Technology for recovering platinum, palladium and rhodium from spent auto-catalyst

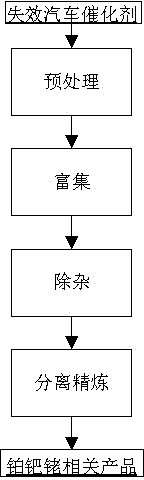

An auto catalyst and platinum-palladium technology, which is applied in the field of recovering platinum, palladium and rhodium, can solve the problems of polluting the environment with nitrogen oxides, high content of leaching residues and high direct yield, and achieve good environmental protection, high direct yield and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

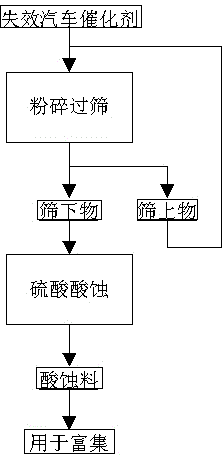

[0034] (1) Pretreatment

[0035] The exhausted automobile catalyst is crushed and sieved, the sieve mesh is 205 mesh, the sieve is returned to continue to be crushed and then sieved, and the undersieve is treated with sulfuric acid acid etching, the temperature of sulfuric acid acid etching is 250 ℃, and the concentration of sulfuric acid is 65%. Acid etching material, used for enrichment process;

[0036] During the crushing and sieving process, fans are used to draw air and dust is collected by cloth bags. During the acid etching process, the equipment is sealed, and the gas generated enters the third stage of absorption through the exhaust. The acidic water absorption solution is returned to acid etching;

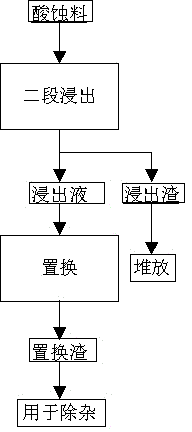

[0037] (2) Enrichment

[0038] The acid etching material is subjected to secondary chlorination leaching, and the leaching solution is replaced to obtain platinum, palladium and rhodium replacement slag, and the leaching slag is piled up for storage;

[0039] Seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com