Vanillin menthyl formate preparation method, and cigarette prepared with vanillin menthyl formate

A technology of menthyl formic acid and vanillin ester, which is applied in the field of tobacco flavoring, can solve the problems of poor sweetness quality, strong volatility, pungent smell and bitter taste, etc., and achieves easy industrial production, mild reaction conditions and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

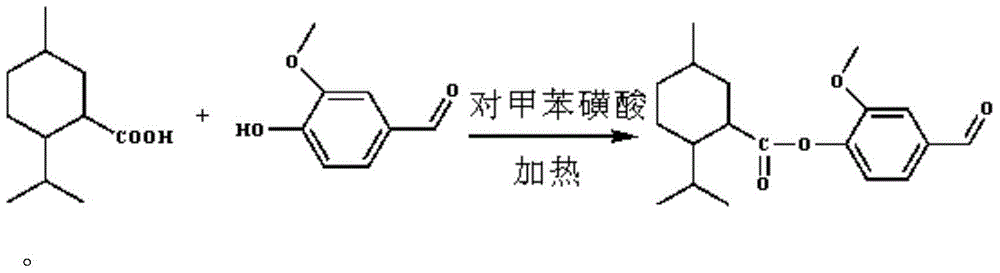

[0018] The preparation method of vanillin menthyl formate is as follows:

[0019] Add solvent toluene, menthyl formic acid and vanillin in the reactor equipped with agitator, water separator, reflux condenser and thermometer, and react under the action of catalyst p-toluenesulfonic acid, its chemical reaction formula is

[0020]

[0021] Wherein the molar ratio of menthyl formic acid and vanillin is 1:1~2, the molar ratio of menthyl formic acid and p-toluenesulfonic acid is 1:0.05~0.3, the molar ratio of menthyl formic acid and toluene is 1:5 ~20°C, stir and reflux for 1~5h at a heating temperature of 90~140°C;

[0022] After the reaction between menthyl formic acid and vanillin is completed, add dilute sodium carbonate solution to the mixing container, and then wash with water for 1 to 3 times; wherein the volume fraction of sodium carbonate is 10 to 30 times that of toluene, and the volume fraction of water is 15 to 50 times the volume fraction of toluene;

[0023] Afte...

