Preparation method for simple enzyme biosensor

A biosensor, a simple technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of long preparation cycle and unsuitable for large-scale production, and achieve good performance, accelerated electron transmission rate, and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

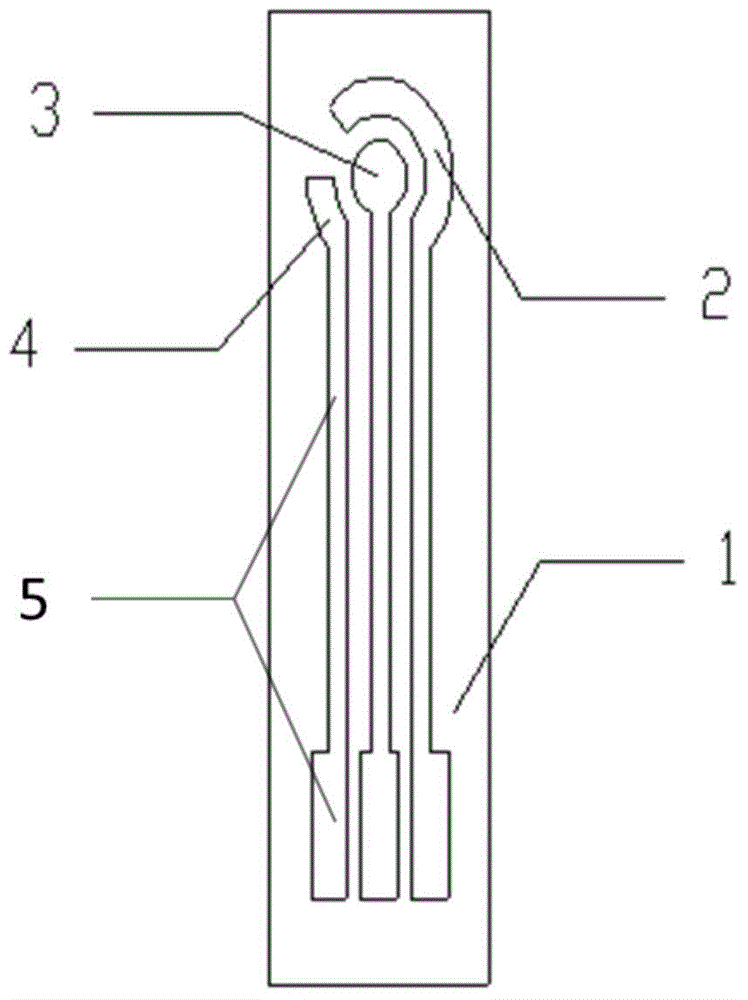

[0023] A method for preparing an enzyme biosensor, comprising the following preparation steps:

[0024] (1) Configure 1mM·L -1 K 4 Fe(CN) 6 and FeCl 3 , synthesize Prussian blue by chemical method at equimolar concentration, the centrifugation rate is 3000r / min, and the centrifugation time is 30min;

[0025] (2) Mix the synthesized Prussian blue and carbon ink at a mass ratio of 1:1, and make it evenly mixed to prepare carbon ink / Prussian blue mixed ink;

[0026] (3) Enzyme biosensors were prepared on the support PVC by screen printing technology;

[0027] (4) preparing a glucose oxidase solution with a concentration of 500U / ml, and adding glutaraldehyde to the solution so that the mass percentage of glutaraldehyde in the glucose oxidase solution is 1%;

[0028] (5) Pipette the enzyme solution and apply it evenly on the working electrode 3 so that there is 20 μl of the enzyme solution per square centimeter of the working electrode 3, and place it in a refrigerator to dry ...

Embodiment 2

[0031] A method for preparing an enzyme biosensor, comprising the following preparation steps:

[0032] (1) Configure 100mM·L -1 K 4 Fe(CN) 6 and FeCl 3 , Prussian blue was synthesized by chemical method at equimolar concentration, the centrifugation rate was 10000r / min, and the centrifugation time was 3min;

[0033] (2) Mix the synthesized Prussian blue and carbon ink in a mass ratio of 1:99, and make it evenly mixed to prepare carbon ink / Prussian blue mixed ink;

[0034] (3) Enzyme biosensors were prepared on the support PET by screen printing technology;

[0035] (4) preparation concentration is the glucose oxidase solution of 5000U / ml, and adds glutaraldehyde in the solution, makes the mass percent concentration that glutaraldehyde accounts for in the glucose oxidase solution be 6%;

[0036] (5) Pipette the enzyme solution and apply it evenly on the working electrode 3 so that there is 200 μl of the enzyme solution per square centimeter of the working electrode 3, and...

Embodiment 3

[0039] A method for preparing an enzyme biosensor, comprising the following preparation steps:

[0040] (1) Configure 80mM·L -1 K 3 Fe(CN) 6 and (NH 4 ) 2 Fe(SO 4 ) 2 , Prussian blue was synthesized by chemical method at equimolar concentration, the centrifugation rate was 8000r / min, and the centrifugation time was 15min;

[0041] (2) Mix the synthesized Prussian blue and carbon ink in a mass ratio of 2:3, and make it evenly mixed to prepare carbon ink / Prussian blue mixed ink;

[0042] (3) Enzyme biosensors were prepared on the support alumina by screen printing technology;

[0043] (4) preparation concentration is the glucose oxidase solution of 2500U / ml, and adds glutaraldehyde in the solution, makes the mass percent concentration that glutaraldehyde accounts for in the glucose oxidase solution be 10%;

[0044] (5) Pipette the enzyme solution and apply it evenly on the working electrode 3 so that there is 120 μl of enzyme solution on the working electrode 3 per squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com