ratio is 1.2:1:1.1, the anode and cathode products form ammonium magnesium phosphate crystals with the ammonia nitrogen in the wastewater, precipitate and separate from the wastewater.

[0038] (3) Recover the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com