Manufacturing technique of industrial binder asphalt

A technology of binder asphalt and production process, which is applied in the direction of chemical processing of tar asphalt/petroleum asphalt/natural asphalt, etc., which can solve the problems of long process, high requirements for equipment valves, and high safety risks, and achieve the increase of adjustment flexibility , high product quality, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

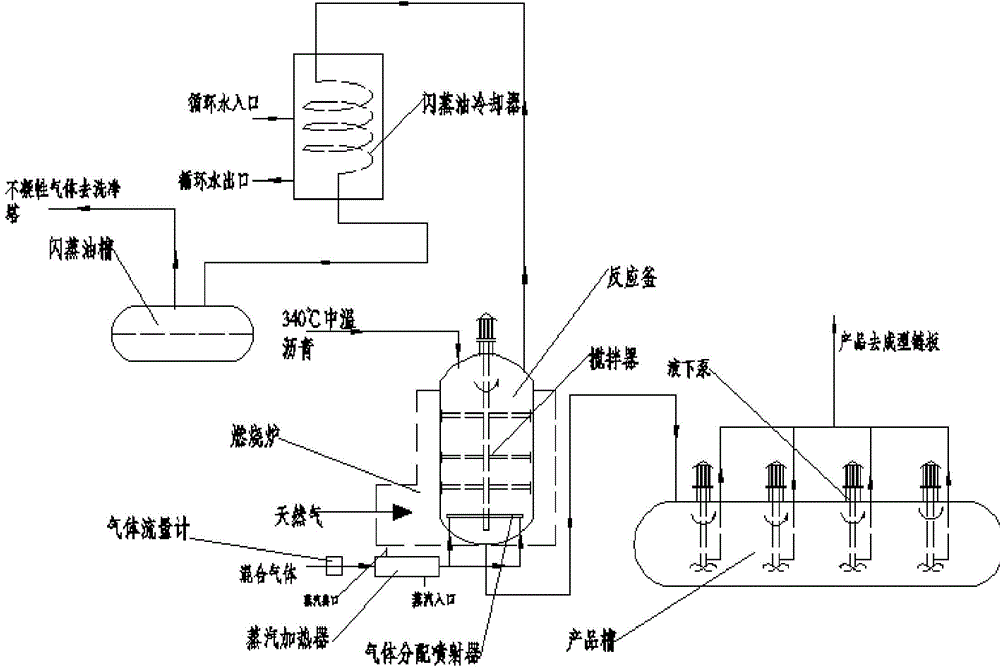

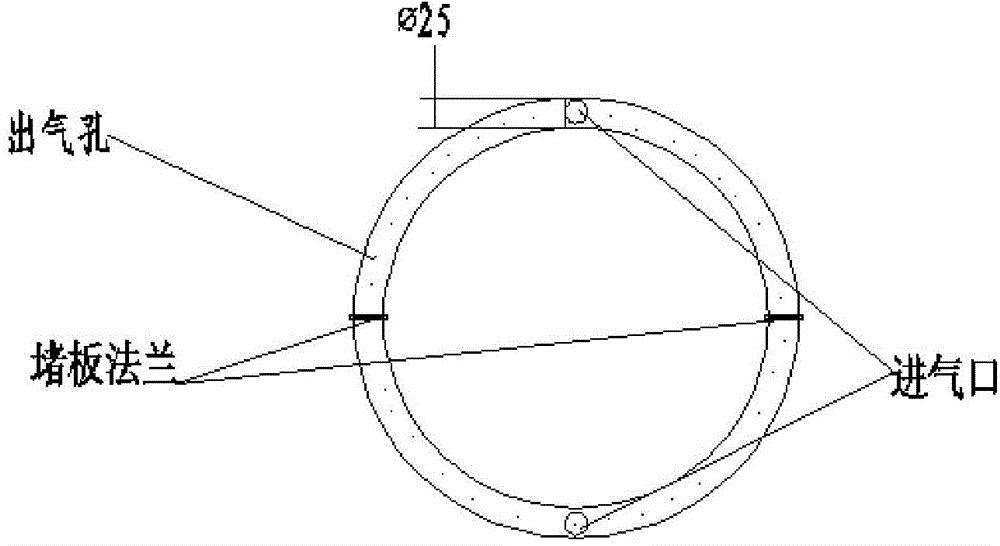

[0023] A new type of production process for industrial binder asphalt, such as figure 1 As shown, the temperature of the asphalt sent from the asphalt tower is about 340°C, adjust the asphalt liquid level of the reactor, and the liquid level is generally controlled at 2 / 3 of the volume of the reactor (the volume of the reactor is 20m 3 ), and by controlling the inflow rate of asphalt, the reaction time is controlled to be 4 hours, and the temperature in the reactor is adjusted to 310°C by heating the reactor with a natural gas heating furnace. Reaction, at the same time, the mixed gas of nitrogen and oxygen (oxygen volume content is 0.05%) is heated to 300°C by a steam heater, and the flow rate is controlled at 27m 3 / h enters the reactor from the bottom of the reactor through the mixed gas distribution injector. The mixed gas injector is an annular tubular structure with a pipe diameter of 25mm and a size of 60% of the inner diameter of the reactor. The gas inlet port is fe...

Embodiment 2

[0026] The asphalt sent from the asphalt tower has a temperature of about 340°C. Adjust the asphalt liquid level of the reactor. The liquid level is generally controlled at 2 / 3 of the volume of the reactor (the volume of the reactor is 20m 3 ), and by controlling the inflow rate of asphalt, the reaction time is controlled to be 4 hours, and the temperature in the reactor is adjusted to 320 ° C by heating the reactor with a natural gas heating furnace. Reaction, at the same time, the mixed gas of nitrogen and oxygen (oxygen volume content is 4%) is heated to 300°C by a steam heater, and the flow rate is controlled at 27m 3 / h enters the reactor from the bottom of the reactor through the mixed gas distribution injector. The mixed gas injector is an annular tubular structure with a pipe diameter of 25mm and a size of 60% of the inner diameter of the reactor. The gas inlet port is fed from the bottom of the injector. A plurality of air outlets are evenly distributed on the annul...

Embodiment 3

[0029] The asphalt sent from the asphalt tower has a temperature of about 340°C. Adjust the asphalt liquid level of the reactor. The liquid level is generally controlled at 2 / 3 of the volume of the reactor (the volume of the reactor is 20m 3 ), control the reaction time to be 5 hours, adjust the temperature in the reactor to be 360°C by heating the reactor with a natural gas heating furnace, at the same time, start the stirrer, adjust the rotating speed at 150 rpm, and carry out the high-temperature polycondensation reaction. At the same time, nitrogen and After the mixed gas of oxygen (oxygen volume content is 5%) is heated to 350°C by a steam heater, the flow rate is controlled at 40m 3 / h enters the reactor from the bottom of the reactor through the mixed gas distribution injector. The mixed gas injector is an annular tubular structure with a pipe diameter of 25mm and a size of 60% of the inner diameter of the reactor. The gas inlet port is fed from the bottom of the injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com