Production method for livestock feed additive capable of adsorbing vomitoxin and protecting intestinal tract

A technology of feed additive and vomitoxin, which is applied in the field of livestock feed additives, can solve the problems of not being able to protect the intestinal health of livestock and not being able to absorb vomitoxin, and achieve the effects of low cost, easy control and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

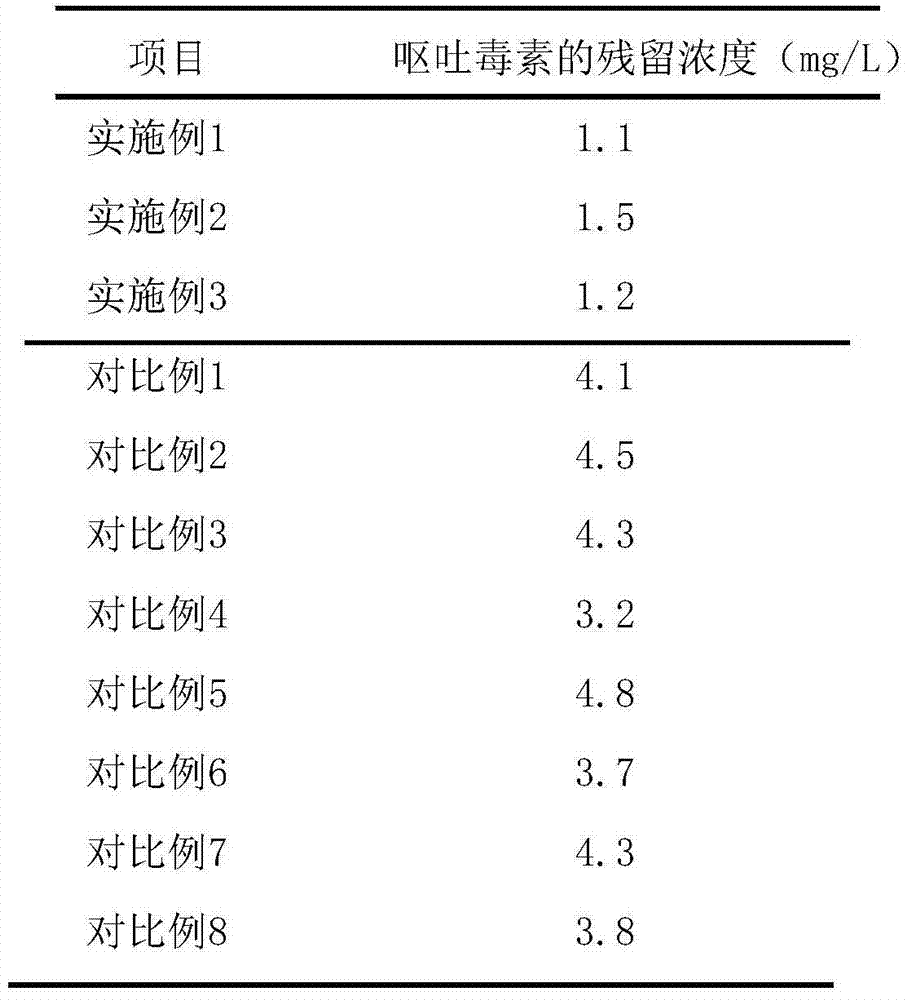

Examples

Embodiment 1

[0027] This embodiment relates to a production method of a livestock feed additive that absorbs vomitoxin and protects the intestinal tract, which consists of the following steps:

[0028] Step 1: Attapulgite clay, bentonite, and zeolite raw ore are air-dried until they are mixed according to a weight ratio of 2:2:1, coarsely crushed into a particle mixture with a particle diameter of 3mm, and acrylic acid equivalent to 2% by weight of the particle mixture is added. Sodium bicarbonate and sodium carbonate equivalent to 1% of the weight of the granule mixture are fully mixed to obtain mixed granules;

[0029] Step 2, spraying water to the mixed small particles to adjust the water weight content to 40%, and extruding it into a flaky clay mixture with a pair of rollers and a three-roller with a distance of 2 mm;

[0030] Step 3: Cover the flaky clay mixture with a film, stack it for more than 15 days, dry it until the moisture content is 20%, and then put the dried flaky clay mix...

Embodiment 2

[0034] This embodiment relates to a production method of a livestock feed additive that absorbs vomitoxin and protects the intestinal tract, which consists of the following steps:

[0035] Step 1: Attapulgite clay, bentonite, and zeolite raw ore are air-dried until they are mixed according to a weight ratio of 2:2:1, coarsely crushed into a particle mixture with a particle diameter of 2mm, and 2% of the weight of the particle mixture is added. Sodium bicarbonate and sodium carbonate equivalent to 1% of the weight of the granule mixture are fully mixed to obtain mixed granules;

[0036] Step 2, spraying water to the mixed small particles to adjust the water weight content to 42%, and extruding into a flaky clay mixture with a pair of rollers and a three-roller with a distance of 1 mm;

[0037] Step 3: Cover the flaky clay mixture with a film, stack it for more than 15 days, dry it to a moisture content of 5%, and then put the dried flaky clay mixture and water into a stainless ...

Embodiment 3

[0041] This embodiment relates to a production method of a livestock feed additive that absorbs vomitoxin and protects the intestinal tract, which consists of the following steps:

[0042] Step 1: Attapulgite clay, bentonite, and zeolite raw ore are air-dried until they are mixed according to a weight ratio of 2:2:1, coarsely crushed into a particle mixture with a particle diameter of 4mm, and acrylic acid equivalent to 2% of the particle mixture weight is added. Sodium bicarbonate and sodium carbonate equivalent to 1% of the weight of the granule mixture are fully mixed to obtain mixed granules;

[0043] Step 2, spraying water to the mixed small particles to adjust the water weight content to 38%, and extruding into a sheet-like clay mixture with a pair of rollers and a three-roller with a distance of 1mm;

[0044]Step 3: Cover the flaky clay mixture with a film, stack it for more than 15 days, dry it until the moisture content is 10%, and then put the dried flaky clay mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com