Preparation method and application of oxygen reduction cathode catalyst of aluminum-air battery

A technology of aluminum-air batteries and catalysts, applied in battery electrodes, physical/chemical process catalysts, circuits, etc., can solve the problems of high price, cumbersome synthesis steps, unsuitable for promotion and mass production, and achieve low price, simple operation, The effect of promoting application and commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

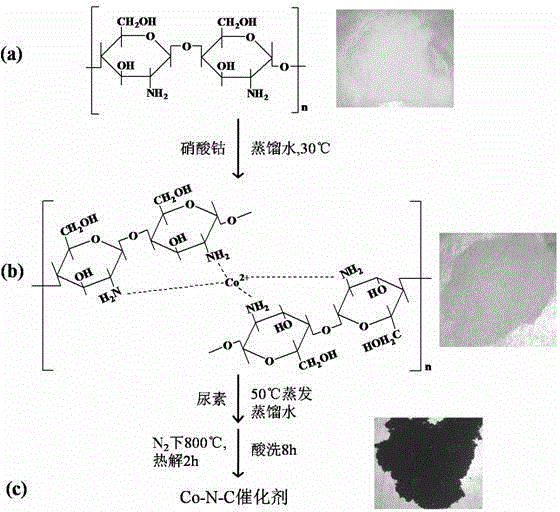

[0019] Disperse chitosan in deionized water, then slowly add cobalt nitrate aqueous solution dropwise, stir at room temperature for 2 hours, allow it to fully chelate, wash the metal chelate with deionized water 2 to 3 times, add urea in different mass ratios, Stirring was continued for 2 h, and then the water was evaporated to dryness at 50 °C, and the obtained sample was dried in a vacuum oven for 12 hours for later use. Put an appropriate amount of dried sample in a porcelain boat, put it in a tube furnace, raise the temperature up to 800 °C at a rate of 5 °C / min under the protection of nitrogen, keep it for 2 hours, and then cool it down to room temperature naturally to obtain a black powder substance. Then add it to 20 mL of 0.5 mol / L H 2 SO 4 solution, stirred at 80°C for 8 hours, washed 2-3 times with deionized water, filtered with suction, and dried at 60°C for 12 hours.

[0020] Weigh 4 mg of the above sample, put it in a 4 mL plastic bottle, and take 1900 uL of ab...

Embodiment 2

[0022] Disperse chitosan in deionized water, then slowly add cobalt nitrate aqueous solution dropwise, stir at room temperature for 2 hours, allow it to fully chelate, wash the metal chelate with deionized water 2 to 3 times, add urea in different mass ratios, Stirring was continued for 2 h, and then the water was evaporated to dryness at 50° C., and the obtained sample was dried in a vacuum oven for 12 hours for use. Put an appropriate amount of dried sample in a porcelain boat, put it in a tube furnace, raise the temperature to 800°C at a rate of 5°C / min under the protection of nitrogen, keep it warm for 2 hours, and then cool it down to room temperature naturally to obtain a black powder substance. Then add it to 20 mL of 0.5 mol / L H 2 SO 4 solution, stirred at 80°C for 8 hours, washed 2 to 3 times with deionized water, filtered with suction, and dried at 60°C for 12 hours.

[0023] Weigh the above samples, activated carbon, acetylene black and PTFE with a mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com