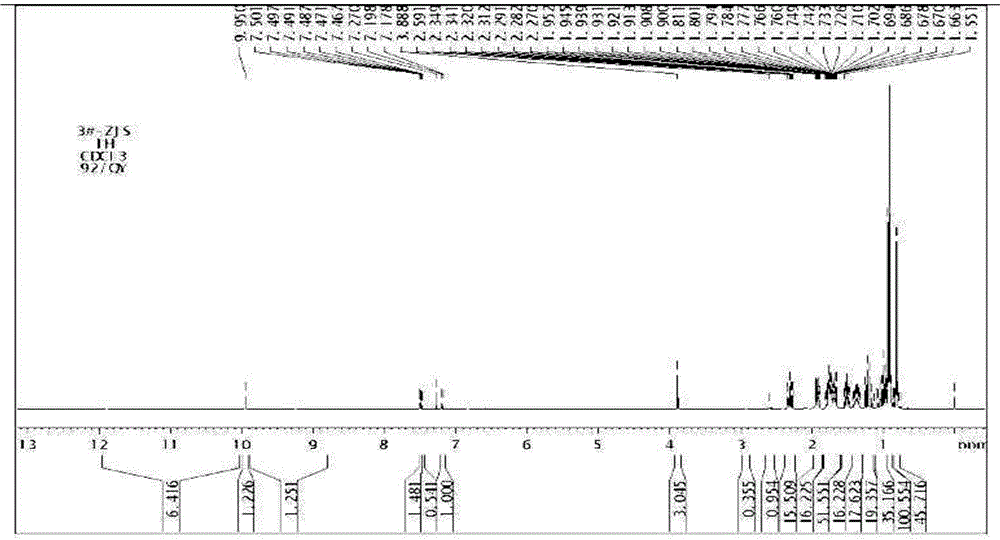

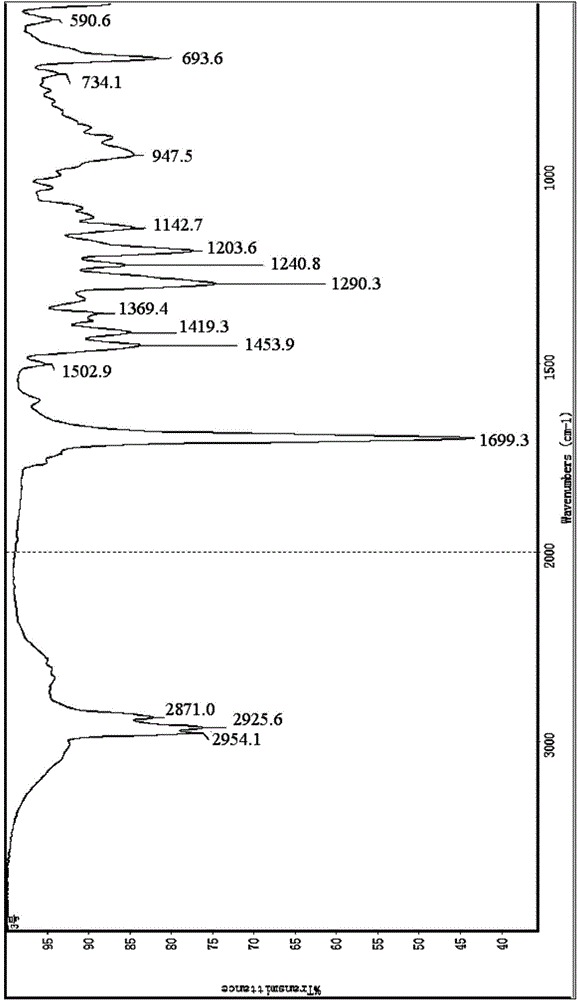

Embodiment 1

[0033] In a three-necked flask equipped with a stirrer, a water separator, a reflux condenser, and a thermometer, add 1.86g (0.010mol) of menthyl formic acid, 1.52g (0.010mol) of vanillin, and 0.2g (0.001mol) of p-toluenesulfonic acid. mol), add an appropriate amount of water-carrying agent toluene 8ml, reflux reaction at 105°C for 2.5h, after esterification, add 80ml of dilute sodium carbonate solution to the reaction solution, then add 120ml of water to wash twice, and distill under reduced pressure to remove the solvent , Purification was further achieved by silica gel column chromatography, the eluent was v (petroleum ether: ethyl acetate) = 5:1, and 2.34 g of vanillin menthyl formate was obtained. The vanillin menthyl formate was dissolved in 1000 times of 95% ethanol, and then the vanillin menthyl formate solution and the shredded tobacco were uniformly sprayed in the shredded tobacco according to the mass ratio of 0.05:100.

Embodiment 2

[0035] In a three-necked flask equipped with a stirrer, a water separator, a reflux condenser, and a thermometer, add 3.72 g (0.020 mol) of menthyl formic acid, 4.56 g (0.030 mol) of vanillin, and 0.8 g (0.004 mol) of p-toluenesulfonic acid. mol), add an appropriate amount of water-carrying agent toluene 30ml, reflux at 120°C for 3.5h, after esterification, add 500ml of dilute sodium carbonate solution to the reaction solution, then add 700ml of water to wash twice, and distill under reduced pressure to remove the solvent , Purification was further achieved by silica gel column chromatography, the eluent was v (petroleum ether: ethyl acetate) = 8:1, and 4.92 g of vanillin menthyl formate was obtained. The vanillin menthyl formate was dissolved in 1000 times of 70% ethanol, and then the vanillin menthyl formate solution and the shredded tobacco were uniformly sprayed in the shredded tobacco according to the mass ratio of 0.5:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com