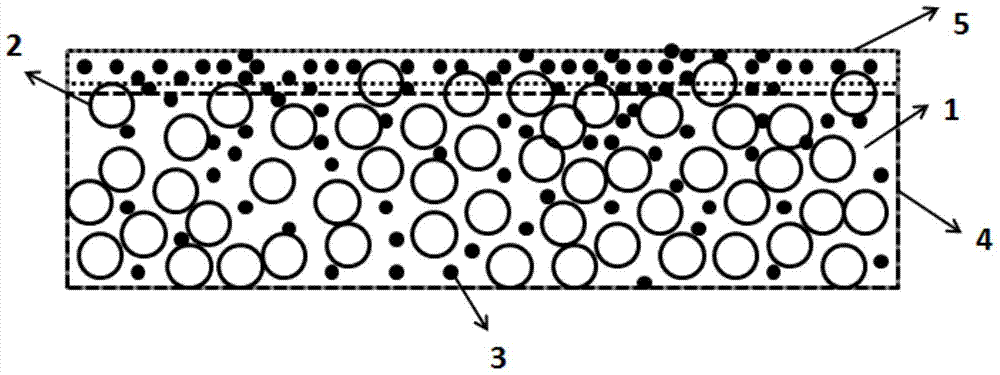

A kind of high thermal conductivity and high heat dissipation nylon composite material and its preparation method and application

A nylon composite material, high heat dissipation technology, applied in the field of polymer materials, can solve the problems of adding fins or grooves, increasing manufacturing costs, low production efficiency, etc., to reduce surface temperature, improve service life, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add high thermal conductivity magnesium oxide (average particle size 5um) into the high-speed mixer, slowly and evenly add KH550 surface modifier in the form of spray, gradually raise the temperature to 100-120°C, stir at 600 rpm for 5 minutes at high speed to achieve the surface Organic modification, using the same method to carry out surface organic modification treatment on nano zinc oxide (average particle size 200 nm) with octadecyl trimethoxysilane, and oxidize high thermal conductivity magnesium oxide, zinc oxide and nylon particles Magnesium: Zinc Oxide: Nylon is mixed in a ratio of 45:5:50 (parts by mass), plus 0.3 parts (parts by mass) of lubricant and 5 parts (parts by mass) of flame retardant, and the Down-melt extrusion and granulation to obtain nylon composite materials with high thermal conductivity and high heat dissipation.

Embodiment 2

[0037] Add alumina (average particle size 10um) and aluminum nitride (average particle size 15um) into the high-speed mixer, slowly and evenly add KH550 surface modifier in the form of spray, gradually increase the temperature to 100-120°C, 600 rpm Under high-speed stirring for 5 minutes per minute to realize surface organic modification, adopt the same method to carry out organic surface modification treatment to nano-barite powder (average particle diameter 50 nanometers) with tridecafluorooctyltrimethoxysilane, and aluminum oxide , aluminum nitride, barite powder and nylon particles are mixed in the ratio of 25:15:20:40 (parts by mass), plus 2 parts (parts by mass) of lubricant and 10 parts (parts by mass) of flame retardant, and double The screw extruder melts and extrudes at 250°C and pelletizes to obtain nylon composite materials with high thermal conductivity and high heat dissipation.

Embodiment 3

[0039] Add high thermal conductivity alumina (average particle size 10um) and boron nitride (average particle size 20um) into the high-speed mixer, slowly and evenly add KH550 surface modifier in the form of spray, and gradually increase the temperature by 100-120°C, Stir at high speed at 600 rpm for 5 minutes to achieve surface organic modification, use the same method to compound octadecyltriethoxysilane and γ-aminopropyltriethoxysilane (mass ratio 9:1) on the nano Beryllium oxide (average particle diameter 100 nanometers) carries out surface modification, and aluminum oxide, boron nitride, beryllium oxide, graphene microcrystal and nylon particle are mixed with the ratio of 35:10:10:5:40 (mass parts), Add 2 parts (parts by mass) of lubricant and 7 parts (parts by mass) of flame retardant, melt extrude and pelletize at 250° C. through a twin-screw extruder to obtain a nylon composite material with high thermal conductivity and high heat dissipation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com