Nitraria tangutorum skin residue extract with anti-fatigue effect and preparation method thereof

The technology for extracting and extracting P. alba slag is applied in the field of P. alba slag extract and its preparation, which can solve the problems of polluted environment, difficult storage, low added value of prickly ash peel and the like, and achieves simple operation and high added value of products. , The effect of obvious anti-fatigue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

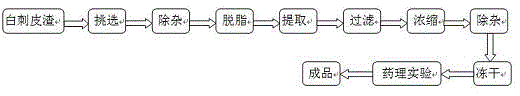

Image

Examples

Embodiment 1

[0017] Example 1: A Nitraria bark residue extract with anti-fatigue effect and its preparation method. The Nitraria skin residue is composed of steps such as selection and removal of impurities, degreasing, ultrasonic extraction, concentration, removal of impurities, centrifugation, and drying. After the skin dregs are selected and removed, pass through a 30-mesh sieve and make coarse powder to remove sand and stones; during degreasing, petroleum ether with a material-to-liquid ratio of 1:5 is refluxed at 50°C for 3 hours, and the solvent is recovered and dried for later use; during ultrasonic extraction, the temperature is controlled at 85°C , extract with 40% ethanol for 1 h under the condition of solid-liquid ratio of 1:10; filter with 80 mesh silk cloth; 0 Bx; mix chloroform and n-butanol at a ratio of 5:1, add 0.2 times the volume of the mixed solution to the concentrated solution, stir vigorously on a constant temperature magnetic stirrer for 30 minutes, and refrigerate a...

Embodiment 2

[0018] Example 2: A Nitraria bark residue extract with anti-fatigue effect and its preparation method. The Nitraria bark residue is composed of steps such as selection and removal of impurities, degreasing, ultrasonic extraction, concentration, removal of impurities, centrifugation, and drying. After the skin dregs are selected and removed, pass through a 40-mesh sieve and make coarse powder to remove sand and stones; during degreasing, petroleum ether with a material-to-liquid ratio of 1:10 is refluxed at 70°C for 2 hours, and the solvent is recovered and dried for later use; during ultrasonic extraction, the temperature is controlled at 90°C , extract with 50% ethanol for 2 hours under the condition of solid-liquid ratio of 1:20; filter with 100-mesh silk cloth; control the negative pressure at -0.07Mpa during concentration, heat at 70°C, and concentrate until the solid content is 30 0 Bx: Mix chloroform and n-butanol at a ratio of 5:1, add 0.6 times the volume of the mixed s...

Embodiment 3

[0019] Example 3: A kind of extract of Nitraria japonica skin residue with anti-fatigue effect and its preparation method. The Nitraria thorn residue is composed of steps such as selection and removal of impurities, degreasing, ultrasonic extraction, concentration, removal of impurities, centrifugation, and drying. After the skin dregs are selected and removed, pass through a 50-mesh sieve and make coarse powder to remove sand and stones; during degreasing, petroleum ether with a material-to-liquid ratio of 1:15 is refluxed at 90°C for 1 hour, and the solvent is recovered and dried for later use; during ultrasonic extraction, the temperature is controlled at 95°C , extract with 60% ethanol for 3 hours under the condition of solid-liquid ratio of 1:30; filter with 120 mesh silk cloth; 0 Bx; mix chloroform and n-butanol at a ratio of 5:1, add 1 times the volume of the mixed solution to the concentrated solution, stir vigorously on a constant temperature magnetic stirrer for 1.5h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com