Preparation method of polyaniline and derivative nanofiber

A technology of aniline derivatives and nanofibers, which is applied in nanotechnology, nanotechnology, fiber chemical characteristics, etc., can solve the problems of polyaniline and its derivatives that are difficult to control the microscopic morphology, high preparation cost, and complicated preparation methods. Achieve the effect of avoiding secondary nucleation phenomenon, time efficient and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through the accompanying drawings and examples, but the protection scope of the present invention is not limited to the content described.

[0021] Example 1 :

[0022] (1) First add 15mL of 1mol / L HCl aqueous solution into a 20ml centrifuge tube;

[0023] (2) Use a pipette to measure 0.05ml of aniline (AN) solution and add it to the aqueous solution containing doped hydrochloric acid, shake well to fully dissolve the monomer;

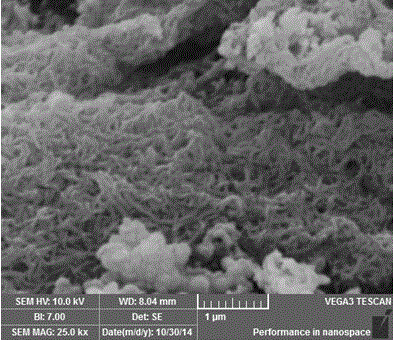

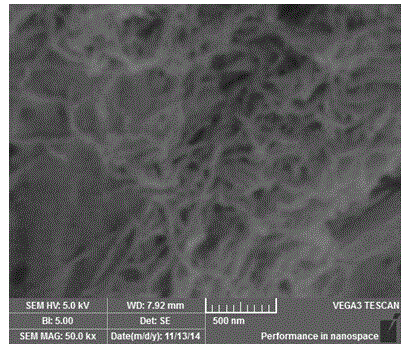

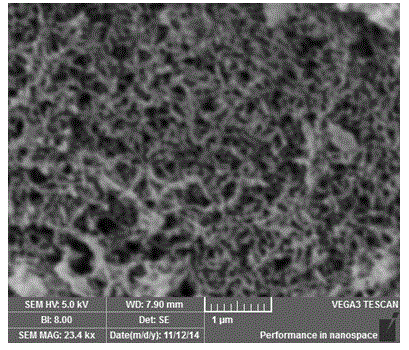

[0024] (3) Weigh 0.1251g of ammonium persulfate (APS) with an analytical balance, and quickly add it to the protonate solution formed in step (2) ([AN]:[APS]=1:1), without stirring , directly put it into a centrifuge for centrifugal polymerization, adjust the centrifugal speed to 500r / min, react for 0.1h, pour off the clear liquid, and dry the obtained polyaniline at 60°C for 12h in a vacuum to obtain high-quality polyaniline. Aniline nanofibers.

[0025] Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com