Method for forming varied doping region and device thereof

A technology of variable doping and edge, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high cost, complex formation process of variable doping regions, etc., and achieve reduced chip manufacturing costs and fewer photolithography times , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

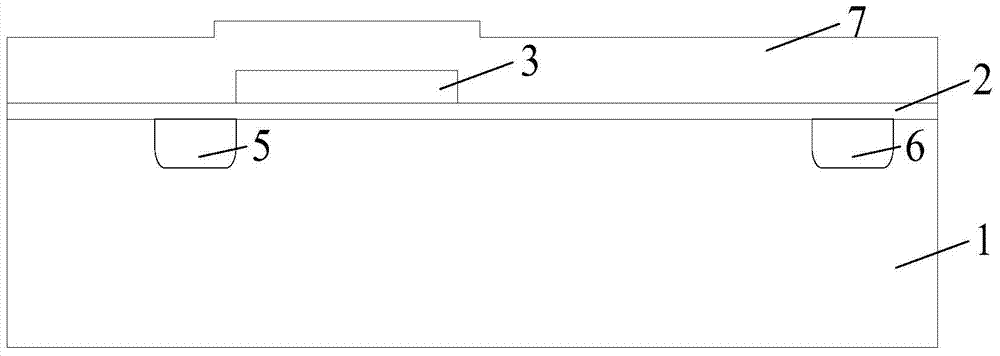

[0063] The following takes the use of silicon nitride / silicon oxide / silicon nitride sandwich structure multi-layer composite film layer to form a variable doping region as an example to describe the specific implementation process of an embodiment of the present invention in detail, see Figure 8 .

[0064] Step 801: Fabricate gate oxide layer 2 and polysilicon 3 gate on P-type substrate 1, form N+ source and drain regions, and grow a sandwich structure of silicon nitride / silicon oxide / silicon nitride multilayer on the gate oxide layer and polysilicon surface Composite film layer.

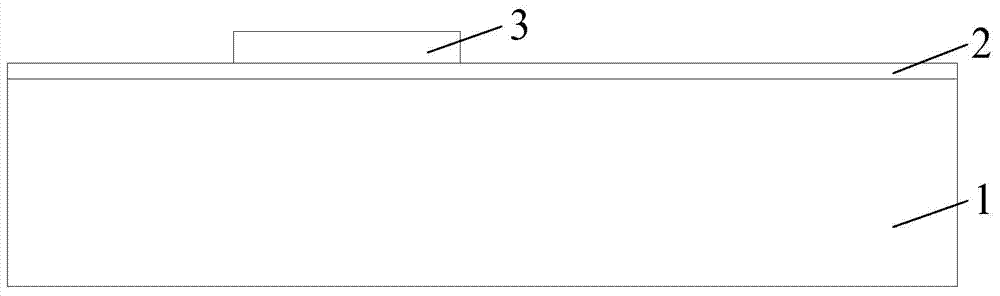

[0065] The schematic diagram of making gate oxide layer 2 and polysilicon 3 is shown in figure 1 , the growth temperature of the gate oxide layer 2 is about 900-1100° C., and the thickness is about 0.05-0.20 μm; the growth temperature of the polysilicon 3 is about 500-700° C., and the thickness is about 0.3-0.8 μm.

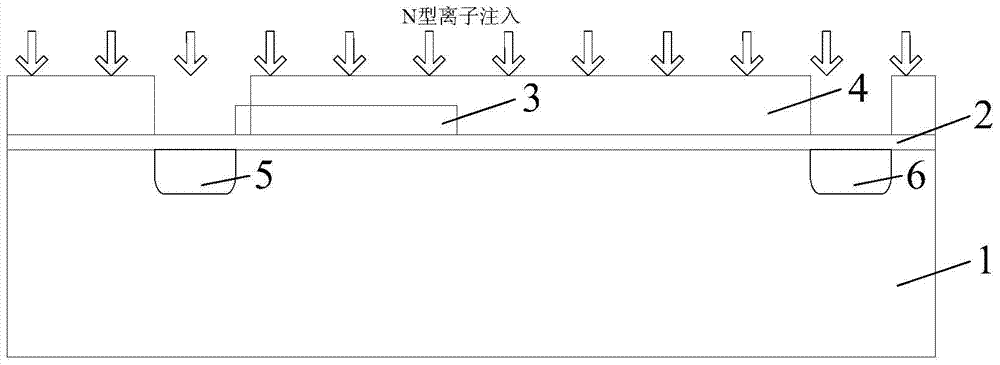

[0066] see figure 2 Phosphorus or arsenic ions are implanted after photolithog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com