Submicron-scale low-loss single-crystal yttrium-iron-garnet film liquid-phase epitaxy preparation method

A yttrium-iron garnet, sub-micron technology, applied in the field of liquid phase epitaxy preparation of sub-micron low-loss single crystal yttrium iron garnet thin film, can solve the problem that cannot meet the requirements of spin device ferromagnetic resonance line width, shorten Growth time and other issues, to achieve the effect of high loss, large growth interface roughness, and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A liquid phase epitaxy preparation method for a submicron low-loss single crystal yttrium iron garnet thin film, specifically comprising the following steps:

[0026] Step 1: Take Y 2 o 3 , Fe 2 o 3 , PbO and B 2 o 3 As the raw material, the above-mentioned raw materials were accurately weighed, wherein, Y 2 o 3 , Fe 2 o 3 , PbO and B 2 o 3 The mass ratio of the mixture is 0.486:10.315:87.45:1.748, ground and mixed in an agate mortar, placed in a platinum crucible, melted at 1100-1150°C for 24 hours, then stirred at 1000°C for 12 hours, and mixed evenly to obtain a melt;

[0027] Step 2: Using gadolinium gallium garnet (GGG) as the substrate, firstly, the gadolinium gallium garnet substrate was ultrasonically cleaned twice in deionized water, twice in acetone, twice in alcohol, and The cleaning time in deionized water, acetone, and alcohol is 10-15 minutes; then the substrate is placed in a mixture of concentrated sulfuric acid and nitric acid with a volume r...

Embodiment

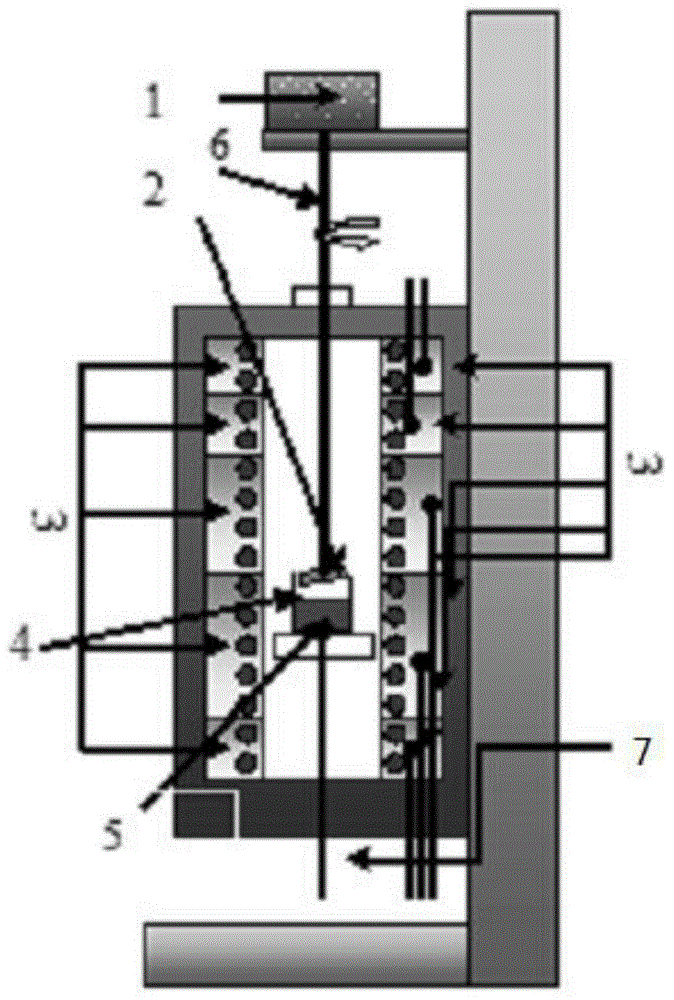

[0030] The single crystal YIG garnet film of the present invention is prepared by liquid phase epitaxy, and the equipment used is a liquid phase epitaxy furnace, such as figure 1 shown. Among them, 1 is a motor; 2 is a GGG substrate; 3 is a heater; 4 is a crucible; 5 is a melt; 6 is a ceramic pulling rod; 7 is a rotating shaft.

[0031] The liquid phase epitaxy preparation method of a submicron low loss single crystal yttrium iron garnet film provided by the present invention specifically comprises the following steps:

[0032] Step 1, preparation of melt: with Y 2 o 3 , Fe 2 o 3 , PbO and B 2 o 3 As the raw material, the above-mentioned raw materials were accurately weighed, wherein, Y 2 o 3 , Fe 2 o 3 , PbO and B 2 o 3 The mass ratio is 0.486:10.315:87.45:1.748, carefully ground and mixed in an agate mortar, placed in a platinum crucible, melted at 1100°C for 24h, then stirred at 1000°C for 12h, mixed well, and then lowered the temperature to Growth temperature;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com