A kind of device and method for producing hydrogen-rich gas by biomass graded gasification

A biomass and hydrogen-rich technology, applied in the manufacture of combustible gases, chemical instruments and methods, biofuels, etc., can solve the problems of many components, high tar content, and difficult conversion and removal, so as to achieve conversion and utilization, and realize rich Collect and solve the effect of downstream equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

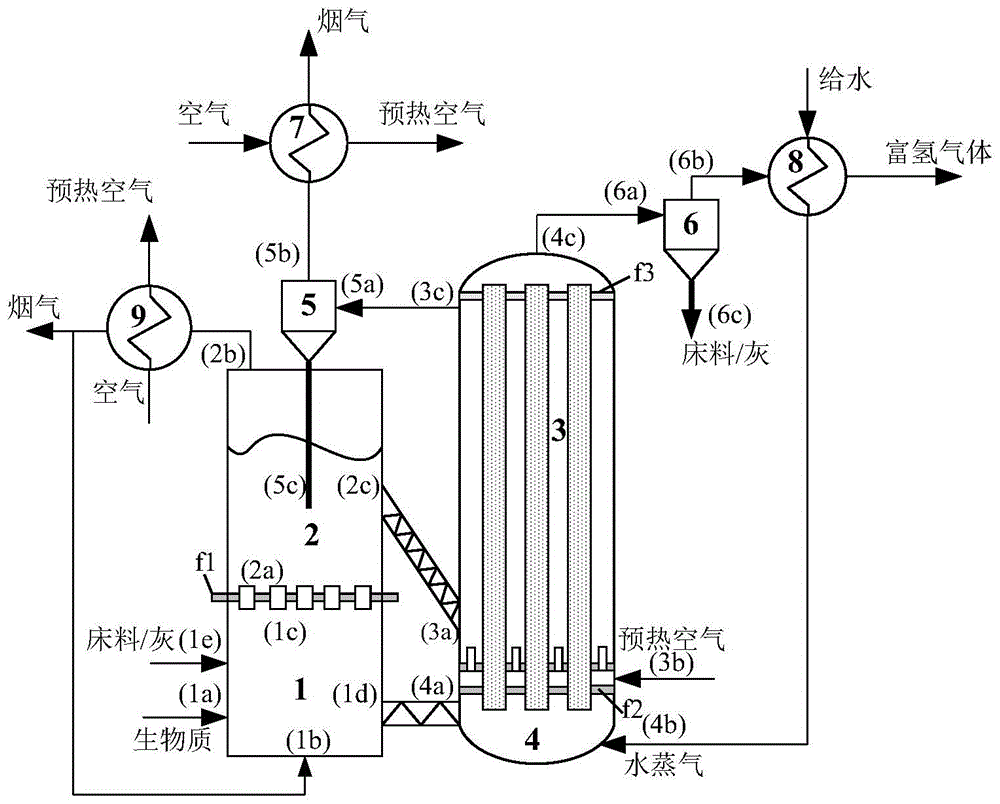

[0041] like figure 1 Shown is a device for producing hydrogen-rich gas by staged gasification of biomass, which is a circulation device formed by sequentially connecting a pyrolysis reactor 1, an oxidation reactor 2, a regeneration reactor 3, and a gasification reactor 4; There are regeneration-cyclone separator 5, gasification-cyclone separator 6, No. 1 flue gas cooler 7 and No. 2 flue gas cooler 9, steam generator 8 and several connecting pipelines. Among them, the pyrolysis reactor 1 and the oxidation reactor 2 adopt a moving bed or a bubbling fluidized bed, and the regeneration reactor 3 and the gasification reactor 4 adopt a circulating fluidized bed or a transport bed.

[0042] The pyrolysis reactor 1 is placed on the top of the oxidation reactor 2 and is directly connected; the pyrolysis reactor 1 and the oxidation reactor 2 are separated by an air distribution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com