DC variable frequency fan

A DC frequency conversion and fan technology, which is applied to non-variable-capacity pumps, AC motor control, components of pumping devices for elastic fluids, etc. efficiency, insufficient lightning protection measures of the controller, etc., to achieve the effect of improving fan efficiency, improving system safety performance, and high specific power consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical principle and working process of the embodiments of the present invention, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

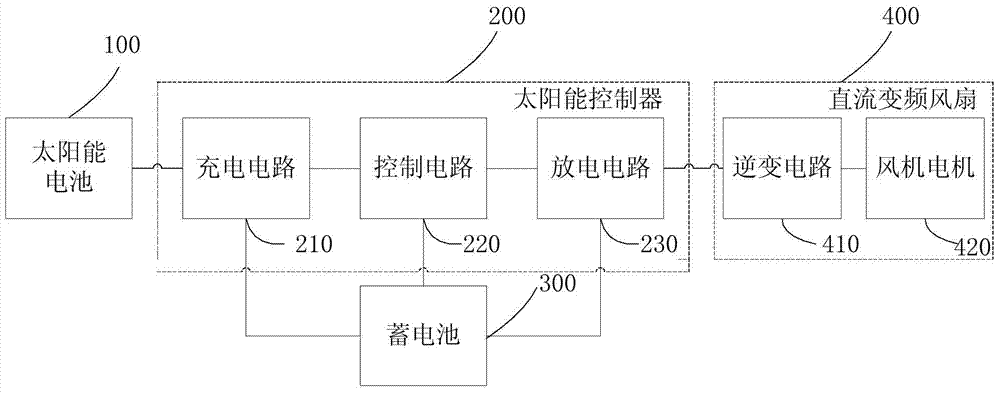

[0018] see figure 1 , shows the functional block diagram of the DC frequency conversion fan system of the present invention. The DC inverter fan system (hereinafter referred to as the system) includes a thin-film solar cell 100, a solar controller 200, a storage battery 300, and a DC inverter fan 400. The solar cell 100 is preferably a thin-film solar cell, and the solar controller 200 has a charging circuit 210 and a discharging circuit 230. And the control circuit 220, the DC variable frequency fan 400 has an inverter circuit 410 and a fan motor 420, the charging circuit 210 is connected between the solar battery 100 and the storage battery 300, the discharge circuit 230 is connected between the storage battery 300 and the inver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com