Piezoelectric type two-block cascaded micro mechanical filter

A piezoelectric and micro-mechanical technology, applied in the direction of electrical components, impedance networks, etc., can solve the problem that the adjustment of the center frequency and bandwidth of the filter is not very flexible, there are few types of piezoelectric filters, and the bandwidth of piezoelectric filters is narrow and other problems, to achieve the effect of sharp cut-off performance, simple and compact overall structure, and high Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

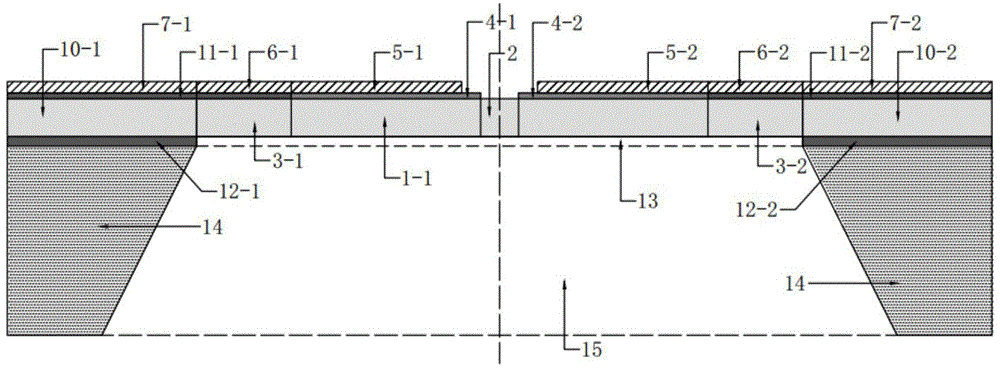

[0021] In this embodiment, an SOI substrate is used to make a filter, and the SOI substrate is composed of a thick polysilicon substrate, a 1 μm silicon dioxide insulating layer and a 10 μm single crystal silicon structure layer.

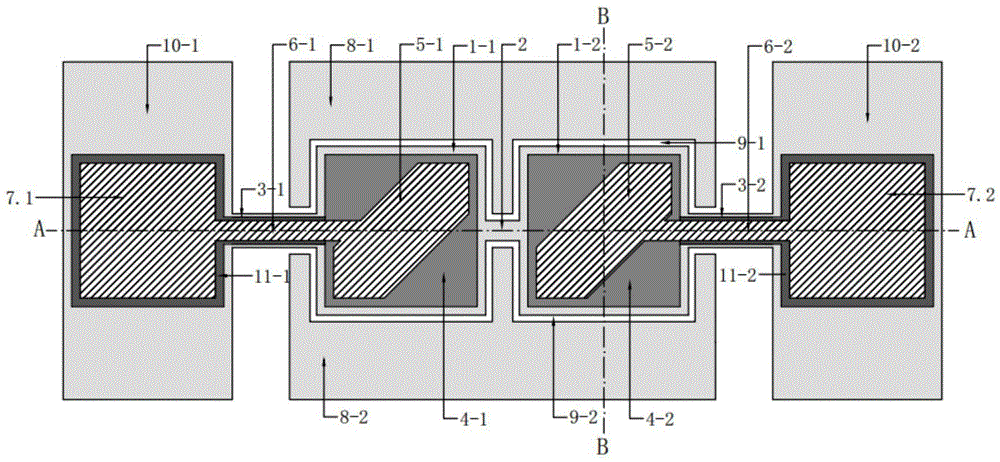

[0022] The structure of the piezoelectric two-block cascaded micromechanical filter is as follows: figure 1 As shown, when the filter is made:

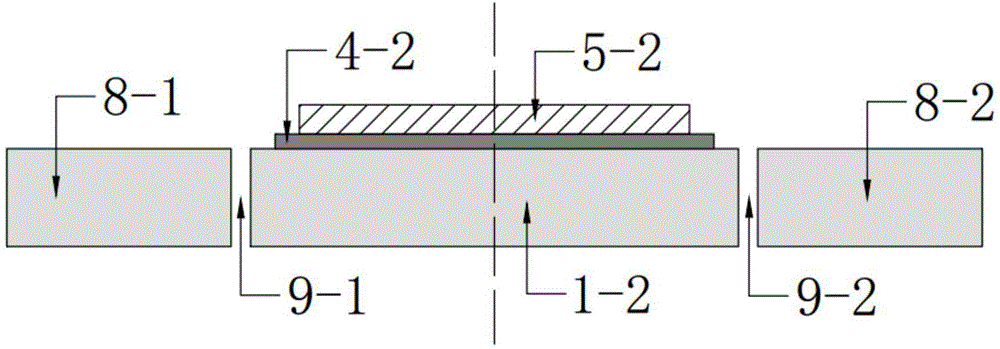

[0023] First grow a layer of silicon dioxide insulating layer on the single crystal silicon of the SOI substrate, apply photoresist photolithography, and use reactive ion etching to obtain silicon dioxide layers 11-1, 11 covering the support beams and support platforms -2; then use reactive sputtering to obtain a piezoelectric film, and then use wet etching to obtain piezoelectric film layers 4-1 and 4-2 covering the vibration block;

[0024] Reactive sputtering is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com