Resin with specific adsorption for cephalosporin C and preparation method therefor

A specific and spore-forming technology, which is applied in the field of resin with specific adsorption to cephalosporin C and its preparation, can solve the problem that the adsorption amount and selectivity cannot be balanced, and achieve strong anti-pollution ability and high selectivity performance , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

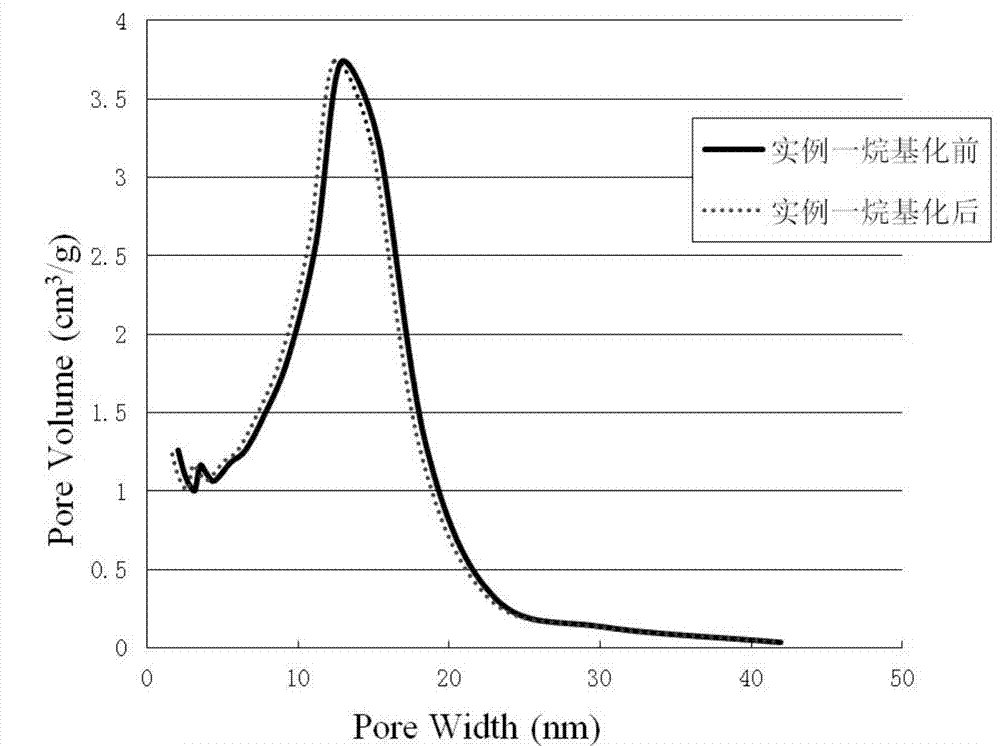

Image

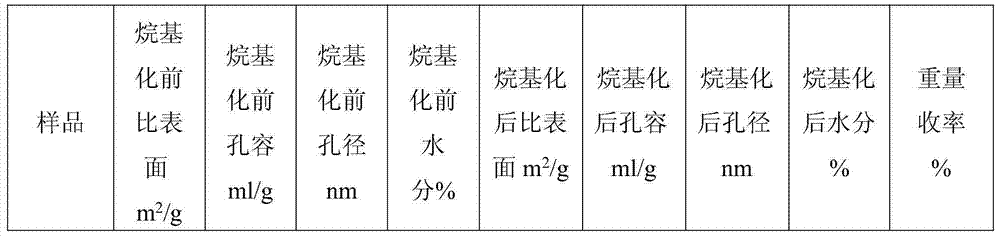

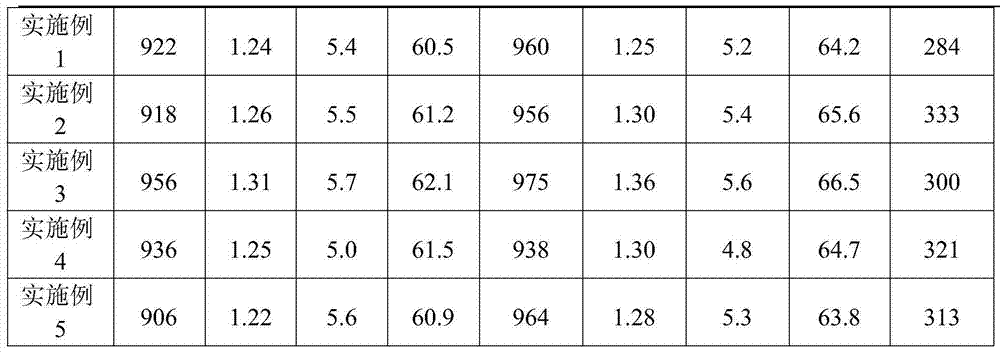

Examples

Embodiment 1

[0035] The monomer mixture that will contain 100g (80% content) divinylbenzene, 100g toluene and 50g sec-butyl acetate and 1.0g benzoyl peroxide is added in the dispersion medium solution that is made up of 500ml anhydrous salt water, 5g gelatin, stirs Make uniform droplets of a certain size, raise the temperature to 80°C, and react for 12 hours. Then drain the water, add water again, heat up to 50-60°C, stir and wash three times, add 500ml of water and heat up to azeotropic distillation to remove the porogen (toluene and sec-butyl acetate), until the condensate is almost free of oil material, stop distillation. After cooling down to room temperature, wash the spheres with a large amount of water, drain the water, then dry with hot air until the water content is below 1.0%, and sieve the spheres with 30-60 mesh to obtain 95 g of cross-linked macroporous copolymer matrix.

[0036] Add 95g of the cross-linked macroporous copolymer matrix obtained above into 450ml of nitrobenzen...

Embodiment 2

[0038] The monomer mixture that will contain 100g (80% content) divinylbenzene, 90g toluene and 150g methyl isobutyl carbinol and 1.0g benzoyl peroxide is added in the dispersion medium solution that is made up of 500ml anhydrous salt water, 5g gelatin , stirred to form uniform droplets of a certain size, heated to 75°C, and reacted for 12 hours. Then drain the water,. Then drain the water, re-add water, heat up to 50-60°C, stir and wash three times, add 500ml of water and heat up to azeotropic distillation to remove porogens (toluene and methyl isobutyl carbinol), until almost no Contains oil, stop distillation. Cool down, wash the spheres with a large amount of water, drain the water, then dry with hot air until the water content is below 1.0%, and sieve the spheres with 30-60 mesh to obtain 90 g of cross-linked macroporous copolymer matrix.

[0039] Add 90g of the cross-linked macroporous copolymer matrix obtained above into 570ml of dichloroethane, stir and swell at room...

Embodiment 3

[0041] The monomer mixture that will contain 100g (80% content) divinylbenzene, 150g toluene and 70g methyl isobutyl ketone and 1.0g benzoyl peroxide is added in the dispersion medium solution that is made up of 500ml anhydrous salt water, 5g gelatin, Stir to form uniform droplets of a certain size, raise the temperature to 75°C, and react for 12 hours. . Then drain the water, re-add water, heat up to 50-60°C, stir and wash three times, add 500ml of water and heat up to azeotropic distillation to remove porogens (toluene and methyl isobutyl carbinol), until almost no Contains oil, stop distillation. Cool down, wash the spheres with a large amount of water, drain the water, then dry with hot air until the water content is below 1.0%, and sieve the spheres with 30-60 mesh to obtain 85 g of cross-linked macroporous copolymer matrix.

[0042] The 85g cross-linked macroporous copolymer matrix obtained above was added in 510ml ethylene dichloride, stirred and swelled at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com